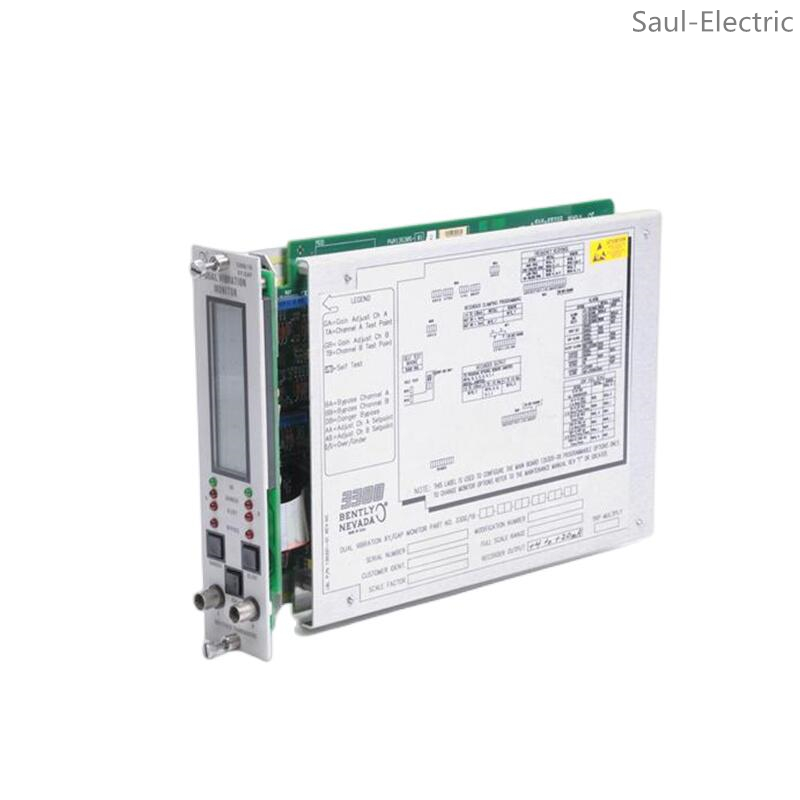

BENTLY 3300/16 modular system

BENTLY 3300/16

BENTLY 3300/16 is a modular system for monitoring the vibration status of rotating machinery equipment, which can monitor the radial vibration and shaft position clearance of the equipment in real time. It uses two proximity probes/Proximitors ® The system inputs, continuously detects and monitors two independent radial vibration channels and the average shaft position (clearance), and provides radial position clearance alarm function. This system has high precision and reliability, and is suitable for industrial environments that require highly accurate and reliable vibration monitoring.

parameter

Number of channels: 16 channels, capable of monitoring multiple vibration data simultaneously.

Frequency response: Users can program it to 4 to 4000 Hz (240 to 240000 cpm) or 1 to 600 Hz (60 to 36000 cpm), suitable for different devices and application requirements.

Power supply voltage: programmable to -24 Vdc or -18 Vdc.

Output type: Voltage or current output is proportional to the full range of the programming monitor.

Size: 120mm x 80mm x 40mm.

Working temperature range:- 40 ℃~85 ℃.

application area

BENTLY 3300/16 is widely used in multiple industrial fields, including but not limited to:

Petroleum and chemical industry: used to monitor the vibration of rotating equipment such as pumps, compressors, turbines, etc., and prevent equipment failures.

Power industry: used for vibration monitoring in power plants and substations to ensure the safe operation of power facilities.

Metallurgical industry: used for vibration monitoring of equipment such as rolling mills and blowers.

Paper, pharmaceutical, cement and other industries: used to monitor the vibration status of rotating machinery and equipment, improve production efficiency and equipment life.

advantage

High precision and reliability: BENTLY 3300/16 has high-precision data acquisition capabilities, ensuring the accuracy of data and stable operation in various harsh environments.

Multifunctionality: In addition to vibration monitoring, it also provides radial position gap alarm function, which can comprehensively monitor equipment status.

Flexibility and compatibility: Supports multiple communication protocols for remote monitoring and data transmission, and is compatible with multiple operating systems and hardware platforms.

Easy to install and maintain: simple structure, small size, light weight, easy maintenance, strong adaptability.

In summary, BENTLY 3300/16 is a powerful and reliable vibration monitoring system suitable for various industrial environments, which can significantly improve the safety and stability of equipment operation

Frequently Asked Questions (FAQ)

- Do you support product customization?

Yes, we offer customization services. We provide personalized solutions for design, specifications, and functionality based on the specific needs of our clients. - What is the delivery time?

Delivery times vary depending on the order quantity and product type. Typically, the delivery time for standard products is 7-15 business days. Custom products may require longer lead times. The exact delivery date can be confirmed when the order is finalized. - How can I track my order’s shipping status?

We offer real-time tracking services. Clients can track the status of their shipment anytime using the provided tracking number to ensure timely delivery. - Do you offer international shipping?

Yes, we have a well-established international logistics network. We can ship products safely and efficiently to any part of the world through sea freight, air freight, and other methods. - Are your products environmentally friendly?

Our products meet international environmental standards. We use eco-friendly materials and adhere to sustainable development principles to minimize the environmental impact during production and use. - What payment methods do you accept?

We support various payment methods, including bank transfers, wire transfers, and more. The specific payment method can be confirmed during the ordering process. - Do you offer after-sales services?

Yes, we provide comprehensive after-sales services, including handling product quality issues, technical support, and maintenance services. Customers can contact our after-sales team anytime for assistance. - What is the minimum order quantity?

The minimum order quantity depends on the product type. Please contact our sales team to get accurate information regarding your order requirements. - What is the product warranty period?

Our products generally come with a 1-year warranty, though this may vary for different products. Detailed warranty terms can be confirmed at the time of purchase. - How can I contact customer service?

You can contact our customer service team by phone, email, or through our online customer support platform. Our team is ready to provide timely assistance and support.

These answers cover the most common inquiries from our customers. If you have any further questions, please feel free to reach out to ourcustomer service team.

Bentley main series

| Bently Nevada 84143-01 XDCR I/O AND Record Terminal |

| Bently Nevada 84157-01 Signal Input/Alarm Output Module |

| Bently Nevada 86497-XX-XX-01-00 Interface Module |

| Bently Nevada 88286-02E Interface Module |

| Bently Nevada 89417-01 Signal Input/Alarm Output Module |

| Bently Nevada 990-04-50-02-01 Vibration Transmitter |

| Bently Nevada 990-04-70-01-00 2-Wire Vibration Transmitter |

| Bently Nevada 990-05-50-02-01 Vibration Transmitter |

| Bently Nevada 990-05-70-01-01Vibration Transmitter |

| Bently Nevada PWA101879-01 Module |

| Bently Nevada PWA103928-02 Transient Data Interface Module |

| Bently Nevada PWA123447-01 Transient Data Interface |

| Bently Nevada PWA134652-01 TDXnet PLC Transient Data Interface |

| BENTLY 60M100-00 Wind Condition Monitoring |

| BENTLY 126599-01 Module Internal Terminations |

| Bently 3500/22-01-01-00 Transient Data Interface |

| Bently 125840-02 Low Voltage AC Power Input Module |

| Bently 3500/33-01-00 16-Channel Relay Module |