GE SD-98762 servo drive

GE SD-98762

GE SD-98762 is a high-performance servo drive in the Industrial Automation Series of General Electric (GE). Designed specifically for precision motion control applications, it is suitable for machine tools, robots, packaging equipment, and automated production lines. This drive adopts an advanced vector control algorithm to achieve precise speed, position, and torque control of servo motors. It supports high-resolution feedback devices and multiple communication protocols, ensuring fast system response and stable operation.

Core Values of SD-98762

- High-Precision Motion Control: Supports 24-bit absolute encoders to achieve micron-level positioning accuracy.

- Multi-Function Integration: Built-in PLC function (optional) to simplify system architecture.

- Flexible Communication: Compatible with mainstream industrial protocols such as EtherCAT, Modbus TCP/IP, and Profibus DP.

Product Specifications

- Product Model: SD-98762

- Manufacturer: General Electric (GE)

- Product Type: Servo Drive

- Rated Output Power: 2.0kW

- Rated Output Current: 9.0A (continuous) / 13.5A (peak)

- Input Power Supply: Three-phase 200-240V AC (±10%), 50/60Hz

- Control Modes: Position control, speed control, torque control

- Feedback Interface: Incremental encoder, absolute encoder (multi-turn/single-turn), resolver

- Communication Protocols: EtherCAT, Modbus TCP/IP, Profibus DP, CANopen

- Control Accuracy: ±1 pulse (position control)

- Response Bandwidth: 2.0kHz (speed loop)

- Operating Temperature Range: 0°C to +55°C (32°F to +131°F)

- Protection Class: IP20 (must be installed in an electrical control cabinet)

- Installation Method: DIN Rail mounting or screw fixing

- Certification Standards: CE, UL, cUL

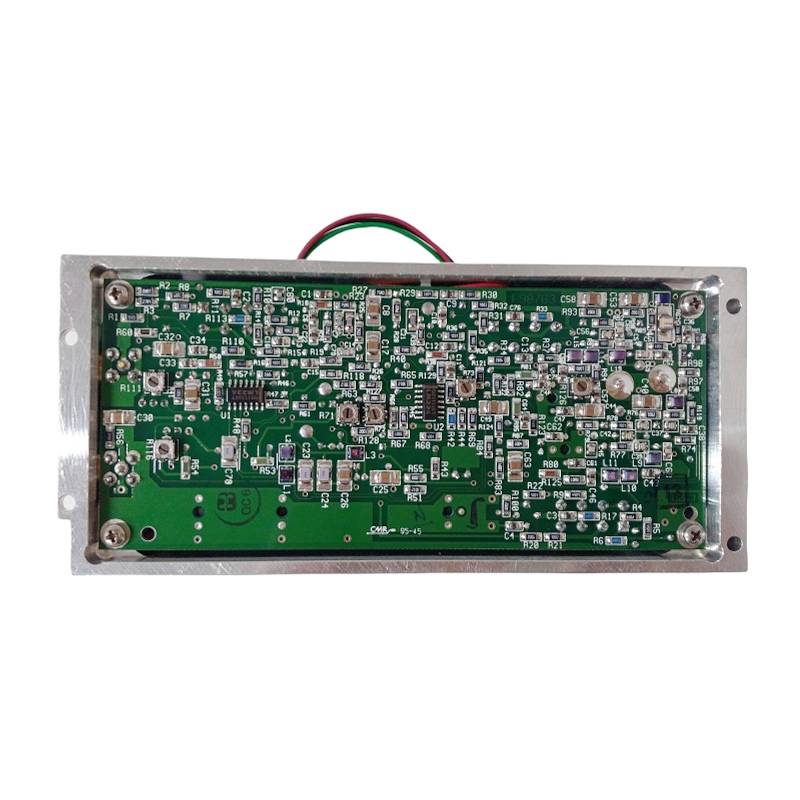

Structure and Composition

-

Power Module:

Equipped with an IGBT inverter circuit to generate three-phase PWM waveforms for driving servo motors. -

Control Unit:

Features a high-performance DSP processor that runs real-time control algorithms (e.g., PID, feedforward control). -

Communication Interface Board:

Integrates EtherCAT, RS-485, and CANopen interfaces to support multi-protocol communication. -

Heat Dissipation System:

Consists of aluminum heat sinks + forced air cooling (built-in fan) to ensure stable operation in high-temperature environments. -

Status Indicator Lights:

LED lights display power status, operation status, and fault codes (e.g., overcurrent, overvoltage). -

Housing:

Made of metal material, providing EMI shielding and mechanical protection.

Key Features and Advantages

1. High-Precision Motion Control

- Micron-level interpolation function, suitable for precision machining (e.g., laser cutting, semiconductor packaging).

