GE TGT-S000-1-1 Sensor Module

GE TGT-S000-1-1

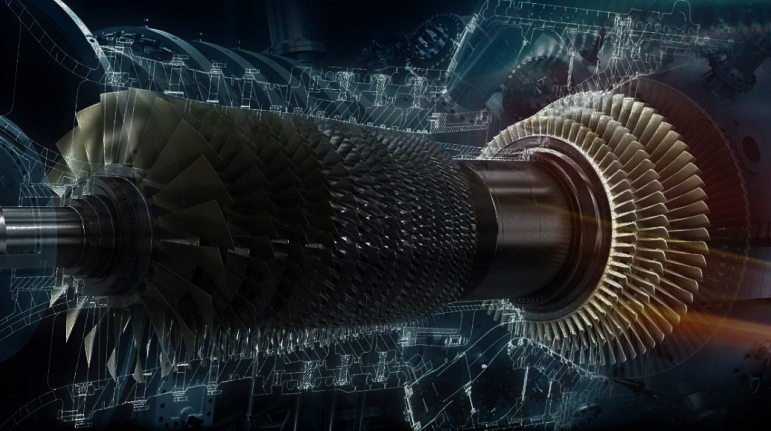

The GE TGT-S000-1-1 is a turbine governor transducer module under the TGT (Turbine Governor Transducer) series of General Electric (GE). It is specifically designed for speed monitoring and speed control of gas turbines, steam turbines, and hydro turbines. By measuring the rotor speed with high precision and transmitting signals to the speed control system, this module ensures the unit operates stably within the set speed range and prevents overspeed or underspeed faults.

- Real-time speed detection: Based on magnetoelectric or photoelectric sensing technology, with an accuracy of ±0.1% FS.

- Signal conditioning and output: Provides 4-20mA, pulse frequency, or Modbus signals, compatible with mainstream governors (e.g., Woodward 505).

- Fault self-diagnosis: Built-in health monitoring circuit, capable of detecting issues such as sensor disconnection and signal loss.

Product Parameters

- Product Model: TGT-S000-1-1

- Manufacturer: General Electric (GE)

- Product Type: Turbine Speed Sensor Module

- Measurement Range: 0-10,000 RPM (customizable)

- Output Signal: 4-20mA / Pulse Frequency (e.g., 60Hz) / Modbus RTU

- Accuracy: ±0.1% FS

- Response Time: ≤10ms

- Power Supply Voltage: 24V DC (±10%)

- Protection Level: IP67 (sensor probe) / IP20 (electronic module)

- Operating Temperature Range: -30°C to +85°C (-22°F to +185°F)

- Probe Type: Magnetoelectric (default) / Photoelectric (optional)

- Mechanical Interface: M12×1 threaded mounting / Flange mounting (optional)

- Certification Standard: ATEX / IECEx (explosion-proof optional)

Structure and Composition

- Sensing Probe:

- Magnetoelectric type: Triggers pulses through gears or grooves, no external power supply required.

- Photoelectric type: Suitable for clean environments with higher resolution.

- Signal Conditioning Module:

- Converts pulse signals into standard outputs (4-20mA/Modbus).

- Built-in filter circuit to suppress vibration interference.

- Connection Cable:

- Shielded twisted pair, with customizable length (5 meters by default).

- Status Indicator Light:

- LED displays power supply, signal status, and fault codes.

Key Features and Advantages

-

High-reliability speed monitoring:

- With an accuracy of ±0.1%, it meets the requirements of the ISO 7919 vibration standard for steam turbines.

- Resistant to oil pollution and dust (magnetoelectric type), suitable for the harsh environment of gas turbines.

-

Flexible output configuration:

- Provides both 4-20mA (analog) and pulse signals (digital) simultaneously, compatible with old and new control systems.

- Modbus RTU supports remote parameter configuration (e.g., range, filtering time).

-

Plug-and-play installation:

- Fixed via M12 thread or flange; the probe gap can be fine-tuned with gaskets (0.5-1.0mm recommended).

- Modular electronic unit, supporting DIN Rail or panel mounting.

-

Adaptability to harsh environments:

- Wide temperature operation from -30°C to +85°C, with vibration resistance of 5g @ 1kHz.

- The explosion-proof version (TGT-S000-1-1EX) has passed ATEX Zone 2 certification.

Related Products

- TGT-S000-1-1EX: Explosion-proof version, used in hazardous areas.

- IS200STCCH2A: GE Mark VIe speed card, used in conjunction with the module.

- Bently Nevada 3300: Vibration monitoring system, with complementary functions.

Installation and Maintenance

Installation Steps

- Align the probe with the gear (number of teeth ≥ 60), and adjust the gap to 0.8mm (feeler gauge verification required).

- Ground one end of the shielded cable (on the control cabinet side) to avoid signal interference.

- After power-on, confirm the signal status through the LED (green = normal, red = fault).

Maintenance Recommendations

- Check the probe gap every 6 months (vibration may cause loosening).

- Regularly clean the window of the photoelectric probe (if selected) with alcohol.

————————————————————————————————————-

If you would like to learn more about our products and services, please feel free to contact us at any time!

- Sales Manager : Jinny

- Email : sales5@xrjdcs.com

- Whatsapp/Mobile:+86 15359273791

Global renowned brand cooperation

ABB 丨 GE 丨Allen Bradley 丨 Honeywell 丨 Emerson 丨 Bently Nevada 丨 Westinghouse

Triconex 丨 Foxboro 丨 ICS Triplex 丨 Hima 丨 Schneider 丨 Yokogawa 丨 Woodward

—————————————————————————————

Why Choose Us?

- World-Renowned Brands:

A-B, ABB, GE, TRICONEX, BENTLY, EMERSON, etc. - High Quality; 24/7 Online Service

- Favorable Prices; Short Delivery Time

- Large Inventory; Factory Supply

- Global Shipping: Via DHL, UPS, FedEx and TNT

After-Sales Service Guarantee

- We provide comprehensive after-sales service guarantees, including product fault repair, technical support, and operation training. This ensures customers receive timely and professional assistance during use, keeping your industrial control products in optimal condition at all times.

- Reliable Product Quality: We cooperate with well-known domestic and foreign industrial control brand manufacturers. Our products feature reliable quality, stable performance, and low failure rates, which can meet all your needs.

- Professional Technical Support: We have an experienced technical team capable of providing you with professional technical support and services.

- Preferential Prices: We have established good cooperative relationships with suppliers, enabling us to offer you competitive prices.

- Thoughtful Service: We provide comprehensive pre-sales, in-sales, and after-sales services, allowing you to have no worries.