Welcome to our websites!

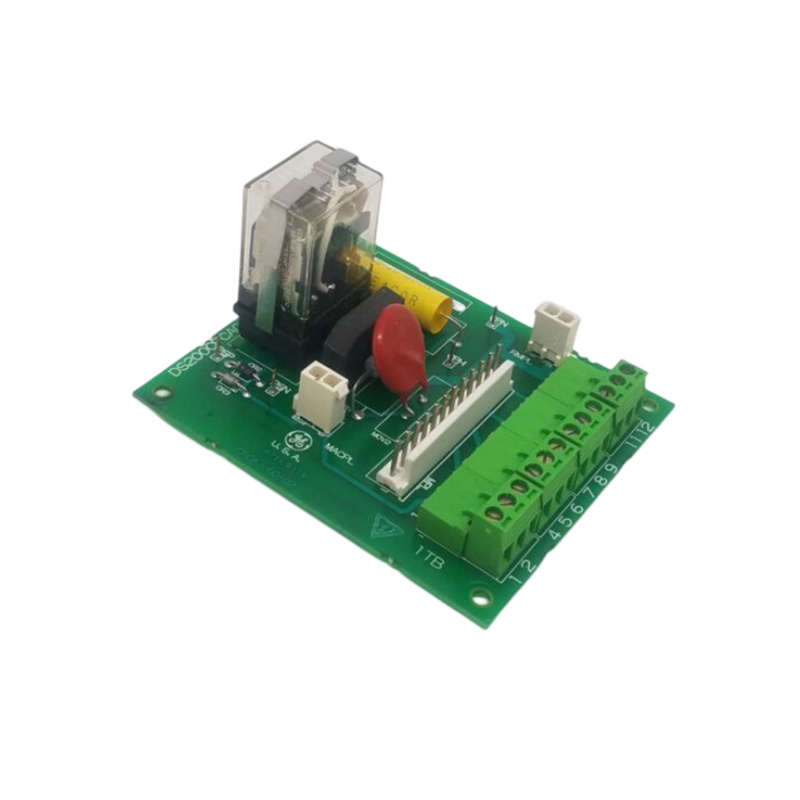

GE IC600CB903 Universal Backboard

GE IC600CB903

1. Product Overview

GE IC600CB903 is a high-performance 20-slot universal backplane designed by General Electric (GE) for its RX3i Series Programmable Automation Controller (PAC) systems. As a fundamental and critical component in automated control systems, this backplane serves as the physical connection carrier and data communication backbone for all other I/O modules, CPU processors, power supply modules, and communication modules.

GE IC600CB903 provides 20 module slots, offering sufficient expansion capability for building large-scale and complex control systems. It can accommodate a wide range of digital modules, analog modules, and special-function modules to meet various demanding application requirements. Its core value lies in providing stable mechanical support, reliable power distribution, and high-speed data exchange channels for all inserted modules—ensuring coordinated, stable, and efficient operation of all components in the PAC system. It is thus the cornerstone for constructing large-scale, high-performance, and high-reliability automated control platforms.

2. Product Specifications

- Product Model: IC600CB903

- Manufacturer: GE (General Electric)

- Product Type: 20-slot universal backplane

- Product Series: RX3i PACSystems

- Compatible Platform: Supports all CPUs and I/O modules of the RX3i Series

- Number of Slots: 20

- Bus Type: PCI Bus (for high-speed communication between CPU and modules)

- Power Interfaces: 2 (supports dual-power redundancy configuration)

- Installation Method: Standard DIN rail mounting or panel screw mounting

- Physical Dimensions: See detailed drawings; determined by chassis configuration

- Operating Temperature: 0°C to 60°C

3. Structure and Composition

The GE IC600CB903 backplane is essentially a multi-layer Printed Circuit Board (PCB) with a precise and robust structural design. Twenty high-reliability module slot connectors are neatly arranged on the board; the pin definition of each connector strictly complies with PCI Bus standards and GE’s power supply specifications to ensure electrical compatibility with various modules.

A complex power distribution network is integrated inside the backplane, which safely and stably delivers multiple voltages (e.g., +5V, +3.3V, ±24V) from the power supply module to each slot. Meanwhile, high-speed PCI Bus traces are laid on the board, forming a “highway” for data exchange between all modules and the central processor.

Sturdy power connector sockets are usually located at both ends or sides of the backplane for connecting to the system power supply. The backplane may also include status indicator lights and mounting holes for fixing to racks or rails.

4. Key Features and Advantages

Excellent Expandability and Flexibility

The GE IC600CB903 backplane offers up to 20 standard slots, providing unparalleled I/O point capacity and function expansion capabilities for users to build large-scale control systems. Users can flexibly configure various types of I/O modules, communication modules, and special-function modules according to project requirements to easily handle complex control tasks. When expansion is needed in the future, only additional modules are required—no need to replace the backplane.

