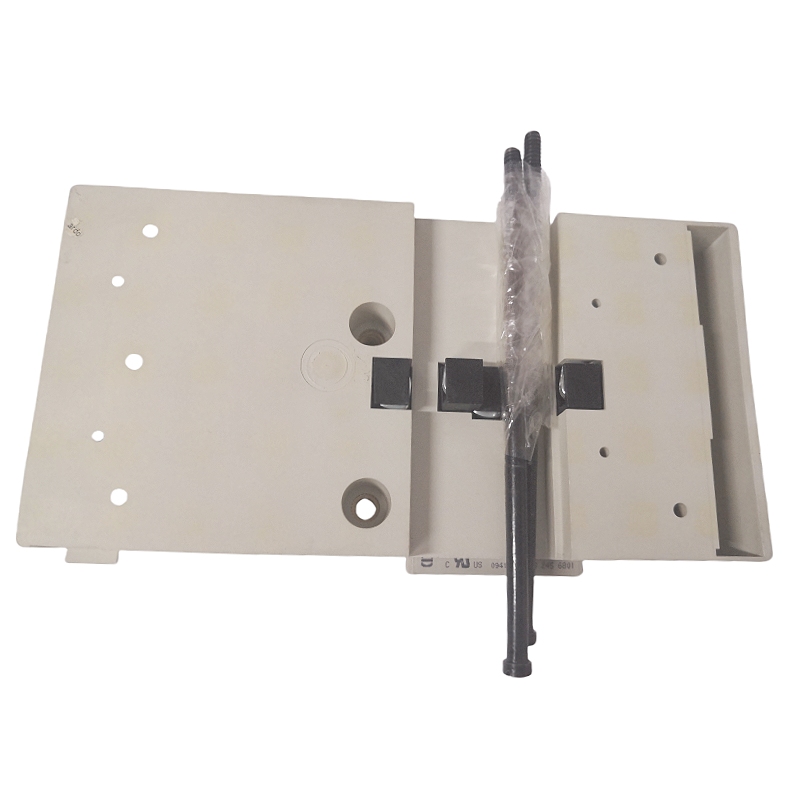

GE 8724-CA-PS power module

GE 8724-CA-PS

GE 8724-CA-PS is a dedicated power supply module under General Electric (GE), designed for its iconic Mark VIe gas turbine control system or other Mark series control platforms. As a critical component in the Mark VIe safety chain and control system cabinet, this module converts externally input AC or DC power into stable and reliable low-voltage DC power required by the control system. Specifically engineered for extremely harsh industrial environments, GE 8724-CA-PS features outstanding reliability, redundancy capability, and fail-safe characteristics—all of which are vital for ensuring the safe and stable operation of large rotating machinery such as gas turbines and steam turbines. Its core value lies in providing continuous and pure “power blood” for the entire protection and control logic circuit: even in the event of external power supply fluctuations or partial failures, the system can still execute a safe shutdown or maintain stable operation. This makes it a fundamental guarantee for 7×24-hour uninterrupted operation in key industries such as power generation and oil & gas.

Product Parameters

- Product Model: 8724-CA-PS

- Manufacturer: GE (General Electric)

- Product Type: Dedicated power supply module (for control systems such as Mark VIe)

- Input Voltage: Typically 125 VDC or 120 VAC (varies by ordered model)

- Output Voltage: +5 VDC, ±15 VDC, +24 VDC, +48 VDC (multiple outputs)

- Rated Output Power: 150 Watts or 300 Watts (varies by version)

- Redundancy Support: Yes, supports N+M redundancy configuration

- Cooling Method: Conduction cooling or forced air cooling

- Operating Temperature: -40°C to +70°C (wide temperature range)

- Certifications: cULus, ATEX, IECEx, CE (meets strict industrial and hazardous area requirements)

- Condition Monitoring: Equipped with integrated status and fault diagnosis output signals

Structure and Composition

Key Features and Advantages

- Extreme Reliability and Ruggedness: GE 8724-CA-PS is designed for mission-critical applications, adopting military-grade or aerospace-grade components and design standards. Its wide operating temperature range (-40°C to +70°C) and strong resistance to vibration and shock ensure fault-free continuous operation even in the harshest electrical and physical environments of power plants.

- Advanced Redundancy and Fault-Tolerant Architecture: The module supports true N+M hot redundancy configuration. Multiple power modules operate in parallel, sharing the load evenly. If any module fails, the remaining modules immediately and seamlessly take over the full load, achieving zero-switching-time failover. This provides the highest level of power availability for critical control systems like Mark VIe and completely eliminates the risk of single-point failure.

- Comprehensive Diagnostics and Monitoring Capabilities: The module has built-in precision diagnostic circuits that can real-time monitor input voltage, each output voltage, load current, and internal temperature. It not only provides local status indication via front-panel LEDs but also sends “power good” or “fault” status signals to the system controller through hardwiring, enabling remote centralized monitoring and early warning for predictive maintenance.

- Multiple Isolated Outputs: A single 8724-CA-PS module can provide multiple isolated DC voltages required by the system (e.g., +5V, ±15V, +24V, +48V) to power controller logic circuits, analog I/O modules, relays, and communication devices respectively. This integrated design simplifies cabinet layout, reduces connection points, and improves the overall reliability of the system.

Application Fields

Installation and Maintenance

Pre-Installation Preparation

Maintenance Recommendations

————————————————————————————————————-

If you would like to learn more about our products and services, please feel free to contact us at any time!

- Sales Manager : Jinny

- Email : sales5@xrjdcs.com

- Whatsapp/Mobile:+86 15359273791

Global renowned brand cooperation

ABB 丨 GE 丨Allen Bradley 丨 Honeywell 丨 Emerson 丨 Bently Nevada 丨 Westinghouse

Triconex 丨 Foxboro 丨 ICS Triplex 丨 Hima 丨 Schneider 丨 Yokogawa 丨 Woodward

—————————————————————————————

Xiamen Xingruijia Import and Export Co., Ltd.

- We always provide combined shipping discounts for multiple items. The final combined shipping rate will depend on the weight and size of the products.

- We will ship the goods within 1-3 working days after receiving the payment.

- The daily cutoff time for express delivery shipments is 6:00 PM. We arrange product delivery via TNT, DHL, UPS, and FedEx.

- For international buyers: Import duties, taxes, and charges are not included in the product price or shipping costs. These fees shall be borne by the buyer.

Please consult your country’s customs office to confirm the amount of these additional fees before placing a bid or making a purchase.