Welcome to our websites!

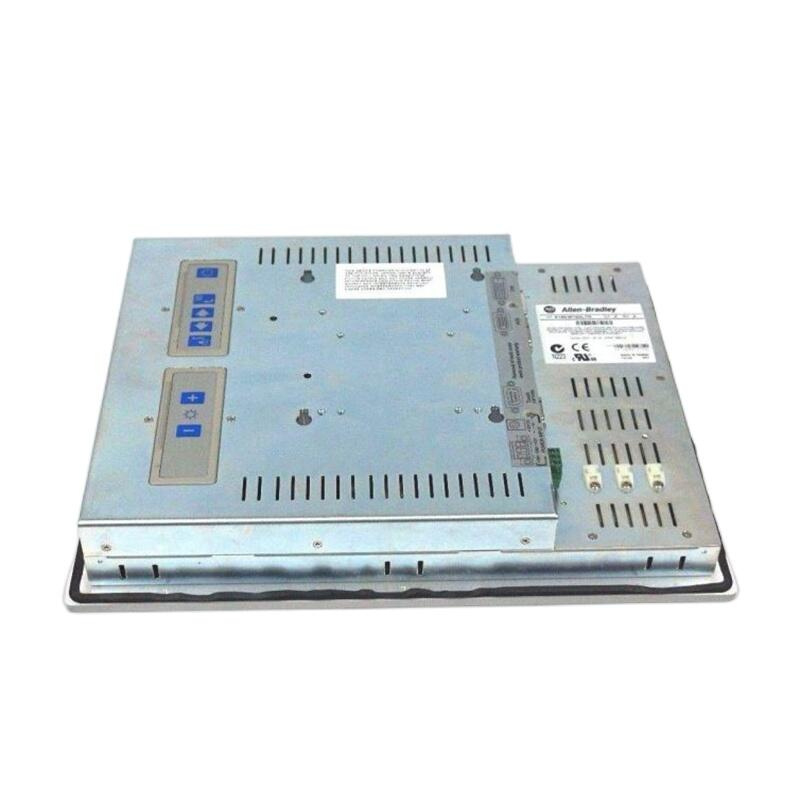

Allen-Bradley 1336-MOD-KB010 Control Module

Allen-Bradley 1336-MOD-KB010

1. Product Overview

The Allen‑Bradley 1336‑MOD‑KB010 is a control module specifically designed for the 1336 Series AC drives. It is primarily used for drive monitoring, parameter configuration, fault diagnosis, and communication with higher‑level systems such as PLCs, HMIs, or DCS.

- Product Category: Industrial automation control, specifically for motor drives and process control.

- Typical Applications: Widely used in mechanical drive systems across industries such as oil and gas, chemical processing, power generation, metallurgy, pulp and paper, and food processing.

________

2. Key Parameters and Technical Specifications

- Series Compatibility: Typically used with 1336F Series (e.g., 1336F‑BRF20‑AA‑EN‑L4) and 1336S Series (e.g., 1336S‑BRF30‑AA‑EN‑L6) drives.

- Power Range: The 1336 Series drives cover a power range from approximately 10 HP (7.5 kW) up to 500 HP (375 kW).

_________

3. Product Features

- High Reliability: Allen‑Bradley products are well‑recognized in industrial automation for their proven stability and long service life.

- Modular Design: Easy replacement and maintenance, allowing users to add or change control modules based on specific application needs.

- Advanced Control Technology: Supports multiple vector control methods (such as FOC and DTC), as well as high‑precision torque and speed control.

__________

4. Structure and Components

- Power Module: Delivers the drive power to the motor.

- Control Board: Receives commands, executes control algorithms, and manages output signals.

- Communication Interfaces: Such as Modbus, Ethernet/IP, and DeviceNet for seamless integration with PLCs and factory networks.

- Cooling System: Ensures proper heat dissipation for reliable operation in harsh industrial environments.

_____________

5. Application Areas

- Pump Systems: Water supply, oil transfer, and heating pumps.

- Fans and Blowers: Industrial ventilation and dust collection systems.

- Conveyors and Hoists: Mining, port, and logistics material handling.

- Mixing and Agitation: Chemical, pharmaceutical, and food processing equipment.

________________

6. Installation and Maintenance

- Installation Requirements: Should be mounted in a dry, well‑ventilated environment, protected from moisture and excessive dust.

- Maintenance: Supports remote monitoring and diagnostics. Users can adjust parameters and troubleshoot faults via software such as RSLogix and FactoryTalk.

- Protection Features: Includes overload, overcurrent, overheating, and short‑circuit protection to ensure safe operation and minimize downtime.

————————————————————————————————————-

If you would like to learn more about our products and services, please feel free to contact us at any time!

- Sales Manager : Jinny

- Email : sales5@xrjdcs.com

- Whatsapp/Mobile:+86 15359273791

Global renowned brand cooperation

ABB 丨 GE 丨Allen Bradley 丨 Honeywell 丨 Emerson 丨 Bently Nevada 丨 Westinghouse

Triconex 丨 Foxboro 丨 ICS Triplex 丨 Hima 丨 Schneider 丨 Yokogawa 丨 Woodward

—————————————————————————————

When you choose us, you’ll benefit from the following advantages:

• One‑stop shopping: We offer a wide range of industrial control products to meet all your procurement needs.

• Professional solutions: Our technical team tailors the optimal solution for your specific requirements.

• Exceptional service: We provide comprehensive pre‑sales, during‑sales, and after‑sales support.

• 20+ years of industry experience

• Authorized distributor for many well‑known brand

• Extensive product line covering multiple industries

• Professional technical team offering full‑range support

• Comprehensive after‑sales service system to protect your interests

We warmly welcome you to contact us by phone or email for inquiries.

Write your message here and send it to us