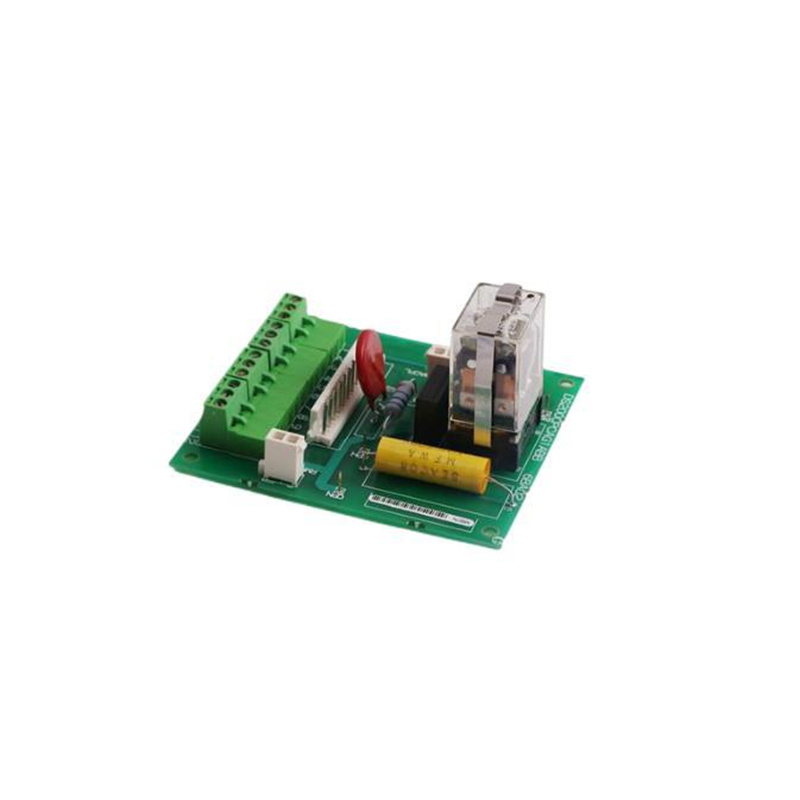

GE DS3800NPMB1A1A processing module

GE DS3800NPMB1A1A

The GE DS3800NPMB1A1A is a network communication and processing module within the General Electric (GE) Mark IV Speedtronic™ series, specifically designed for data exchange and logic processing in gas turbine and steam turbine control systems. Serving as the core communication hub of the Mark IV system, this module coordinates data acquisition from various I/O modules in the rack, executes control algorithms, and communicates with upper-level monitoring systems (such as HMI and DCS) via network interfaces, ensuring the real-time performance and reliability of the entire control architecture.

Core Values of DS3800NPMB1A1A

- High-Speed Data Processing: Leverages a high-performance processor to implement multi-task control logic operations.

- Multi-Protocol Communication: Supports GE proprietary protocols (e.g., SRTP) and standard protocols (e.g., Modbus TCP).

- System Redundancy: Configurable as a redundant pair to enhance system availability.

Product Specifications

- Product Model: DS3800NPMB1A1A

- Manufacturer: General Electric (GE)

- Product Type: Network Processing and Communication Module

- Compatible System: GE Mark IV Speedtronic™

- Processor Architecture: 32-bit RISC Processor

- Memory Capacity: 16MB RAM (typical)

- Communication Interfaces: 2× RS-485 (Modbus RTU), 1× Ethernet (10Mbps)

- Supported Protocols: GE SRTP, Modbus RTU/TCP

- Backplane Bandwidth: 10Mbps (Mark IV backplane bus)

- Operating Temperature Range: 0°C to +60°C (32°F to +140°F)

- Protection Class: IP20 (must be installed in a control cabinet)

- Installation Method: Vertically inserted into the Mark IV rack, occupying 1 slot

- Power Requirement: +5V DC (powered by the Mark IV backplane)

- Power Consumption: ≤8W (typical)

Structure and Composition

- Central Processing Unit (CPU): A 32-bit RISC processor that executes control logic and communication protocol stacks.

