Woodward 8273-465 Industrial Control Module

Woodward 8273-465

The Woodward 8273-465 is an industrial control module launched by Woodward. It is mainly used for speed and load control of engines, gas turbines, and other high-speed rotating machinery. This model belongs to Woodward’s Load-Sharing / Governor series. It features high-precision speed closed-loop control and multi-point load distribution functions, enabling synchronous adjustment among multiple devices to improve the overall efficiency and reliability of the system.

Main Specifications

- Power Supply Voltage: 24 V DC (12 V DC optional)

- Output Signal: 0-10 V DC, 4-20 mA, PWM (configurable)

- Communication Interface: RS-232, RS-422, Modbus RTU, CANopen, Ethernet (TCP/IP)

- Operating Temperature Range: -40 °C ~ +85 °C (meeting industrial-grade protection standards)

- Dimensions: Approximately 120 mm × 80 mm × 30 mm (compact modular design)

- Weight: Approximately 0.6 kg (lightweight for easy installation)

- Accuracy: Speed control error ≤ ±0.25% (full scale)

- Response Time: < 10 ms (fast closed-loop)

Product Features

- High-Precision Closed-Loop Control: Adopts an advanced digital signal processing chip to achieve precise adjustment of speed and load.

- Multi-Protocol Compatibility: Supports multiple fieldbuses, facilitating seamless integration with upper-level systems (DCS, PLC, SCADA).

- Modular Structure: Uses plug-in terminal blocks and detachable I/O cards for quick maintenance and replacement.

- Self-Diagnosis and Fault Alarm: Built-in diagnostic function that can real-time monitor internal status and report fault codes through the communication port.

- Wide Temperature Adaptability: Complies with IP56 protection rating, suitable for harsh industrial environments.

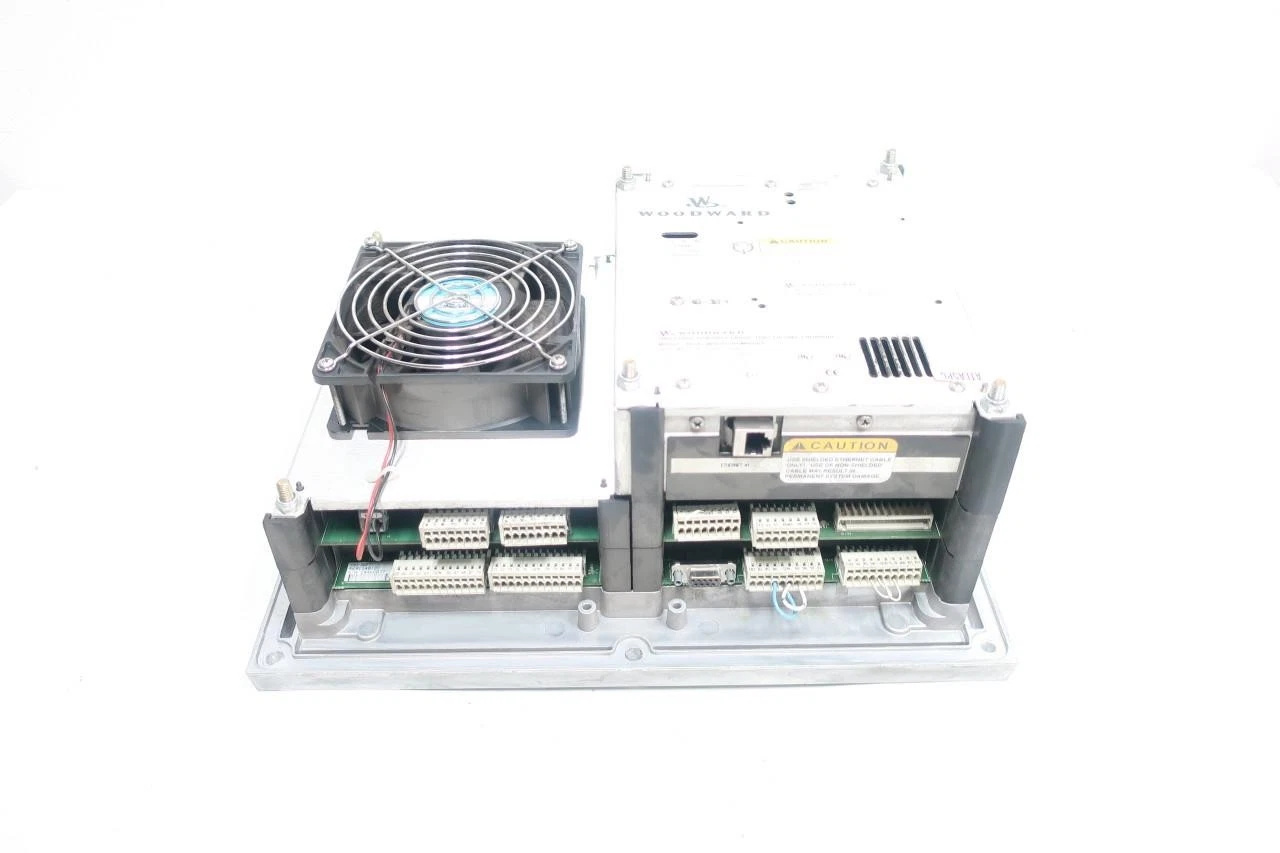

Structure and Composition

- Main Control Unit: Digital processor and memory, responsible for algorithm execution and parameter storage.

