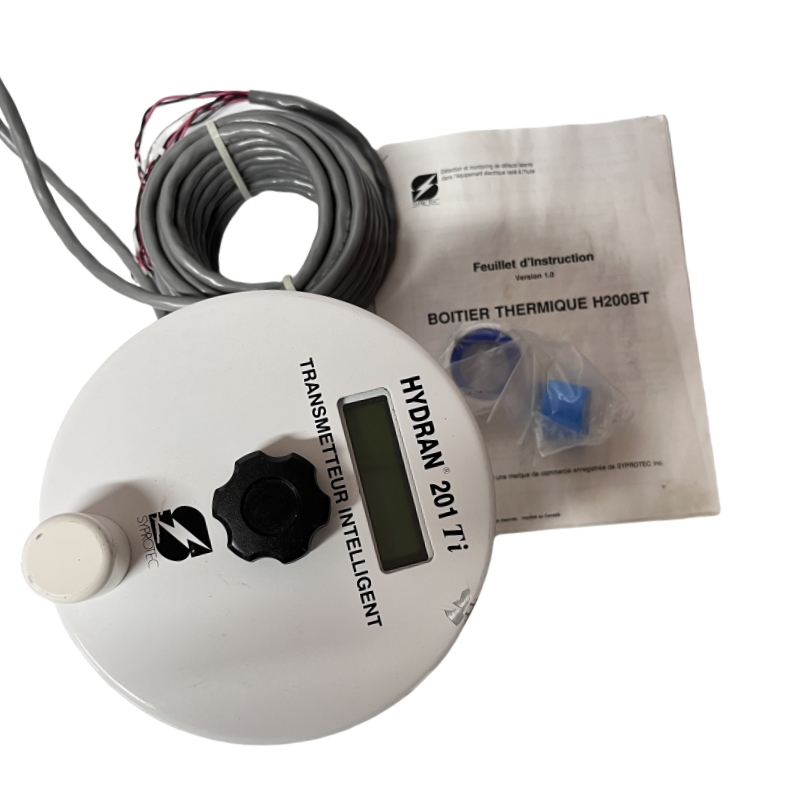

GE H201TI Key Equipment

GE H201TI

Overview

Parameters

Input Voltage

- 100-240V AC (for DGA monitor)

- 18-36V DC (for Hall effect sensor version)

- 220V AC (for power adapter version)

Output Power

- 200W (DGA monitor)

- 0.75-4kW (mechatronics module)

Operating Temperature Range

- -40°C to +85°C (DGA monitor)

- -20°C to +55°C (electromechanical module)

Dimensions and Weight

- 200mm x 100mm x 50mm (DGA monitor)

- 120 x 80 x 60 mm (electromechanical module)

- Weight: 1.5-2.5 kg (depending on version)

Other Parameters

- Accuracy: ±10% of reading ±25 ppm (DGA monitoring)

- Response time: <1 μs (Hall sensor)

- Communication protocols: Modbus, RS-485, USB

Product Features

High Precision and Real-Time Performance

- Adopts fuel cell sensor technology, with 100% response to hydrogen, and a monitoring range of 0-2000 ppm.

- Real-time display of gas concentrations, supporting historical data recording (up to 1 year).

Modularity and Compatibility

- Supports industrial protocols such as Modbus, Profibus, and Ethernet, enabling seamless integration with SCADA systems.

- Provides digital input/output, analog signal interfaces, and alarm contacts (high gas level, system failure).

Durability and Maintenance

- No pump or additional pipeline design, directly installed on the transformer oil valve, reducing maintenance complexity.

- Self-check function and remote diagnostic capability, reducing the need for on-site calibration.

Safety and Reliability

- Protection class IP55 (some versions), insulation class B/F.

- Compliant with NEMA and IEC standards, suitable for harsh industrial environments.

Structure and Composition

Core Components

- HYDRAN® sensor: Fuel cell-type composite gas sensor, monitoring hydrogen, carbon monoxide, acetylene, and ethylene.

- Thermal regulation system: Ensures stable operation of the sensor within a wide temperature range.

- Microprocessor electric transmitter: Processes data and supports Modbus/RS-485 communication.

Interfaces and Functions

- Local display: Backlit LCD screen displays gas readings in real-time.

- Remote communication: RS-485 isolated port and USB interface, supporting data transmission and system configuration.

- Alarm system: 3 dry contact relay alarms, supporting sound-light/remote alarms.

Application Fields

Power Systems

- Transformer health monitoring (power generation, transmission, and distribution networks).

- Transformer early warning in wind farms and solar photovoltaic systems.

Industrial Automation

- Motor control and protection (overload, undervoltage, short-circuit protection).

- Real-time control of industrial robots and servo drives.

Commercial and Residential

- Power management of household appliances and building automation systems.

- Stable power supply for medical equipment and security monitoring.

Installation and Maintenance

Installation Process

- Permanently installed on the transformer oil valve, connected via a brass adapter, no additional pumps or pipelines required.

- Supports DIN rail installation (electromechanical module).

Maintenance Points

- Regular inspection: Confirm sensor cleanliness and terminal contact.

- Data recording: Use local storage to analyze historical trends and assist in fault diagnosis.

- Sensor replacement: It is recommended to replace the sensor every 2-3 years to maintain accuracy.

Notes

- Avoid on-site calibration and rely on self-check functions.

- Environmental temperature and humidity should be within the range of -40°C to +85°C.

————————————————————————————————————-

If you would like to learn more about our products and services, please feel free to contact us at any time!

- Sales Manager : Jinny

- Email : sales5@xrjdcs.com

- Whatsapp/Mobile:+86 15359273791

Global renowned brand cooperation

ABB 丨 GE 丨Allen Bradley 丨 Honeywell 丨 Emerson 丨 Bently Nevada 丨 Westinghouse

Triconex 丨 Foxboro 丨 ICS Triplex 丨 Hima 丨 Schneider 丨 Yokogawa 丨 Woodward

—————————————————————————————

We are a customer-centric company offering comprehensive industrial control products and services. We not only provide a complete range of industrial control equipment, but also offer professional technical support, after-sales service, and system integration services. Our mission is to eliminate all worries for customers, allowing them to focus on their core businesses.

-

We always provide combined shipping discounts for multiple items. The final combined shipping rate will depend on the weight and size of the items.

-

We will ship the goods within 1-3 working days upon receipt of payment.

-

Our daily cutoff time for express delivery shipments is 6:00 PM.

- International buyers: Import duties, taxes, and fees are not included in the product price or shipping costs. These expenses shall be borne by the buyer.