High-Speed System Performance

This backplane adopts a PCI Bus architecture, providing extremely high data transmission bandwidth between the CPU and each I/O module. This ensures that even when processing large volumes of I/O data and control logic, the system maintains fast response speeds and excellent scanning performance, meeting the strict requirements of real-time control applications.

High-Reliability Design

The backplane uses high-quality materials and industrial-grade manufacturing processes to ensure long-term mechanical strength and reliable electrical connections. It supports dual-power module redundancy configuration (when used with a redundant CPU kit): if one power supply fails, the other can take over seamlessly to ensure continuous system operation, greatly improving the fault tolerance and availability of the overall solution.

Seamless System Integration

As a standard component of the RX3i platform, the IC600CB903 achieves plug-and-play compatibility with all modules in GE’s PACSystems series. This simplifies system design, installation, and maintenance processes, reduces the complexity of engineering integration, and ensures the stability and consistency of the entire system’s operation.

5. Application Fields

Due to its strong expansion capabilities, the GE IC600CB903 is mainly used in medium-to-large automated projects that require handling large numbers of I/O points and complex control logic. Its typical application fields include:

- Distributed Control Systems (DCS) in large water treatment plants and sewage treatment plants;

- Complete vehicle production line control in the automotive manufacturing industry;

- Process control for continuous casting and rolling in the metallurgical industry;

- Material handling and warehouse logistics systems (ASRS);

- Crushing and conveying control in the mining industry.

In these scenarios, the IC600CB903 backplane acts as the core framework of the system, enabling centralized installation of a large number of discrete modules, analog modules, motion control modules, and network communication modules. It realizes data collection for thousands of measurement points and precise control of hundreds of devices, building a centralized, efficient, and reliable control center.

6. Installation and Maintenance

Pre-Installation Preparation

Before installing the GE IC600CB903 backplane, first confirm the cabinet size and installation location to ensure sufficient space and consider heat dissipation requirements. Prepare appropriate installation tools, such as screwdrivers and DIN rails. Before operation, be sure to disconnect all power supplies and take anti-static measures to avoid electrostatic damage to the precision connectors on the backplane.

Maintenance Recommendations

Daily maintenance mainly involves keeping the backplane and slots clean: regularly use a soft brush or hair dryer to remove accumulated dust, preventing poor contact or heat dissipation issues caused by dust. When the system is powered off, check whether the connectors on the backplane have physical damage or signs of corrosion.

When inserting or removing modules, always ensure the power supply is turned off and operate vertically with uniform force to avoid damaging the pins. The backplane itself has no user-serviceable parts; if a fault occurs, it must be replaced entirely by professional personnel.

————————————————————————————————————-

If you would like to learn more about our products and services, please feel free to contact us at any time!

- Sales Manager : Jinny

- Email : sales5@xrjdcs.com

- Whatsapp/Mobile:+86 15359273791

Global renowned brand cooperation

ABB 丨 GE 丨Allen Bradley 丨 Honeywell 丨 Emerson 丨 Bently Nevada 丨 Westinghouse

Triconex 丨 Foxboro 丨 ICS Triplex 丨 Hima 丨 Schneider 丨 Yokogawa 丨 Woodward

—————————————————————————————

Your Go-To Partner for Tailored Automation Solutions

We stand as your reliable ally in the realm of automation, bringing forth expertise honed through years of dedicated focus on advancing automation technologies. Our service portfolio spans the full spectrum of automation needs, encompassing core components like PLCs (Programmable Logic Controllers), DCS (Distributed Control Systems), and frequency converters—along with end-to-end support from design to maintenance.

No matter the industry challenge: whether you’re seeking precise control over intricate processes in the petrochemical sector, or aiming to cut energy consumption for motors in the power industry, we don’t just offer “solutions”—we craft strategies tailored to your unique operational goals, workflow nuances, and long-term efficiency targets.

What sets our products apart? They’re engineered for unwavering stability and exceptional durability, having undergone rigorous quality assessments to meet global industry standards. Every product we deliver is a testament to our commitment to reliability.

The Unique Advantages of Partnering With Us

- Premium-Grade Quality Assurance: Beyond basic compliance, our products are built to exceed industry benchmarks—ensuring consistent performance even in harsh or high-demand operational environments.

- Reliable On-Time Delivery: Leveraging a streamlined supply chain and proactive project management, we minimize lead times and keep your projects on track, even for time-sensitive requirements.

- Extensive Range of Authentic Branded Parts: We source components exclusively from leading, trusted brands in the automation industry—guaranteeing compatibility, performance, and long service life.

- Seasoned Professionals + Advanced Testing Infrastructure: Our team comprises experts with decades of hands-on experience in automation, while our state-of-the-art testing facilities validate every solution’s functionality, safety, and efficiency before deployment.

- Robust Inventory Reserves: We maintain a large-scale inventory of key components and finished products, enabling rapid response to urgent orders and preventing costly project downtime.

- 100% Genuine New Products Only: We never compromise on quality—all items we provide are 100% original, brand-new, and free from refurbished or counterfeit parts, ensuring optimal performance and peace of mind.

Write your message here and send it to us