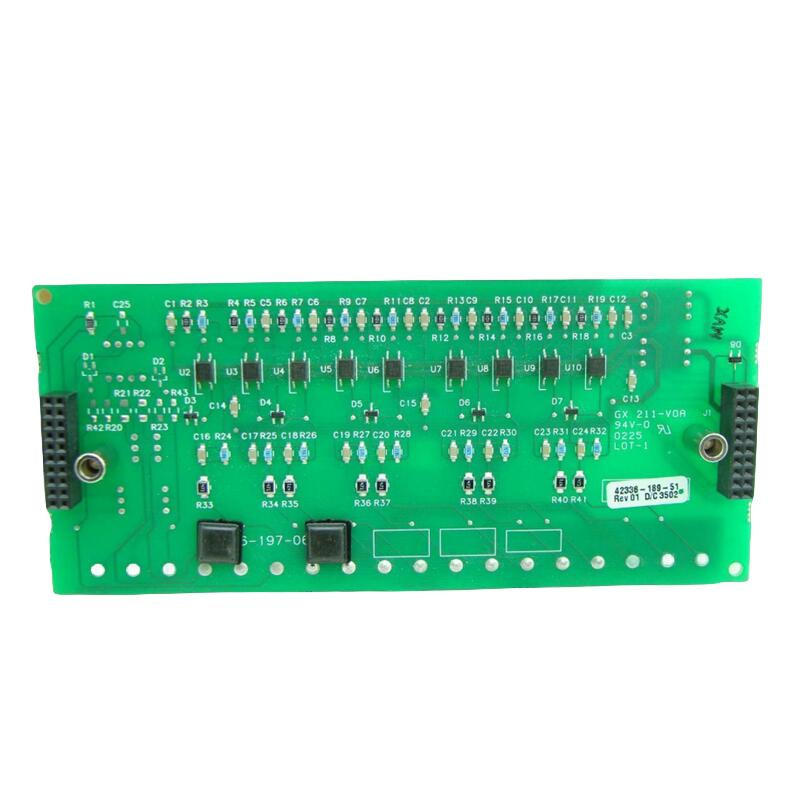

Allen-Bradley 1336-QOUT-SP17A Digital Output Module

Allen-Bradley 1336-QOUT-SP17A

1. Overview

2. Specifications

|

Specification

|

Typical Value

|

Unit

|

Remarks

|

|---|---|---|---|

|

Applicable Voltage Range

|

110 – 240 V

|

-

|

Suitable for most industrial standard voltages

|

|

Output Current Capacity

|

10 – 15 A

|

-

|

Capable of supporting testing needs of common inverters

|

|

Display Accuracy

|

±0.5%

|

%

|

High-precision display

|

|

Display Type

|

LCD

|

-

|

Multilingual display, easy to read

|

|

Power Supply

|

Alternating Current (AC)

|

V

|

Built-in power adapter

|

|

Dimensions

|

197.0 x 171.5 mm

|

-

|

Portable design

|

|

Weight

|

Approx. 1.5 kg

|

-

|

Lightweight and easy to carry

|

________________________________________________________________________________________________________________________________

3. Product Features

- Portable Design: Compact size (approx. 20cm x 17cm) and lightweight, convenient for on-site carrying and use.

- High-Precision Detection: Equipped with built-in high-precision sensors and signal conditioning circuits to ensure the accuracy of output waveform and parameter measurement.

- Multifunctional Display: Supports displaying multiple key parameters such as voltage, current, frequency, and waveform distortion.

- High Safety: Features overload protection and short-circuit protection functions, ensuring safe and reliable use.

- Strong Compatibility: Customized for 1336 series inverters, capable of accurately reading and parsing the communication protocols and data formats of this series of equipment.

