Welcome to our websites!

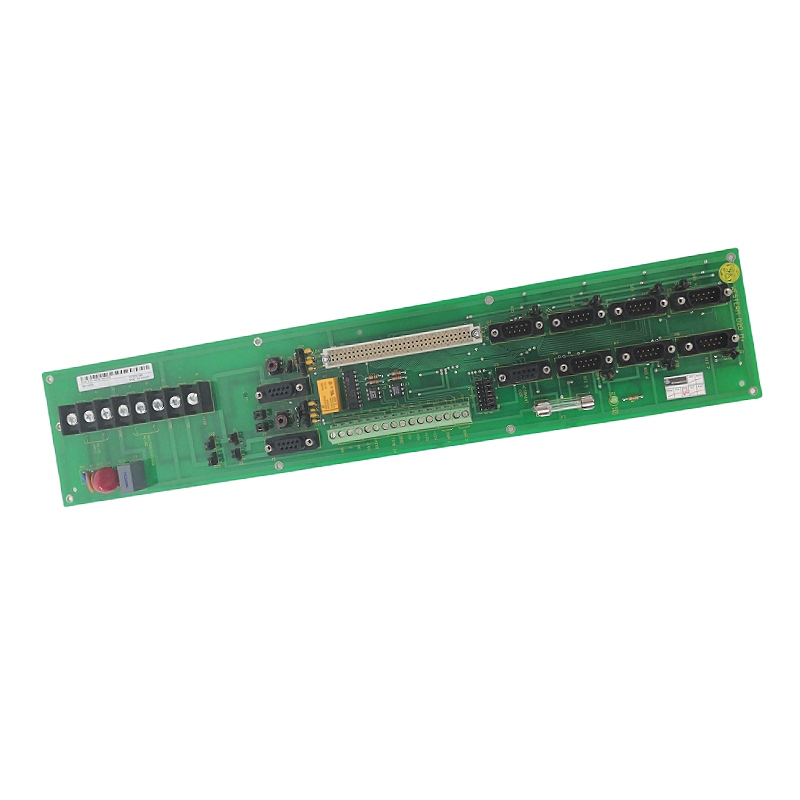

GE WESTEM D20 M++CNC System

GE WESTEM D20 M++

1. Overview

The GE WESTERM D20 M++ is a high-performance numerical control (NC) system, specifically designed for machining equipment such as CNC milling machines, lathes, and machining centers. It delivers excellent performance and stability, with its core function being to control the motion axes and spindles of machine tools—making it suitable for high-precision machining tasks.

2. Parameters

Input Module Parameters

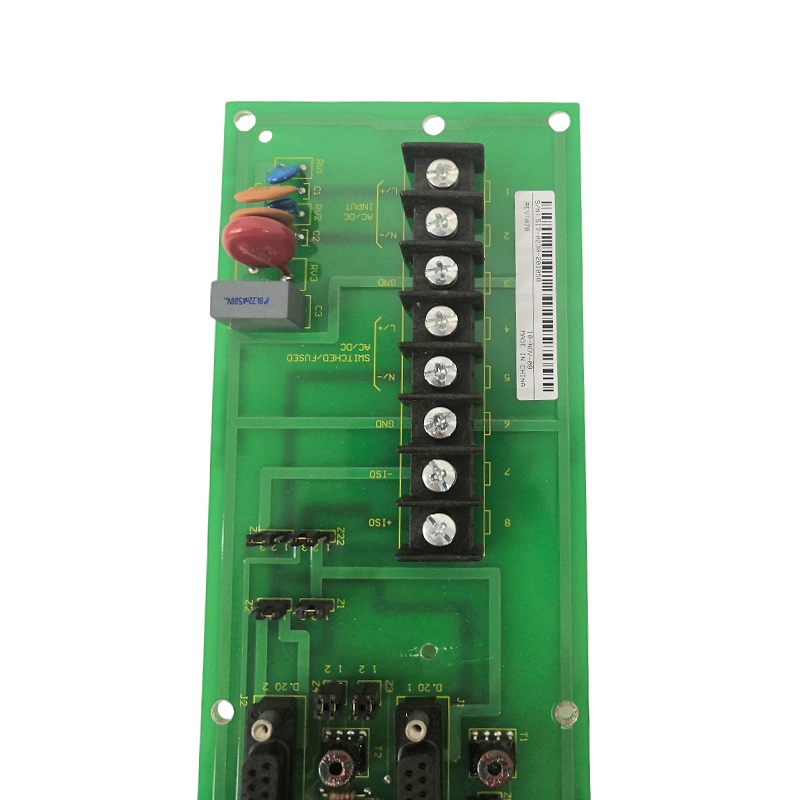

- Number of input channels: 8 (analog input, supporting voltage or current input).