- Memory Unit: Static RAM for storing runtime data, and Flash for storing firmware and configurations.

- Communication Interface Circuitry: Isolation-designed RS-485 interfaces (supporting Modbus RTU master/slave modes) and an Ethernet controller (10Base-T, supporting the GE SRTP protocol).

- Backplane Interface: A high-speed connector that interacts with the Mark IV backplane to access data from I/O modules.

- Status Indicators: LEDs for displaying power (PWR), operation (RUN), and communication (COM) status.

- Metal Enclosure: Provides EMI shielding and mechanical protection, complying with industrial anti-vibration standards.

Application Fields

- Power Generation Industry: Acts as the main controller for gas turbines/steam turbines, coordinating combustion control and speed regulation.

- Oil and Gas Industry: Serves as the core of control systems in compressor stations, integrating local I/O and remote communication.

- Industrial Drives: Enables comprehensive protection and control for large pump sets.

Installation and Maintenance

Installation Key Points

- Perform operations with power off (or confirm the system supports hot swapping), and wear an anti-static wristband.

- Insert the module into the designated slot of the Mark IV rack (usually the dedicated processor slot).

- Set a terminal resistor (120Ω, for end nodes) for the RS-485 bus.

Maintenance Recommendations

- Regularly check the module’s operating status (via LEDs or the ToolboxST diagnostic tool).

- Back up firmware and configuration parameters (to prevent accidental loss).

- Clean the module’s heat dissipation surface to ensure efficient heat dissipation.

————————————————————————————————————-

If you would like to learn more about our products and services, please feel free to contact us at any time!

- Sales Manager : Jinny

- Email : sales5@xrjdcs.com

- Whatsapp/Mobile:+86 15359273791

Global renowned brand cooperation

ABB 丨 GE 丨Allen Bradley 丨 Honeywell 丨 Emerson 丨 Bently Nevada 丨 Westinghouse

Triconex 丨 Foxboro 丨 ICS Triplex 丨 Hima 丨 Schneider 丨 Yokogawa 丨 Woodward

—————————————————————————————

Industrial Automation: Components & Tailored Solutions

- Distributed Control Systems (DCS) – for large-scale process control scenarios

- Programmable Logic Controllers (PLC) – core for discrete manufacturing automation

- MOTOROLA MVME Industrial Modules – reliable support for legacy industrial setups

- Anybus Industrial Communication Converters – enabling seamless cross-protocol communication

- Remote I/O Modules (RTU) – ideal for distributed field data acquisition

- Industrial PCs (IPC) – rugged computing solutions for harsh industrial environments

- Industrial Low-Frequency Screens – high-stability displays for 24/7 operation

- HMI SCSI Interfaces (50, 68, 80 Pin) – ensuring compatible HMI connectivity

- AnyBus Gateways – bridging gaps between different industrial networks

What Makes Us Your Trusted Partner?

Global-Class Inventory Readiness

- We hold one of the industry’s most comprehensive inventories of automation spares, covering PLCs, DCS, drives, HMIs, and more. No matter your equipment’s brand or age, we ensure quick access to the parts you need – no long waits.

Engineer-Led Technical Support

- Our team isn’t just sales-focused – it’s made up of engineers with hands-on experience in industrial control systems. From troubleshooting hardware malfunctions to guiding software upgrades, we provide actionable, on-site-level support remotely.

Needs-Driven Custom Services

- We don’t just supply parts – we solve problems. Beyond standard spares, we offer customized services like old equipment repair, system retrofitting (to extend equipment lifespan), and on-site technical training for your team.

Global Reach, Local Response

- Our worldwide service network means we can coordinate sourcing and delivery from regional hubs, cutting down lead times. Wherever your facility is, you get the same fast, reliable service as local suppliers.

Obsolete Parts Specialists

- For discontinued or end-of-life components – a pain point for many factories – we have dedicated sourcing channels. We track hard-to-find parts globally, ensuring your legacy systems keep running.

Service That Puts You First

- Every interaction is guided by one goal: your operational efficiency. We prioritize transparency (no hidden costs), on-time delivery, and post-sales follow-up – making sure your needs are met at every step.