Welcome to our websites!

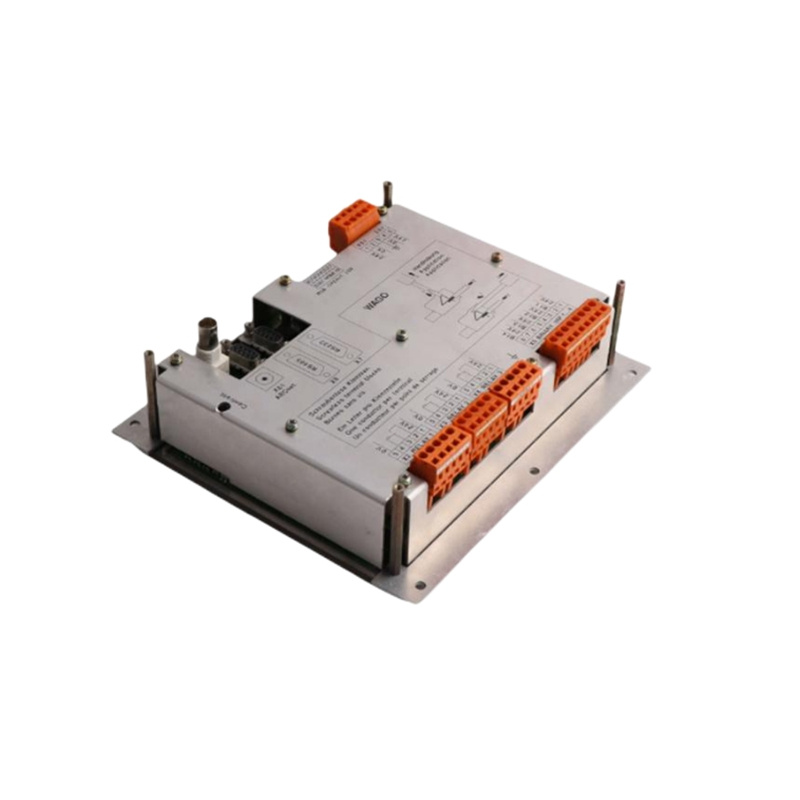

ATLAS PF3102-C-HW AC System Power Supply

ATLAS PF3102-C-HW

The PF3102-C-HW is a key controller in the Atlas Copco Power Focus 3100 series. Specifically designed to control the Tensor series electric bolt torque wrenches, it is responsible for performing high-precision torque and angle control tasks. Renowned for its compact structure and highly integrated control algorithms, this product is particularly suitable for use in automated production lines with limited space or distributed control requirements.

___________________________________________________________________________________________________________________________

Product Model Explanation

- PF3102: Indicates a 2-channel standard model belonging to the PF3100 series.

- C: Stands for Core configuration, featuring core control and communication functions.

- HW: Refers to Hardware version.

Core Product Features

Compact & Integrated Design

Highly integrated and compact in size, it is easy for embedded installation. It can adapt to small chassis or on-site environments, reducing space occupation effectively.

High-Precision Control

Custom-developed for Atlas Copco Tensor series bolt torque wrenches, it boasts extremely high torque control accuracy and repeat positioning accuracy, ensuring every tightening operation meets strict standards.

High Reliability

Adopting an industrial-grade design and protection level, it can operate stably in harsh workshop environments, reducing errors caused by environmental factors.

___________________________________________________________________________________________________________________________

Structure & Composition

- Power Management Module: Responsible for providing stable power to the controller itself, as well as connected sensors and actuators.

- CPU & DSP Processing Unit: The core control chip that executes torque calculation, position detection, and motion control algorithms.

- Communication Interfaces: Offers multiple industrial communication protocols (such as CANopen, Ethernet/IP, etc.) for data interaction with PLCs or upper computers.

- Terminal Blocks: Used to connect input/output signals of peripheral devices such as torque wrenches, sensors, and drivers.

- Display/Operation Interface (Some Models): May integrate a simple LCD display or indicator lights for on-site status display.

___________________________________________________________________________________________________________________________

Typical Application Fields

Automotive Manufacturing

Used for tightening engine bolts in automotive assembly lines, ensuring the connection strength of key parts (such as engine blocks and gearboxes).

Aerospace

Performs high-precision torque operations in aircraft fuselage assembly and engine maintenance.

Large Equipment Manufacturing

Applied in large-scale bolt tightening operations such as wind turbines, shipbuilding, and rail transit.

Automated Assembly Lines

Serves as a key node in automated production lines, linking with robotic arms or PLC systems.

___________________________________________________________________________________________________________________________

Installation & Maintenance Guidelines

Installation Recommendations

- Environmental Requirements: Install in a well-ventilated, dry environment away from direct sunlight. It is recommended to install it in a cabinet with a protection level of IP20 or higher.

- Fixing Method: Usually fixed by DIN rail or screws to ensure the controller is stable and does not shake, so as not to affect measurement accuracy.

- Wiring Specifications: Never reverse-connect the power cord; ensure the power is cut off before wiring. Arrange the terminals according to the wiring diagram to ensure correct connection of signal lines such as torque wrenches and sensors.

Daily Maintenance

- Cleaning & Maintenance: Regularly remove dust inside the control box, keep the ventilation ports unobstructed, and prevent overheating.

- Connection Inspection: Regularly check the tightness of the terminal blocks to prevent poor contact caused by vibration.

- Firmware Update: It is recommended to regularly check if Atlas Copco officially releases controller firmware update packages and update them in a timely manner to obtain better performance and security patches.

About Atlas Copco

Atlas Copco is a world-leading provider of sustainable productivity solutions. With decades of experience in industrial equipment research and development, we are committed to delivering high-quality, reliable products to help customers improve production efficiency and reduce operational costs. The Power Focus 3100 series controllers embody our pursuit of precision and innovation, serving various industries worldwide.

————————————————————————————————————-

If you would like to learn more about our products and services, please feel free to contact us at any time!

- Sales Manager : Jinny

- Email : sales5@xrjdcs.com

- Whatsapp/Mobile:+86 15359273791

Global renowned brand cooperation

ABB 丨 GE 丨Allen Bradley 丨 Honeywell 丨 Emerson 丨 Bently Nevada 丨 Westinghouse

Triconex 丨 Foxboro 丨 ICS Triplex 丨 Hima 丨 Schneider 丨 Yokogawa 丨 Woodward

—————————————————————————————

Our Advantages & Service – Product Details

Our Core Advantages

All our products arebrand-new and original, with a one-year quality guarantee and professional after-sales service! Every product of our company has passed strict quality inspection before delivery to ensure stable performance and reliable quality.

We warmly welcome your inquiry and purchase. As long as you have sincere cooperation intentions, we will provide you with a more competitive price than our peers, and we will win orders together!

We Focus on Hard-to-Find Spare Parts

If you are looking for the following types of spare parts, please feel free to contact us — we have rich channels to meet your needs:

- Uncommon spare parts

- Rare spare parts

- Discontinued spare parts

Why Our Products Have More Price Advantages?

- Source purchasing: We purchase directly from the original factory, eliminating price differences caused by intermediate links and reducing your procurement costs.

- Stable channels: We have long-term and stable cooperative relationships with many well-known manufacturers, ensuring sufficient supply and more reliable product sources.

Delivery Time

- In-stock products: After signing the contract and completing the payment, we will arrange delivery immediately.

- Custom-ordered products: Delivery will be arranged in accordance with the quoted delivery time.

Sincere cooperation, win-win together! For any inquiry, please contact us without hesitation.

Write your message here and send it to us