- Power Module: Internal DC-DC converter, providing regulated power supply.

- I/O Interface Board: Analog input/output, digital I/O, and communication ports.

- Heat Dissipation Device: Aluminum alloy heat sink and fan (optional), ensuring thermal stability during long-term operation.

- Mounting Bracket: Standard DIN rail or panel mounting accessories.

Typical Application Fields

- Speed/load control of gas turbines and steam turbines in power plants

- Synchronous speed regulation of marine main engines and auxiliary engines

- Load distribution of petrochemical compressors and pump stations

- Aero-engine ground test systems

- Other industrial scenarios requiring precise speed regulation of high-speed rotating machinery

Installation and Maintenance Points

Installation

- Fix using DIN rail or panel, ensure the module is placed horizontally. Follow the polarity marks when connecting power and signal lines.

Wiring

- Use shielded cables for connecting analog/digital I/O. Communication cables (RS-485, CAN) should maintain the minimum bending radius to avoid electromagnetic interference.

Parameter Configuration

- Perform on-site parameter setting through the configuration software provided by Woodward (such as ControlStation) and save to the internal EEPROM of the module.

Commissioning

- Conduct a self-test after first power-on to confirm all I/O are normal. Then perform closed-loop commissioning to verify speed response and load distribution accuracy.

Daily Maintenance

- Regularly check if the heat sink and fan are dusty, and clean the air vents. Perform firmware upgrade every 6 months to obtain the latest control algorithms and security patches.

Fault Handling

- The module’s self-diagnosis will generate fault codes. Refer to the fault table in the technical manual for troubleshooting. If necessary, replace the I/O card or the entire unit for on-site maintenance.

————————————————————————————————————-

If you would like to learn more about our products and services, please feel free to contact us at any time!

- Sales Manager : Jinny

- Email : sales5@xrjdcs.com

- Whatsapp/Mobile:+86 15359273791

Global renowned brand cooperation

ABB 丨 GE 丨Allen Bradley 丨 Honeywell 丨 Emerson 丨 Bently Nevada 丨 Westinghouse

Triconex 丨 Foxboro 丨 ICS Triplex 丨 Hima 丨 Schneider 丨 Yokogawa 丨 Woodward

—————————————————————————————

Why Xiamen Xingruijia Stands Out for DCS Spare Parts Procurement

1. Deep Industry Expertise

- Specialized Focus: We’ve concentrated on DCS spare parts sales for years, building profound knowledge and hands-on experience across leading brands like ABB, FOXBORO, TOSHIBA, ALSTOM, and HITACHI. This specialization lets us quickly grasp your specific product needs.

- Proactive Technical Support: Our team delivers professional technical assistance to help you troubleshoot equipment malfunctions swiftly—minimizing downtime and keeping your production lines running at peak efficiency.

2. Comprehensive Product Selection

- Wide Brand Coverage: We stock products from a range of globally recognized brands, including ABB and FOXBORO, ensuring we can address the diverse requirements of different industrial setups.

- Extensive Model Availability: No matter the specific model of DCS spare part you need, our inventory covers various specifications, eliminating the hassle of searching for hard-to-find components.

3. Premium Service Experience

- Swift Responsiveness: We prioritize your inquiries and demands, ensuring timely replies and action plans—so you never have to wait long to move forward with your procurement.

- Smooth Logistics Solutions: Our well-established logistics network enables fast and reliable delivery, getting the required spare parts to your doorstep without unnecessary delays.

4. Competitive Pricing Edge

- Direct Sourcing Partnerships: We’ve forged long-term, stable collaborations with original equipment manufacturers (OEMs). This direct link allows us to secure spare parts at favorable rates.

- Efficient Cost Management: Through meticulous cost-control measures, we’re able to pass on the savings to you, ensuring you get high-quality parts at cost-effective prices.

5. Trusted Market Reputation

- Proven Track Record: With years of experience in the DCS spare parts industry, we’ve earned a solid reputation among clients for reliability and professionalism.

- Customer-Centric Approach: We put your needs at the center of everything we do, delivering transparent, trustworthy services that foster long-term partnerships.

Key Reasons to Choose Xiamen Xingruijia

- Simplified Procurement: Our one-stop shopping solution cuts down on the time and effort you spend sourcing spare parts, letting you focus on core operations.

- Guaranteed Quality: All our parts are genuine OEM products, ensuring they’re compatible with your equipment and support consistent, stable performance.

- Cost Savings: Our competitive pricing helps lower your overall maintenance costs, boosting your operational efficiency and bottom line.