Welcome to our websites!

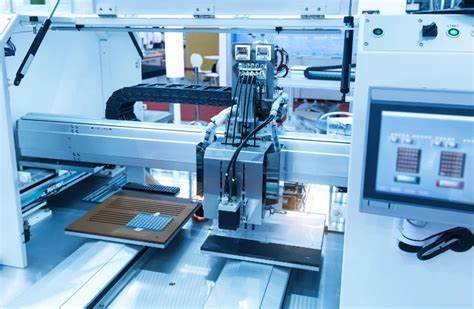

GE A16B-2203-0331 servo control module

GE A16B-2203-0331

Product Overview

The GE A16B-2203-0331 is a high-performance servo control module designed by FANUC (a subsidiary of General Electric, GE) for Computer Numerical Control (CNC) systems. As a core component of the FANUC Series 16/18/21 CNC systems, this module is specifically responsible for the precise control and motion management of servo motors. In CNC machine tool control systems, the GE A16B-2203-0331 plays a critical role: it receives instructions from the NC (Numerical Control) main board, generates precise servo control signals, and drives servo motors to achieve high-precision positioning and motion control of machine tool axes.

Its core value lies in delivering exceptional motion control performance and reliability. The module adopts advanced digital signal processing technology and precise control algorithms, enabling micron-level position control accuracy to ensure the high quality of machined workpieces. The GE A16B-2203-0331 module is equipped with strong adaptive control capabilities, which can automatically compensate for errors in mechanical systems and temperature drift, maintaining long-term stability. Additionally, it features comprehensive diagnostic and protection functions: it can real-time monitor the status of the servo system, and promptly take protective measures in case of overload, overheating, or abnormal conditions to prevent equipment damage. As a key component of CNC systems, the GE A16B-2203-0331 is widely used in high-precision machining fields and serves as a core guarantee for the reliable operation and machining accuracy of CNC machine tools.

Product Parameters

- Product Model: A16B-2203-0331

- Manufacturer: GE Fanuc

- Product Type: Servo Control Module

- Applicable System: FANUC Series 16/18/21

- Number of Control Axes: 2 Axes

- Control Method: Digital Servo Control

- Resolution: 0.0001mm

- Control Cycle: 125μs

- Feedback Interface: Absolute/Incremental Encoder Interface

- Communication Interface: High-Speed Serial Bus

- Power Supply Voltage: 24V DC ±10%

- Operating Temperature: 0°C to 55°C

- Storage Temperature: -20°C to 75°C

- Protection Class: IP2X

- Weight: 0.5kg

Structure and Composition

The GE A16B-2203-0331 module adopts a compact industrial-grade design, enclosed in a robust metal housing that provides excellent electromagnetic shielding and heat dissipation performance. The front of the module is equipped with multiple groups of status indicator lights, including power status, operation status, and alarm indicators, which provide operators with intuitive system status information. The rear of the module is connected to the system backplane via high-density connectors, enabling connections with the NC main board, servo amplifiers, and encoders.

Internally, the module uses a multi-layer circuit board design and mainly consists of the following core components: a high-performance Digital Signal Processor (DSP) responsible for executing complex servo control algorithms; an FPGA (Field-Programmable Gate Array) chip that processes high-speed encoder feedback signals and position control logic; a high-power IGBT (Insulated Gate Bipolar Transistor) drive circuit that generates servo motor control signals; a high-speed communication interface circuit that ensures real-time data exchange with other system components; and a comprehensive power management circuit that provides stable operating voltage for each component. These components work together through precise timing design and signal processing to jointly achieve high-precision and high-response servo control functions. The module also has a built-in temperature sensor and voltage monitoring circuit to ensure reliable operation even in harsh environments.

Application Fields

The GE A16B-2203-0331 module is specifically applied to various high-precision machining equipment using the FANUC Series 16/18/21 CNC systems. In the automotive manufacturing industry, it is used to control precision machining centers, turn-mill composite machines, and special-purpose processing equipment on engine production lines; in the aerospace field, it is used in 5-axis machining centers, impeller processing equipment, and composite material processing equipment; in the mold manufacturing industry, it is used in precision EDM (Electrical Discharge Machining) machines, high-speed milling centers, and precision grinding machines; in the general mechanical machining field, it is used in various CNC equipment such as lathes, milling machines, and drilling-tapping centers. By providing stable and reliable servo control, the GE A16B-2203-0331 ensures that these devices can achieve micron-level machining accuracy, meeting the requirements of modern manufacturing for high-quality and high-efficiency machining. It is an indispensable key control component in the field of precision manufacturing.

————————————————————————————————————-

If you would like to learn more about our products and services, please feel free to contact us at any time!

- Sales Manager : Jinny

- Email : sales5@xrjdcs.com

- Whatsapp/Mobile:+86 15359273791

Global renowned brand cooperation

ABB 丨 GE 丨Allen Bradley 丨 Honeywell 丨 Emerson 丨 Bently Nevada 丨 Westinghouse

Triconex 丨 Foxboro 丨 ICS Triplex 丨 Hima 丨 Schneider 丨 Yokogawa 丨 Woodward

—————————————————————————————

About Us: Your Trusted Partner for Imported Automation Spare Parts

Boasting years of dedicated expertise in the industrial automation sector, our company stands out as a professional supplier focused on the distribution of spare parts for large-scale imported control and robot systems. Our product portfolio covers core industrial systems, including Distributed Control Systems (DCS), Programmable Logic Controllers (PLC), Redundant Fault-Tolerant Control Systems, and Robot Systems—catering to the critical maintenance and operational needs of diverse industries.

As a high-tech enterprise integrating spare parts sales and system integration services, we have established stable partnerships with world-renowned automation brands. Our core brand offerings include ABB, Foxboro, Triconex, Bently Nevada, Ovation, Motorola, Xycom, A-B, Schneider, GE Fanuc, Yaskawa, Woodward, and more, ensuring we deliver authentic, high-performance components to our clients.

Our key product categories are tailored to meet comprehensive industrial automation requirements:

- PLC Controllers: We supply reliable PLC controllers and matching peripheral devices from leading brands such as ABB, Siemens, and Omron, supporting seamless control system operation.

- DCS System Spare Parts: Specializing in genuine spare parts for DCS systems, we cover brands like ABB, FOXBORO, and Honeywell to minimize downtime for industrial process control systems.

- Variable Frequency Drives (VFDs/Inverters): Our range includes high-efficiency inverters from ABB, Siemens, and Yaskawa, optimizing motor speed control and energy consumption for industrial equipment.

- Servo Motors: We offer precision servo motors from trusted brands such as Yaskawa and Panasonic, ensuring high accuracy and responsiveness for automated machinery.

- Sensors: Providing high-sensitivity sensors from ABB and Honeywell, our products enable real-time data collection and monitoring for industrial processes.

- I/O Modules: We deliver durable I/O modules from ABB and Siemens, facilitating stable signal transmission and connection between control systems and field devices.

Write your message here and send it to us