- Resolution: 16-bit; Accuracy: ±0.1% FS; Response time: ≤2ms.

- Operating temperature: -40°C to 85°C; Protection class: IP67.

- Other modules: For example, the status input module (WESDAC D20S) supports 64 digital inputs, and is equipped with surge protection and pulse protection.

3. Product Features

- High Reliability and Industrial-Grade Design: Adopts high-quality components and advanced manufacturing processes, making it suitable for harsh industrial environments.

- Modular Structure: The modular design facilitates installation and maintenance. Examples include detachable modules (WESTERM D20 A and WESDAC D20 A).

- Communication and Interfaces: Supports Ethernet connection, maintenance ports (e.g., DB9 connector), and cascading function.

4. Structure and Composition

- Modular Architecture: Composed of a base (WESTERM D20 A) and a processing module (WESDAC D20 A), connected via a 40-pin connector.

- Terminal Panel: Provides power supply, signal processing, and maintenance interfaces.

5. Application Fields

- Industrial Automation: Widely used in fields such as electric power, metallurgy, petroleum, chemical industry, construction, and water treatment.

- Specific Scenarios: Monitoring and controlling industrial processes, equipment operation, and environmental monitoring.

6. Installation and Maintenance

- Installation: The modular design simplifies installation, supporting on-site wiring and maintenance.

- Maintenance: A maintenance port (e.g., DB9 connector) is provided for diagnosis and communication, supporting on-site repair and parameter adjustment.

————————————————————————————————————-

If you would like to learn more about our products and services, please feel free to contact us at any time!

- Sales Manager : Jinny

- Email : sales5@xrjdcs.com

- Whatsapp/Mobile:+86 15359273791

Global renowned brand cooperation

ABB 丨 GE 丨Allen Bradley 丨 Honeywell 丨 Emerson 丨 Bently Nevada 丨 Westinghouse

Triconex 丨 Foxboro 丨 ICS Triplex 丨 Hima 丨 Schneider 丨 Yokogawa 丨 Woodward

—————————————————————————————

Your Go-To Partner for Tailored Automation Solutions

We stand as your reliable ally in the realm of automation, bringing forth expertise honed through years of dedicated focus on advancing automation technologies. Our service portfolio spans the full spectrum of automation needs, encompassing core components like PLCs (Programmable Logic Controllers), DCS (Distributed Control Systems), and frequency converters—along with end-to-end support from design to maintenance.

No matter the industry challenge: whether you’re seeking precise control over intricate processes in the petrochemical sector, or aiming to cut energy consumption for motors in the power industry, we don’t just offer “solutions”—we craft strategies tailored to your unique operational goals, workflow nuances, and long-term efficiency targets.

What sets our products apart? They’re engineered for unwavering stability and exceptional durability, having undergone rigorous quality assessments to meet global industry standards. Every product we deliver is a testament to our commitment to reliability.

The Unique Advantages of Partnering With Us

- Premium-Grade Quality Assurance: Beyond basic compliance, our products are built to exceed industry benchmarks—ensuring consistent performance even in harsh or high-demand operational environments.

- Reliable On-Time Delivery: Leveraging a streamlined supply chain and proactive project management, we minimize lead times and keep your projects on track, even for time-sensitive requirements.

- Extensive Range of Authentic Branded Parts: We source components exclusively from leading, trusted brands in the automation industry—guaranteeing compatibility, performance, and long service life.

- Seasoned Professionals + Advanced Testing Infrastructure: Our team comprises experts with decades of hands-on experience in automation, while our state-of-the-art testing facilities validate every solution’s functionality, safety, and efficiency before deployment.

- Robust Inventory Reserves: We maintain a large-scale inventory of key components and finished products, enabling rapid response to urgent orders and preventing costly project downtime.

- 100% Genuine New Products Only: We never compromise on quality—all items we provide are 100% original, brand-new, and free from refurbished or counterfeit parts, ensuring optimal performance and peace of mind.

Write your message here and send it to us