Welcome to our websites!

ABB PFSA140 3BSE006503R1 Industrial Control Unit

ABB PFSA140 3BSE006503R1

1. Overview

The ABB PFSA140 3BSE006503R1 is a modular industrial control unit launched by ABB, mainly designed for scenarios such as reel power supply, tension control, and safety logic. Featuring high reliability and a compact structure, it is compatible with a variety of ABB automation systems, delivering stable performance for industrial control tasks.

2. Key Specifications

- Operating Voltage: 24 V DC

- Rated Power: Approximately 1 kW, with an output frequency of 2 kHz

- Current: 2 × 2 × 1.2 A (constant current)

- Input/Output Signal Range: 0–10 V, 0–20 mA

- Operating Temperature: -40 °C to +70 °C

- Protection Class: IP20 (inside cabinet)/IP54/IP65

- Communication Interfaces: PROFIBUS, PROFINET, Ethernet/IP, RS-485, etc.

3. Product Features

- Modular Design: Facilitates on-site installation, expansion, and maintenance, and occupies only 1 I/O slot, optimizing cabinet space utilization.

- High-Precision Tension Control: Ideal for packaging, textile, papermaking, and other industries, enabling accurate adjustment of material tension to ensure production quality.

- Multi-Protocol Compatibility: Supports various fieldbuses and Ethernet protocols, allowing seamless integration into existing industrial automation systems with minimal adaptation effort.

- Robust and Durable: Complies with international certifications such as CE, UL, and IEC, and can operate stably in harsh industrial environments with dust, vibration, and temperature fluctuations.

- Safety Rating: Meets SIL 3 safety requirements and provides reliable safety relay functions, safeguarding personnel and equipment in critical control scenarios.

4. Structure and Components

- Core processor module (PFSA140)

- 24 V DC power supply unit

- Analog/digital input/output terminal block

- Communication interface board (supporting PROFIBUS, Ethernet, etc.)

- Status indicator lights (for operation/fault monitoring)

5. Application Fields

- Reel power supply and drive systems

- High-performance tension control (for packaging, textile, paper, and metal processing industries)

- Safety control and implementation of SIL 3-level safety logic

- Industrial automation network nodes for fieldbus or Ethernet communication

6. Installation and Maintenance

- Installation Method: Can be mounted on a rail-type rack (TK807A/B) compatible with standard 19-inch cabinets, or directly installed in the control room for flexible deployment.

- Wiring: Follow the wiring diagrams for power supply, I/O, and communication interfaces, and implement protective measures corresponding to the product’s protection class to prevent electrical faults.

- Commissioning: Configure parameters and conduct function tests via ABB Control Builder or the corresponding PLC programming software to ensure the unit operates as designed.

- Maintenance: The modular structure enables quick replacement of faulty components. The indicator lights provide clear operation/fault status prompts; it is recommended to regularly inspect power and communication connections to maintain system stability.

————————————————————————————————————-

If you would like to learn more about our products and services, please feel free to contact us at any time!

- Sales Manager : Jinny

- Email : sales5@xrjdcs.com

- Whatsapp/Mobile:+86 15359273791

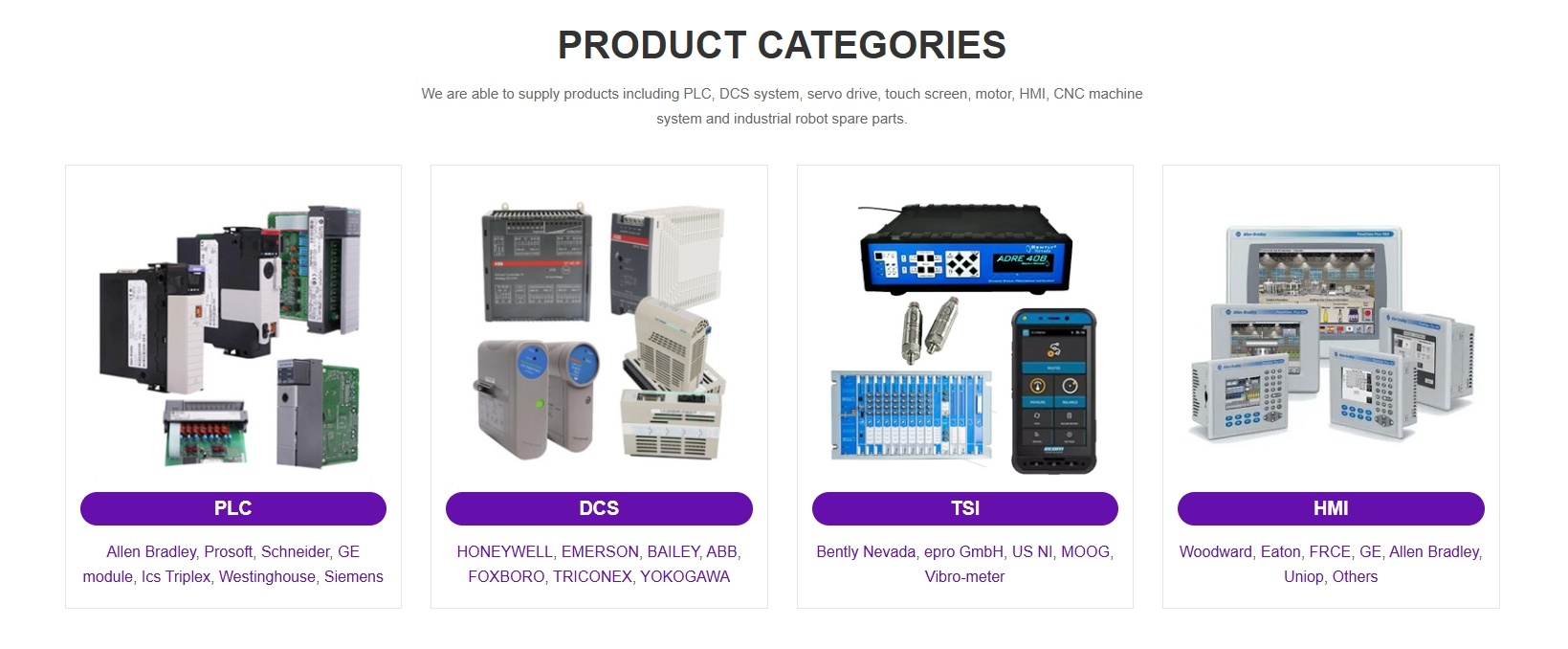

Global renowned brand cooperation

ABB 丨 GE 丨Allen Bradley 丨 Honeywell 丨 Emerson 丨 Bently Nevada 丨 Westinghouse

Triconex 丨 Foxboro 丨 ICS Triplex 丨 Hima 丨 Schneider 丨 Yokogawa 丨 Woodward

—————————————————————————————

Our Value

- Boost Production Efficiency: With automation transformation, we realize the automation and intelligence of production processes, significantly improving production efficiency and reducing production costs.

- Improve Product Quality: Precise automated control ensures stable product quality and reduces the rate of defective products.

- Enhance Market Competitiveness: Advanced automation technology helps enterprises stand out in the fierce market competition.

- Achieve Green Production: Automation systems can optimize energy utilization, reduce environmental pollution, and realize green production.

Our Services

- System Integration: We provide full-process services from system design, equipment selection, installation and commissioning to after-sales service.

- Spare Parts Supply: We have a rich inventory of spare parts and can quickly provide original genuine spare parts to ensure the normal operation of equipment.

- Technical Training: We offer professional technical training for customers to help them quickly master the operation and maintenance of equipment.

Write your message here and send it to us