________________________________________________________________________________________________________________________________

4. Structure and Composition

|

Component

|

Function

|

|---|---|

|

Display Panel

|

LCD display screen, real-time display of test results, waveforms, and parameter values.

|

|

Input/Output Interface

|

Interface for test leads connected to the inverter’s output terminal (usually 3-pin or 4-pin plug).

|

|

Operation Knob

|

Used for selecting test modes, adjusting parameters, and browsing menus.

|

|

Power Adapter

|

AC power input module, providing the working voltage required by the instrument.

|

|

Protective Enclosure

|

Metal or high-strength plastic enclosure, preventing static electricity and external interference.

|

________________________________________________________________________________________________________________________________

5. Application Areas

- Inverter Maintenance: Used to quickly check the quality of inverter output during factory or on-site maintenance.

- Troubleshooting: Locates the causes of inverter faults, such as output waveform distortion and parameter drift.

- Factory Inspection: Used for quality control before inverter delivery, ensuring the output performance of each device meets standards.

- Technical Support: An essential tool for Rockwell Automation technicians when providing on-site technical support to customers.

________________________________________________________________________________________________________________________________

6. Installation and Maintenance

- Unboxing Inspection: Check if the instrument enclosure is damaged and if accessories (test leads, adapter, user manual) are complete.

- Connecting Test Leads: Connect the input interface of the tester to the output terminal of the 1336 series inverter, ensuring a secure connection.

- Power Connection: Plug the instrument into a power socket and turn on the power switch.

- Parameter Setting: Select the test mode as needed (such as voltage test, current test, or waveform analysis).

- Reading Results: Observe the real-time values and waveforms on the LCD display and record abnormal data.

- Daily Maintenance: Unplug the test leads after use, regularly wipe the instrument surface with a dry cloth, and avoid storing in a humid environment.

————————————————————————————————————-

If you would like to learn more about our products and services, please feel free to contact us at any time!

- Sales Manager : Jinny

- Email : sales5@xrjdcs.com

- Whatsapp/Mobile:+86 15359273791

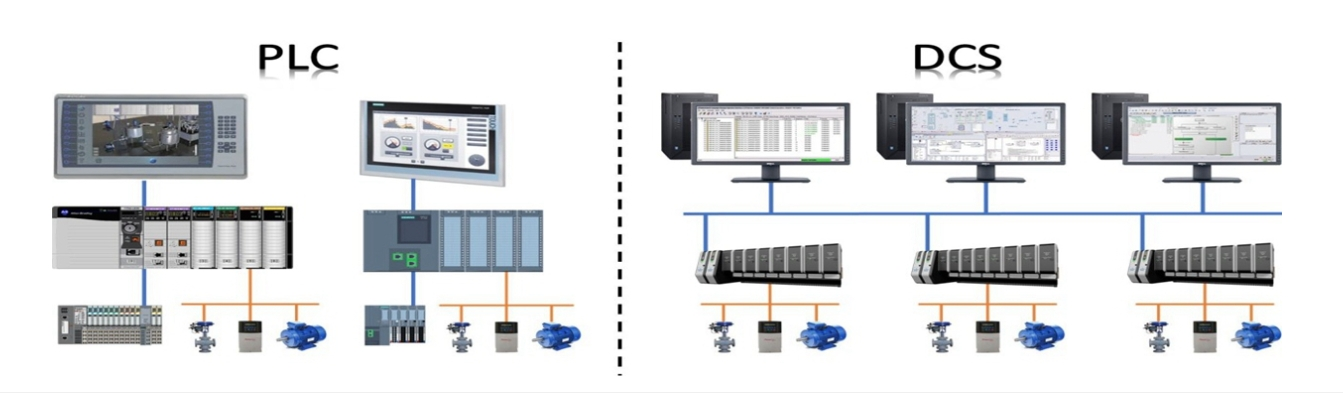

Global renowned brand cooperation

ABB 丨 GE 丨Allen Bradley 丨 Honeywell 丨 Emerson 丨 Bently Nevada 丨 Westinghouse

Triconex 丨 Foxboro 丨 ICS Triplex 丨 Hima 丨 Schneider 丨 Yokogawa 丨 Woodward

—————————————————————————————

________________________________________________