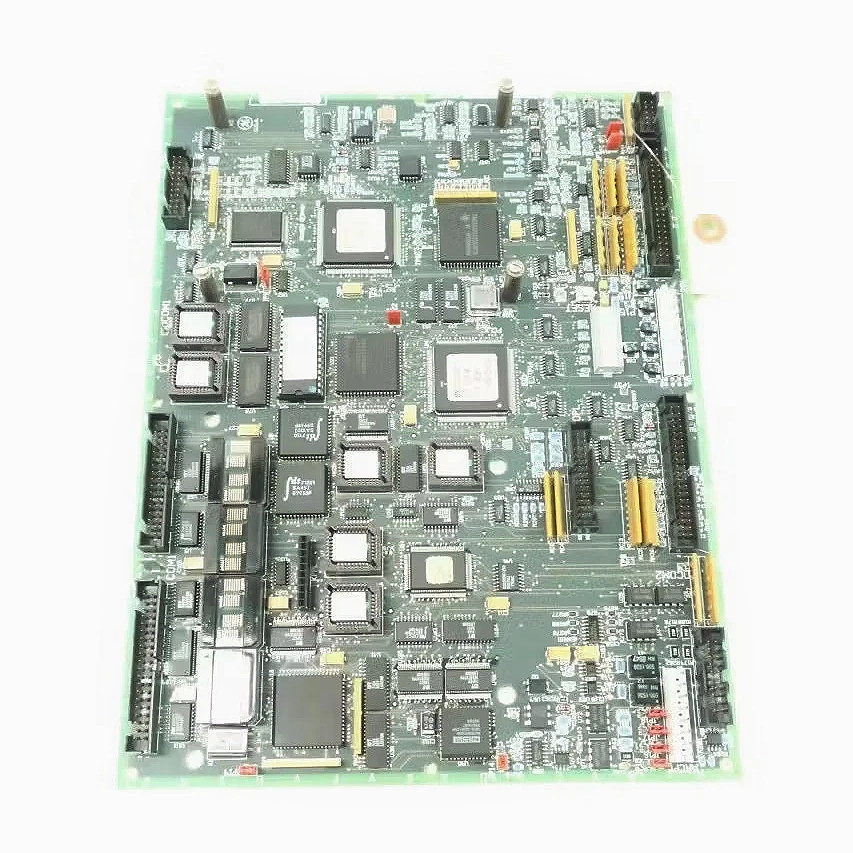

GE DS200LDCCH1APA Communication Board

GE DS200LDCCH1APA

The GE DS200LDCCH1APA is a Drive Control and Local Area Network (LAN) Communication Board (LDCC) in the General Electric (GE) Mark V series. It is specifically designed for DIRECTO-MATIC 2000 series drives and exciters, and plays a core role in drive control, I/O control, and network communication in gas turbines, steam turbines, and combined cycle power generation systems.

Key Technical Specifications

- Model/Part Number: DS200LDCCH1APA (also marked as DS200LDCCH1A)

- Series: Mark V (Speedtronic)

- PCB Layers: 7-layer PCB with conformal coating

- Processor: Four microprocessors, equipped with multiple flash memory modules and EEPROM for redundant backup

- Interfaces: 10 interfaces, supporting multiple bus systems such as RS-485, Ethernet (DLAN), C-bus, CPL, and Genius bus

- Power Supply: 24 V DC; Operating temperature range: -40 °C to 85 °C; Humidity: 5%–95%

- Dimensions/Weight: Approximately 220 mm × 165 mm × 25 mm; Weight: about 500 g (around 2 pounds)

- Functions: Drive control, speed/torque regulation, sensor input monitoring, operator command response, LAN communication, application software storage, diagnostic testing, and system reset

Product Features

- High Reliability: Adopts triple redundant backup and self-diagnostic functions, enabling automatic switching in case of faults to ensure continuous operation of critical turbine systems.

- Multi-Protocol Compatibility: Supports multiple industrial buses and Ethernet protocols, facilitating integration with DCS/PLC systems of different brands.

