EMERSON MMS3210/022-000 Vibration Analyzer

EMERSON MMS3210/022-000

The A3120/022‑000 is a portable rotating machinery vibration analyzer launched by Emerson, belonging to its CSI product series. Specifically designed for on-site predictive maintenance, this instrument enables fast and accurate acquisition of key operating condition data of rotating equipment—such as vibration, temperature, and rotational speed—and helps technicians assess the health status of components (e.g., bearings, gears, pumps, and compressors) through built-in diagnostic algorithms.

Main Technical Specifications

| Specification Category | Details |

|---|---|

| Measurement Range | Vibration acceleration: ±50 g (optional); Velocity: ±100 mm/s; Displacement: ±200 μm |

| Frequency Range | 0.5 Hz ~ 10 kHz (acceleration channel); 0.5 Hz ~ 5 kHz (velocity/displacement channel) |

| Sampling Rate | Up to 25 kS/s (dual-channel synchronous sampling) |

| Input Channels | Dual channels for acceleration/velocity/displacement; compatible with piezoelectric or electromagnetic sensors (each channel can be connected separately) |

| Display Screen | 5.7-inch color touch LCD with a resolution of 800 × 480 pixels |

| Storage Capacity | Internal 8 GB SSD, capable of storing thousands of measurement records |

| Communication Interfaces | USB-C, Ethernet (Modbus/TCP, EtherNet/IP), Bluetooth, Wi-Fi |

| Power Supply | Rechargeable lithium battery (approximately 8 hours of continuous operation); external 12 V/24 V DC power adapter |

| Operating Environment | Temperature: –20 °C ~ +60 °C; Protection Class: IP54; Shock Resistance: 15 g |

Product Features

- High-Precision, Multi-Channel Synchronous Measurement: The dual-channel design enables simultaneous monitoring of vibration in two axes or at different locations, ensuring data integrity.

- Built-in Self-Test and Fault Indication: The instrument is equipped with self-test functions for sensors and circuits. In case of anomalies, it automatically switches output status and displays prompts on the screen.

- Powerful Diagnostic Algorithms: Preloaded with templates for common fault modes (e.g., bearing defects, gear issues, unbalance, and looseness) to support rapid fault localization.

- On-Site Plug-and-Play: Modular structure allows deployment with standard piezoelectric/electromagnetic sensors, no additional calibration required.

- Multi-Protocol Communication: Compatible with mainstream industrial networks, facilitating integration with DCS, SCADA, and MES systems for remote monitoring and data reporting.

- Durable and Rugged: Complies with IP54 protection standards and features shock-resistant design, suitable for harsh on-site environments (e.g., high noise, dust, and humidity).

Structure and Components

- Main Chassis: Metal housing integrating a main control CPU, DSP processor, storage module, and display/touch panel.

- Input Module: Two optional input cards for acceleration/velocity/displacement signals, equipped with replaceable preamplifiers.

- Power Supply System: Built-in lithium battery compartment and external power interface, with a power management chip to enable fast charging and discharging.

- Communication Board: Modules for Ethernet, USB-C, and Bluetooth/Wi-Fi antennas, supporting multi-protocol stacking.

- Brackets/Mounting Parts: Standard anti-vibration brackets and quick-lock buckles provided for on-site fixing or handheld use.