- Adaptive vibration suppression algorithm to reduce the impact of mechanical resonance on positioning accuracy.

2. Intelligent Debugging and Diagnosis

- Automatically optimizes servo parameters (e.g., rigidity, bandwidth) via GE Motion Builder software.

- Real-time monitors current, temperature, and load rate to warn of potential faults.

3. Seamless System Integration

- Natively supports EtherCAT high-speed bus, enabling multi-axis synchronous control (≤1ms cycle).

- Optional built-in PLC function for executing simple logic tasks (e.g., cam curve planning).

4. Industrial-Grade Reliability

- Overload capacity of 150% (sustained for 3 seconds) to handle instantaneous load impacts.

- Complies with the IEC 61800-3 standard, featuring strong anti-electromagnetic interference capability.

Application Fields

- Machine Tool Industry: Drive for CNC machine tool feed axes (e.g., X/Y/Z axes of milling machines).

- Industrial Robots: Servo control for joints of 6-axis robots.

- Packaging Equipment: Synchronous positioning control for high-speed labeling machines.

- Electronic Manufacturing: Precision pick-and-place of components in SMT placement machines.

In automated packaging lines, SD-98762 drives the GE AFM300 servo motor, synchronizing with the upper-level PLC via EtherCAT to achieve high-speed and accurate labeling of 120 times per minute.

Related Products

- GE AFM300: High-performance servo motor, used in conjunction with SD-98762.

- GE Motion Builder: Debugging software, available for free download.

- SD-98763: 3.0kW version, serving as a power expansion option.

Installation and Maintenance

Installation Key Points

- Reserve a heat dissipation space of ≥100mm in the electrical control cabinet, with ambient temperature ≤55°C.

- Separate power lines (U/V/W) from encoder lines, with a minimum spacing of 30cm.

- Perform auto-tuning (to identify motor parameters) during the first power-on.

Maintenance Recommendations

- Clean the heat dissipation fan filter every six months (shorten the cycle in dusty environments).

- Regularly back up parameters (via USB or upper-level software).

————————————————————————————————————-

If you would like to learn more about our products and services, please feel free to contact us at any time!

- Sales Manager : Jinny

- Email : sales5@xrjdcs.com

- Whatsapp/Mobile:+86 15359273791

Global renowned brand cooperation

ABB 丨 GE 丨Allen Bradley 丨 Honeywell 丨 Emerson 丨 Bently Nevada 丨 Westinghouse

Triconex 丨 Foxboro 丨 ICS Triplex 丨 Hima 丨 Schneider 丨 Yokogawa 丨 Woodward

—————————————————————————————

Industrial Automation: Components & Tailored Solutions

- Distributed Control Systems (DCS) – for large-scale process control scenarios

- Programmable Logic Controllers (PLC) – core for discrete manufacturing automation

- MOTOROLA MVME Industrial Modules – reliable support for legacy industrial setups

- Anybus Industrial Communication Converters – enabling seamless cross-protocol communication

- Remote I/O Modules (RTU) – ideal for distributed field data acquisition

- Industrial PCs (IPC) – rugged computing solutions for harsh industrial environments

- Industrial Low-Frequency Screens – high-stability displays for 24/7 operation

- HMI SCSI Interfaces (50, 68, 80 Pin) – ensuring compatible HMI connectivity

- AnyBus Gateways – bridging gaps between different industrial networks

What Makes Us Your Trusted Partner?

Global-Class Inventory Readiness

- We hold one of the industry’s most comprehensive inventories of automation spares, covering PLCs, DCS, drives, HMIs, and more. No matter your equipment’s brand or age, we ensure quick access to the parts you need – no long waits.

Engineer-Led Technical Support

- Our team isn’t just sales-focused – it’s made up of engineers with hands-on experience in industrial control systems. From troubleshooting hardware malfunctions to guiding software upgrades, we provide actionable, on-site-level support remotely.

Needs-Driven Custom Services

- We don’t just supply parts – we solve problems. Beyond standard spares, we offer customized services like old equipment repair, system retrofitting (to extend equipment lifespan), and on-site technical training for your team.

Global Reach, Local Response

- Our worldwide service network means we can coordinate sourcing and delivery from regional hubs, cutting down lead times. Wherever your facility is, you get the same fast, reliable service as local suppliers.

Obsolete Parts Specialists

- For discontinued or end-of-life components – a pain point for many factories – we have dedicated sourcing channels. We track hard-to-find parts globally, ensuring your legacy systems keep running.

Service That Puts You First

- Every interaction is guided by one goal: your operational efficiency. We prioritize transparency (no hidden costs), on-time delivery, and post-sales follow-up – making sure your needs are met at every step.