Schneider AEG MM-PM10-200 Operating Panel

Schneider AEG MM-PM10-200

The MM-PM10-200 is a PanelMate Plus series HMI (Human-Machine Interface) launched by Schneider Electric (formerly AEG). As a 10-inch (approx. 254 mm) touch screen operation panel, it is specially designed for on-site monitoring and operation of Modicon PLC systems. Adopting a modular design, this panel can be used with Schneider’s Power-Module, IO-Module and other accessories to achieve compact and reliable on-site control.

Key Technical Specifications

- Display Size: 10-inch (254 mm) TFT color touch screen

- Resolution: 800 × 480 pixels (WVGA)

- Supply Voltage: 18 – 30 V DC, Power Consumption: approx. 11 W

- Operating Temperature: -20 °C – +60 °C, Optional Protection Class: IP20 / IP54

- Communication Interfaces: Multiple fieldbuses including Modbus RTU, Profibus-DP, Ethernet/IP and CANopen

- Optional Function Modules: Alarm light, keyboard, extended I/O, wireless module, etc.

- Certifications: CE, UL, CSA and other international safety certifications

Product Features

- Modular Structure: The panel body, backplane and base are fixed by bolts or welding, enabling quick on-site assembly and maintenance.

- High Reliability: Equipped with industrial-grade components, it supports redundant power supply and hot standby, ideal for critical process procedures.

- Multi-protocol Compatibility: Built-in multiple fieldbus protocols, realizing seamless connection with Modicon PLC, Power-Module and IO-Module directly.

- User-friendly Interface: Supports graphical editing, script programming, alarm history recording and other functions for intuitive operation.

- Environmental Adaptability: Dustproof and waterproof design (IP54) with wide operating temperature range, suitable for workshops, on-site sites, outdoor and other environments.

Structure & Components

- Display Unit: 10-inch TFT touch screen with built-in backlight

- Control Mainboard: Integrated with CPU, storage and communication chips, responsible for screen rendering and protocol processing

- Power Module: Accepts 18-30 V DC input and provides internal voltage stabilization

- Cabinet & Base: Metal or high-strength plastic cabinet; the base can be fixed by bolts or welding for easy cabinet installation

- Optional Extension Modules: Alarm light, keyboard, wireless communication, additional I/O interfaces, etc.

Typical Application Fields

- Automated Production Lines: Monitor PLC status, set process parameters and display alarm information

- Process Control: On-site operation and data acquisition in chemical, food, pharmaceutical and other industries

- Energy & Power: Operation monitoring and remote diagnosis of distribution stations and substations

- Building Automation: Centralized management of air conditioning, lighting and security systems

- Transportation Facilities: Status display of public facilities such as subways, light rails and parking lots

Installation & Maintenance Notes

- Pre-installation Check: Confirm the supply voltage is within 18-30 V DC range, and check the grounding of the cabinet or on-site environment

- Fixing Method: The base can be fixed by 4×M16 bolts or welding; for cabinet multi-screen connection, use 8×M8 hexagon socket bolts for connection

- Wiring Standards: Comply with IEC 60204-1 electrical safety standards; separate signal wires from power wires to avoid interference

- Software Configuration: Use Schneider’s Vijeo Designer or EcoStruxure Operator Terminal software for screen design and parameter setting

- Regular Inspection: Check touch screen response, interface connection and power stabilization every 6 months; inspect the dustproof and waterproof sealing of IP54-rated cabinets

- Fault Diagnosis: The panel has a self-test function; when a fault occurs, locate the problem through built-in diagnostic logs or remote PLC alarm information

If you would like to learn more about our products and services, please feel free to contact us at any time!

- Sales Manager : Jinny

- Email : sales5@xrjdcs.com

- Whatsapp/Mobile:+86 15359273791

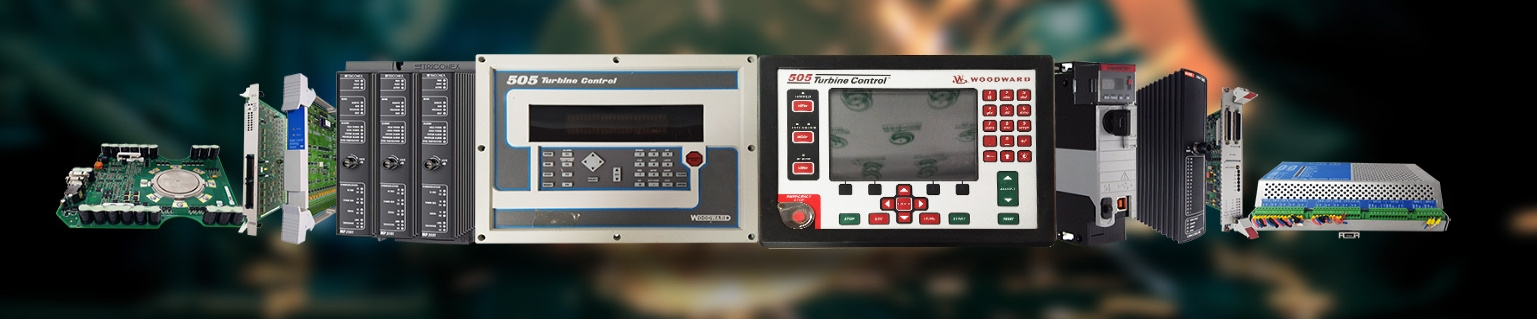

Global renowned brand cooperation

ABB 丨 GE 丨Allen Bradley 丨 Honeywell 丨 Emerson 丨 Bently Nevada 丨 Westinghouse

Triconex 丨 Foxboro 丨 ICS Triplex 丨 Hima 丨 Schneider 丨 Yokogawa 丨 Woodward

—————————————————————————————

1.Reduce Maintenance Costs: We help you cut down equipment maintenance expenses by providing high-quality spare parts and professional services.

2.Minimize Downtime: Fast spare parts supply reduces equipment downtime and boosts overall production efficiency.

3.Extend Equipment Lifespan: Using genuine or compatible premium spare parts effectively prolongs your equipment’s service life.

4.One-Stop Global Supply of PLC Spare Parts: Whatever brand or model of PLC spare parts you need, we deliver fast and accurate solutions.

5.Professional Team & Technical Support: Our team of experienced engineers provides you with professional technical support and reliable repair services.

6.Genuine-Quality Products at Competitive Prices: All our PLC spare parts are genuine or compatible alternatives, ensuring top-tier quality while offering more favorable pricing.

7.Fast Response & Global Shipping: With a sound logistics system, we respond to your needs quickly and deliver spare parts to you in a timely manner.

Our Advantageous Services