- Modular Design: Integrates drive, I/O, and communication functions on the board, simplifying system wiring and reducing maintenance costs.

- Easy Maintenance: Provides LED status indicators, remote diagnostic interfaces, and field-adjustable parameters to support rapid fault location and recovery.

- Wide Adaptability: Compatible with GE’s DIRECTO-MATIC 2000 series drives and exciters, suitable for gas turbines, steam turbines, wind power, oil energy, and other industrial scenarios.

Structure and Composition

- Core Circuit Board: 7-layer multi-layer PCB with a conformal coating on the surface to enhance environmental resistance.

- Microprocessor Array: Four microprocessors responsible for real-time control and communication tasks.

- Storage Unit: Includes multiple flash memory modules for program storage and EEPROM for parameter persistence.

- Interface Module: Provides RS-485, Ethernet, and multiple bus connection ports.

- Power Supply and Heat Dissipation: 24 V DC power input, equipped with heat sinks to ensure stable operation in high-temperature environments.

Typical Application Fields

- Power Plants: Drive and excitation control for gas turbines, steam turbines, and combined cycle systems.

- Oil and Gas Industry: Compressor drive, pump station control, and on-site monitoring.

- Wind Power Generation: Wind turbine drive control and remote diagnostics.

- Heavy Industries: Used for precise control and status monitoring of large motors and drive systems in chemical, paper, food and beverage industries.

Installation and Maintenance Points

Installation Preparation

- Verify the model and system compatibility, and ensure sufficient heat dissipation space inside the chassis.

- Check that the power supply voltage and grounding meet the specifications.

Mechanical Fixing

- Use original screws to fix the PCB on the rack to prevent solder joint loosening caused by vibration.

Wiring

- Correctly connect RS-485, Ethernet, and I/O ports according to the wiring diagram, and maintain good cable shielding to prevent electromagnetic interference.

Software Configuration

- Load the corresponding firmware and parameter files using the configuration tool provided by GE, and save them to EEPROM after on-site debugging.

Functional Self-Test

- After power-on, the on-board self-test program will light up the indicator lights to confirm that all microprocessors, communication interfaces, and power modules are working normally.

Regular Maintenance

- Check the tightness of connectors, clean dust, and measure the board temperature every 6 months.

- Use remote diagnostic functions to read fault logs and replace potentially aging components in advance.

Spare Parts Management

- Since this model has been discontinued, it is recommended to establish a spare parts inventory at the initial stage of the project to ensure quick replacement when needed.

————————————————————————————————————-

If you would like to learn more about our products and services, please feel free to contact us at any time!

- Sales Manager : Jinny

- Email : sales5@xrjdcs.com

- Whatsapp/Mobile:+86 15359273791

Global renowned brand cooperation

ABB 丨 GE 丨Allen Bradley 丨 Honeywell 丨 Emerson 丨 Bently Nevada 丨 Westinghouse

Triconex 丨 Foxboro 丨 ICS Triplex 丨 Hima 丨 Schneider 丨 Yokogawa 丨 Woodward

—————————————————————————————

Your Reliable Partner for Customized Automation Solutions

Why Partnering with Us Adds Value to Your Business

- Superior Quality Assurance: Every product and solution undergoes strict quality checks to meet industry-leading standards, minimizing operational risks for your business.

- On-Time Delivery Commitment: We prioritize efficient supply chain management to ensure your orders are delivered promptly, avoiding delays in your production or project timelines.

- Extensive Range of Branded Components: We stock and supply a wide selection of parts from well-known, reputable brands, guaranteeing compatibility and durability.

- Expert Team & Advanced Testing Facilities: Our team of seasoned professionals, combined with state-of-the-art testing equipment, ensures every solution is fully validated before deployment.

- Ample Inventory Reserves: We maintain large inventory levels to meet your urgent needs, reducing lead times and keeping your operations running smoothly.

- 100% Genuine New Products: We strictly provide original, brand-new items—no refurbished or counterfeit products—ensuring the highest quality and long-term performance.