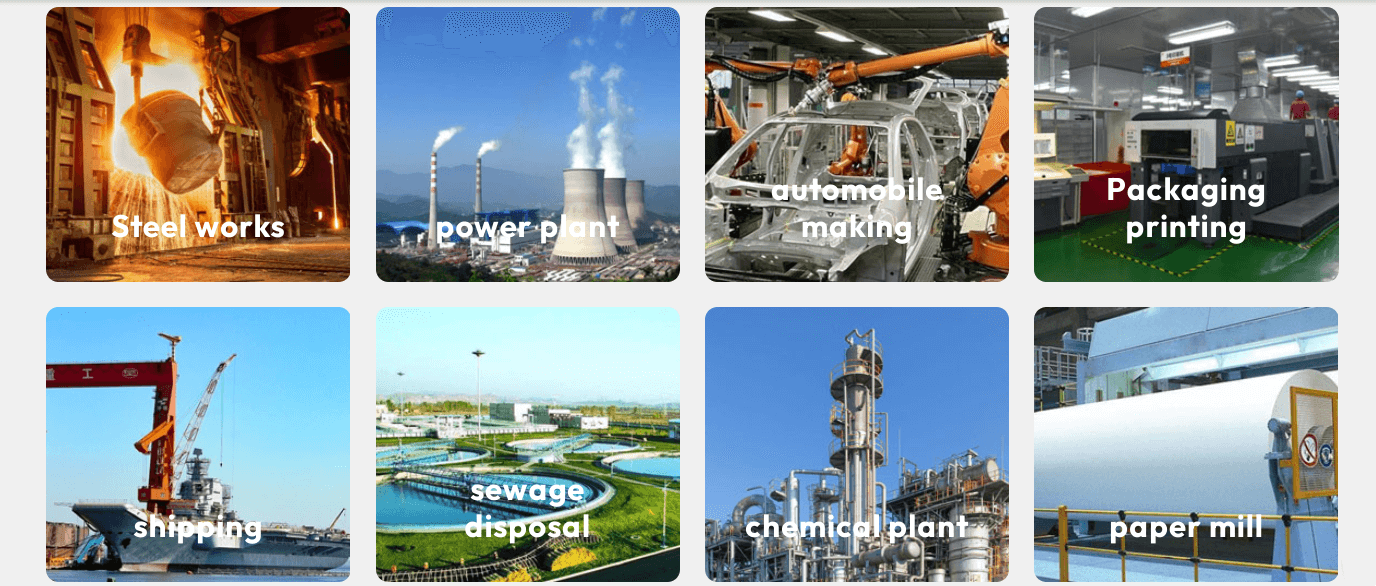

Typical Application Fields

- Power Plants: Vibration monitoring and fault early warning for steam turbines, generator bearings, and gas turbines.

- Petrochemical & Chemical Industries: Condition monitoring of pumps, compressors, and heat exchangers to prevent leaks or shutdowns caused by vibration.

- Metallurgy & Mining: Vibration analysis of large fans, grinding mills, and conveyor systems.

- Manufacturing: Routine maintenance of CNC machine tools, gearboxes, and transmission systems.

- Ships & Offshore Platforms: Vibration diagnosis of main engines and propeller shafts to enhance offshore operation safety.

Key Points for Installation and Maintenance

- On-Site Layout: Use anti-vibration brackets to fix the instrument on a stable platform. Ensure the coupling surface between the sensor and the measured bearing is clean and free from looseness.

- Power Check: Before first use, confirm the battery is fully charged or connect an external power supply that meets specifications; check if the power indicator light functions normally.

- Sensor Calibration: Perform zero-point calibration based on the sensor type (piezoelectric or electromagnetic). If necessary, use the instrument’s built-in calibration tools for on-site calibration.

- Software Upgrade: Regularly download the latest firmware and diagnostic algorithms via USB-C or network interfaces to ensure up-to-date functionality and security.

- Regular Self-Test: It is recommended to run the instrument’s built-in self-test function monthly to check the health status of sensor channels, storage media, and communication interfaces.

- Cleaning & Protection: Keep the chassis vents free from dust accumulation to prevent poor heat dissipation; use a protective cover when operating in humid or dusty environments.

- Data Recording & Backup: Regularly export measurement data to enterprise servers or cloud platforms to facilitate long-term trend analysis and auditing.

————————————————————————————————————-

If you would like to learn more about our products and services, please feel free to contact us at any time!

- Sales Manager : Jinny

- Email : sales5@xrjdcs.com

- Whatsapp/Mobile:+86 15359273791

Global renowned brand cooperation

ABB 丨 GE 丨Allen Bradley 丨 Honeywell 丨 Emerson 丨 Bently Nevada 丨 Westinghouse

Triconex 丨 Foxboro 丨 ICS Triplex 丨 Hima 丨 Schneider 丨 Yokogawa 丨 Woodward

—————————————————————————————

About Our Company

Core Business & Competitive Strengths

- Spare Parts Provision: Boasting an extensive spare parts inventory, we excel at rapid response to customer demands, offering components from leading brands like ABB, FOXBORO, and TOSHIBA.

- Customized System Integration: Our engineering team, equipped with profound experience in system integration, tailors automation system solutions to align with customers’ specific on-site requirements, ensuring optimal performance.

- Professional Technical Support: We deliver comprehensive technical services, including system debugging, fault diagnosis, and maintenance. These services are designed to safeguard the stable and uninterrupted operation of customers’ production lines.

- Swift Service Response: A well-established logistics network enables us to guarantee timely delivery of spare parts, minimizing the downtime of customers’ equipment and reducing potential losses.

- Competitive Pricing: By forging direct partnerships with original equipment manufacturers (OEMs) and streamlining our supply chain processes, we are able to offer customers cost-effective pricing without compromising on product quality.

- A portfolio of over 100 trusted brands to choose from

- Access to more than 551,867 unique product SKUs

- Global expedited delivery services to meet urgent needs

- Dedicated attention and full operational commitment to every project