Welcome to our websites!

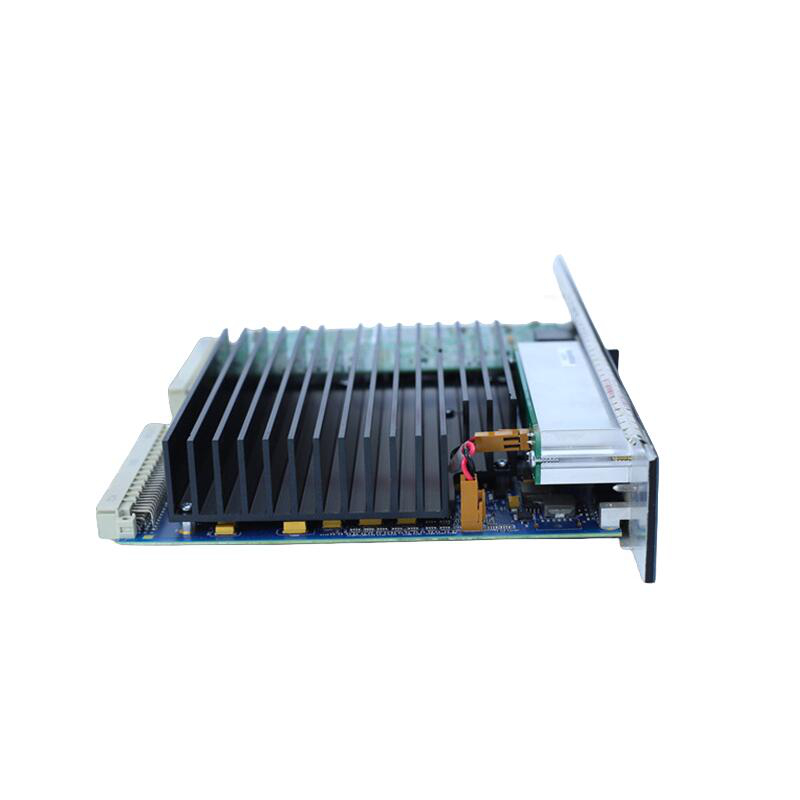

GE DS3827CSN06A Control Interface Board

GE DS3827CSN06A

1. Product Overview

The GE DS3827CSN06A is a core component of the highly acclaimed Mark IV Speedtronic series gas turbine and steam turbine control systems under General Electric (GE). Specifically, it is a high-performance communication servo control interface board. This module plays a crucial role in the automated control cabinet: it is specially designed to receive commands from the upper-level controller and drive key actuators related to turbine operation (e.g., hydraulic servo valves), thereby achieving precise and high-speed control over parameters such as fuel valve position and inlet guide vane (IGV) opening.

The outstanding performance of the GE DS3827CSN06A module ensures that the entire turbine control system can achieve rapid response, high-precision regulation, and stable and reliable operation. It is one of the core hardware components that guarantee efficient and safe power generation of generator sets. Its design fully reflects GE’s profound technical accumulation in the field of heavy industry drive and control. Tailored to cope with harsh industrial environments, it features extremely high reliability and durability.

2. Product Specifications

- Product Model: DS3827CSN06A

- Manufacturer: GE (General Electric)

- Product Type: Communication Servo Control Interface Board

- Applicable System: Mark IV Speedtronic Turbine Control System

- Main Function: Servo Drive and Position Control Interface

- Connector Type: Multi-pin Ribbon Cable Connector

- Installation Method: Fixed to the chassis backplane via screws

- Operating Temperature: 0°C – 65°C (in operation); -40°C – 85°C (not in operation)

- Operating Humidity: 5% – 95% (non-condensing)

- Design Standard: Suitable for industrial-grade environments

3. Structure and Composition

The GE DS3827CSN06A module adopts a classic industrial-grade printed circuit board (PCB) design, with multiple dedicated integrated circuits (ICs), resistor-capacitor networks, and power drive components onboard. Its core structure includes a multi-pin connector for data and power connection with the Mark IV system VME backplane—this serves as the physical foundation for high-speed communication between the module and the main controller.

The board integrates precise signal conditioning circuits, which process command signals from the controller and convert them into power signals capable of driving high-current servo valves. Meanwhile, the module typically includes feedback signal processing circuits to receive and process signals from position sensors such as linear variable differential transformers (LVDT), forming a closed-loop control system. LED status indicators are integrated on the board to display the module’s power status and communication activity in real time, facilitating quick diagnosis by technicians.

4. Key Features and Advantages

- High-Precision Drive: The GE DS3827CSN06A integrates precise signal amplification and conditioning circuits, enabling highly stable and accurate control output. This ensures optimal precision in controlling turbine actuators, thereby optimizing combustion efficiency and improving overall power generation efficiency.

