ATLAS PF3007-G-HW Single Tool Controller

ATLAS PF3007-G-HW

1. Overview

2. Core Parameters & Technical Specifications

|

Parameters

|

Specifications

|

|---|---|

|

Model

|

PF3007-G-HW (NSFP/Power Focus Tensor)

|

|

Control Capability

|

Supports 1 electric tightening tool (Nutrunner)

|

|

Communication Interfaces

|

PB model (such as PF3007-G-PB-HW) has a built-in Profibus interface; also supports USB, RS232, Ethernet (optional) and Open Protocol standard interfaces

|

|

Power Supply Range

|

100-240 VAC AC

|

|

Applicable Platform

|

Tensor S4/S7 (such as S4, S7, S8, etc.)

|

|

Software Version

|

Usually pre-installed with Open Protocol SW 1.2.10.27 or newer version

|

_______________________________________________________________________________________________________

3. Product Features

- High-Precision Control: It can realize precise control of various tightening strategies such as torque, angle, and torque-angle, which is suitable for tightening tasks of key bolts.

- Data Traceability: Supports the collection and storage of process data, facilitating the traceability of assembly quality and process control.

- Multiple Communication Protocols: Built-in Profibus (for PB models) or supports a variety of industrial communication protocols, which is convenient for integration with PLC and MES systems to achieve seamless connection of automated production lines.

- High Integration: As a hardware-activated version (HW), it usually includes necessary power management and interface circuits to adapt to the needs of different production environments.

_______________________________________________________________________________________________________

4. Structure & Composition

- Control Unit: The core processor board is responsible for real-time control of the operation of the electric tool.

- Power Module: Adapts to 100-240 VAC industrial power supply and provides stable working voltage.

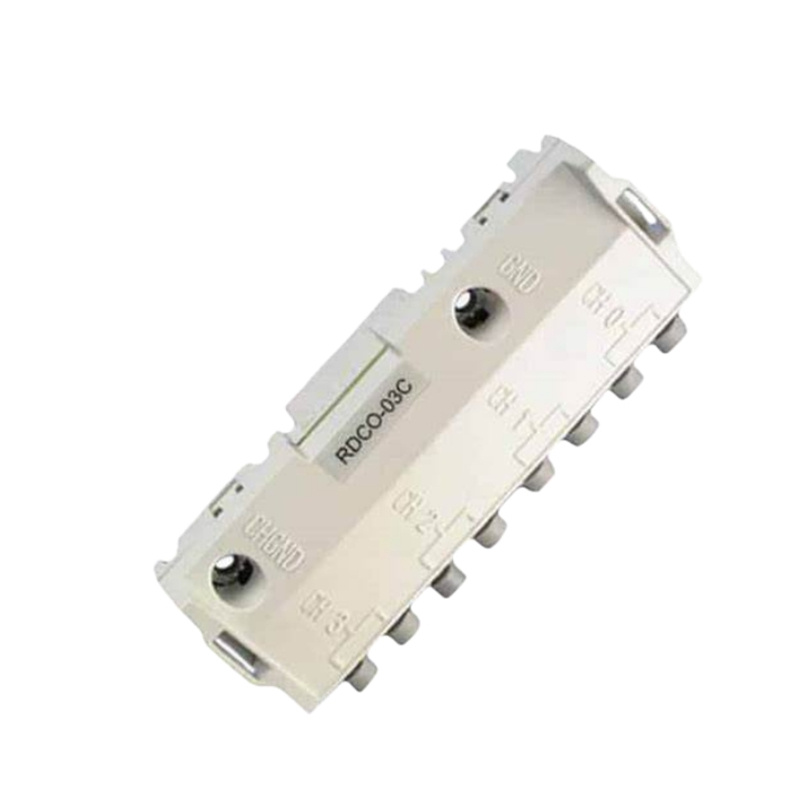

- Interface Module: Provides tool connection interface (for connecting Nutrunner) and communication interfaces (such as Profibus, USB, etc.).

- Housing: Usually adopts an industrial-grade metal housing, which meets the protection level standard (such as IP67) and is suitable for harsh industrial environments.

_______________________________________________________________________________________________________

5. Main Application Fields

Automotive Manufacturing

- Tightening of key bolts for engines, gearboxes, chassis and body structural parts.

- High-precision assembly of new energy vehicle power battery modules and electric drive systems.

Industrial Robot Automatic Tightening Workstations

- Integrated with robots to realize efficient and precise automatic tightening operations.

Construction Machinery & Rail Transit

- High-torque tightening of structural part connections, braking systems and suspension components.

Home Appliances & Electronic Manufacturing

- Suitable for small and medium-sized production lines with flexible varieties, such as the assembly of home appliances.

_______________________________________________________________________________________________________

6. Installation & Maintenance

Installation

- Usually installed in a control cabinet or on the rack of a workstation.

- Ensure that the power cord, communication cable (such as Profibus cable) and tool cable are correctly connected.

- Wiring according to the electrical drawings to ensure reliable grounding.

Maintenance

- Regularly check whether the connecting wires are loose or worn.

- Clean the dust and oil on the surface of the housing to prevent water and dust from entering and affecting heat dissipation.

- Regularly update the firmware through PC software or handheld devices to obtain the latest functions and repair patches.

————————————————————————————————————-

If you would like to learn more about our products and services, please feel free to contact us at any time!

- Sales Manager : Jinny

- Email : sales5@xrjdcs.com

- Whatsapp/Mobile:+86 15359273791

Global renowned brand cooperation

ABB 丨 GE 丨Allen Bradley 丨 Honeywell 丨 Emerson 丨 Bently Nevada 丨 Westinghouse

Triconex 丨 Foxboro 丨 ICS Triplex 丨 Hima 丨 Schneider 丨 Yokogawa 丨 Woodward

—————————————————————————————

Industrial Control Products & Services – Official Details

Shipping & Related Notes

- We always provide combined shipping discounts for multiple items. The final combined shipping rate will depend on the weight and size of the items.

- We will ship the goods within 1-3 working days after receiving the settlement payment.

- The daily cutoff time for express delivery shipment is 6:00 PM.

- We offer receiving services via TNT, DHL, UPS and FedEx.

- For international buyers: Import duties, taxes and charges are not included in the item price or shipping costs. These charges are the buyer’s responsibility. Please check with your country’s customs office to determine the amount of these additional charges before bidding or purchasing.