- Superior Reliability: Manufactured and designed in compliance with GE’s strict industrial standards, the components selected for this module can withstand temperature fluctuations, electrical noise, and mechanical vibrations commonly encountered in power plant environments. It boasts an extremely long mean time between failures (MTBF), minimizing unplanned downtime.

- Seamless System Integration: As a native component of the Mark IV Speedtronic system, the DS3827CSN06A can work perfectly in synergy with other control modules, I/O modules, and power supply modules in the same series. Plug-and-play integration is achievable without complex configuration, greatly simplifying the system assembly and maintenance processes.

- Comprehensive Diagnostic Functions: Through onboard LED indicators and system software, the module provides clear status and fault information. This allows maintenance personnel to quickly locate issues, shorten troubleshooting time, and improve equipment maintainability.

5. Application Fields

The GE DS3827CSN06A module is almost exclusively used in the energy power generation sector that employs GE Mark IV control systems. Its main application scenarios include large-scale natural gas combined-cycle power plants, simple-cycle gas turbine power stations, and large-scale steam turbine power stations.

In this field, it is directly used to control the servo mechanism that drives the gas turbine fuel valve—by precisely adjusting the fuel supply, it controls the turbine’s speed and power output. Additionally, it is used to control the actuator of the inlet guide vane (IGV), optimizing intake flow and temperature to protect turbine blades and improve operating efficiency under partial load conditions. It is an indispensable key control component for ensuring that generator sets can quickly respond to grid load changes and achieve safe, stable, and efficient operation.

6. Installation and Maintenance

6.1 Pre-Installation Preparation

Before installing the GE DS3827CSN06A module, ensure that the entire Mark IV control system is completely powered off, and implement the Lockout-Tagout (LOTO) procedure to ensure personnel safety. Prepare an anti-static wristband and conductive foam pad to prevent damage to electrostatically sensitive components during operation. Check that the pins of the target chassis slot are clean and free from bending, and confirm that the firmware version of the new module is compatible with the existing system.

6.2 Maintenance Recommendations

Conduct regular inspections of the control system, and observe whether the status indicators on the DS3827CSN06A module display normally. Keep the internal environment of the control cabinet clean, perform regular dust removal, and ensure that the cooling fans operate properly to prevent module aging due to overheating.

In the event of a module failure, it is recommended to replace the entire module with a spare part of the same model, and send the faulty unit to a professional institution for repair or identification. On-site component-level maintenance operations are not recommended.

————————————————————————————————————-

If you would like to learn more about our products and services, please feel free to contact us at any time!

- Sales Manager : Jinny

- Email : sales5@xrjdcs.com

- Whatsapp/Mobile:+86 15359273791

Global renowned brand cooperation

ABB 丨 GE 丨Allen Bradley 丨 Honeywell 丨 Emerson 丨 Bently Nevada 丨 Westinghouse

Triconex 丨 Foxboro 丨 ICS Triplex 丨 Hima 丨 Schneider 丨 Yokogawa 丨 Woodward

—————————————————————————————

Your Go-To Partner for Tailored Automation Solutions

We stand as your reliable ally in the realm of automation, bringing forth expertise honed through years of dedicated focus on advancing automation technologies. Our service portfolio spans the full spectrum of automation needs, encompassing core components like PLCs (Programmable Logic Controllers), DCS (Distributed Control Systems), and frequency converters—along with end-to-end support from design to maintenance.

No matter the industry challenge: whether you’re seeking precise control over intricate processes in the petrochemical sector, or aiming to cut energy consumption for motors in the power industry, we don’t just offer “solutions”—we craft strategies tailored to your unique operational goals, workflow nuances, and long-term efficiency targets.

What sets our products apart? They’re engineered for unwavering stability and exceptional durability, having undergone rigorous quality assessments to meet global industry standards. Every product we deliver is a testament to our commitment to reliability.

The Unique Advantages of Partnering With Us

- Premium-Grade Quality Assurance: Beyond basic compliance, our products are built to exceed industry benchmarks—ensuring consistent performance even in harsh or high-demand operational environments.

- Reliable On-Time Delivery: Leveraging a streamlined supply chain and proactive project management, we minimize lead times and keep your projects on track, even for time-sensitive requirements.

- Extensive Range of Authentic Branded Parts: We source components exclusively from leading, trusted brands in the automation industry—guaranteeing compatibility, performance, and long service life.

- Seasoned Professionals + Advanced Testing Infrastructure: Our team comprises experts with decades of hands-on experience in automation, while our state-of-the-art testing facilities validate every solution’s functionality, safety, and efficiency before deployment.

- Robust Inventory Reserves: We maintain a large-scale inventory of key components and finished products, enabling rapid response to urgent orders and preventing costly project downtime.

- 100% Genuine New Products Only: We never compromise on quality—all items we provide are 100% original, brand-new, and free from refurbished or counterfeit parts, ensuring optimal performance and peace of mind.

Write your message here and send it to us