Welcome to our websites!

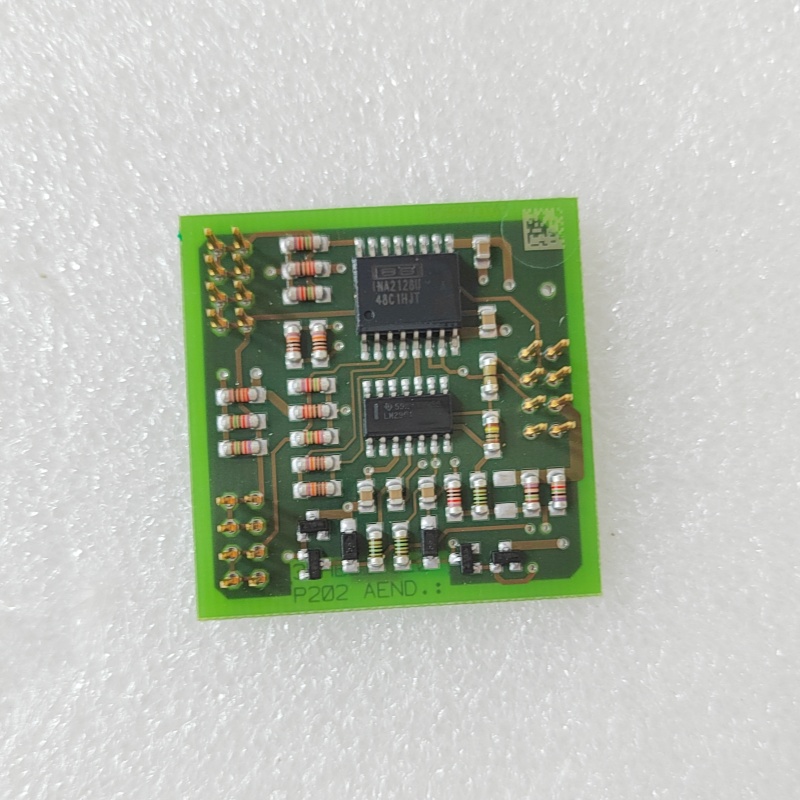

ABB XVC768AE102 3BHB007211R0102 AC Digital Input Module

ABB XVC768AE102 3BHB007211R0102

Overview

The ABB XVC768AE102 (part number 3BHB007211R0102) is a 16-channel AC digital input module designed for the ABB Symphony®Plus DCS system. It is specifically engineered for high-speed acquisition of status signals from field switches, including circuit breakers, disconnectors, pressure switches, and level switches, and supports AC 120 V or AC 230 V signal inputs.

Specifications

| Parameter | Details |

|---|---|

| Model/Part Number | XVC768AE102 / 3BHB007211R0102 |

| Input Type | AC 120 V or AC 230 V (selectable) |

| Number of Channels | 16 |

| Input Voltage Range | AC 85–132 V (120 V mode); AC 198–264 V (230 V mode) |

| Response Time | < 2 ms (typical) |

| Electrical Isolation | 2500 V AC (1 minute) |

| Operating Temperature | 0 °C – 60 °C |

| Storage Temperature | -40 °C – 85 °C |

| Protection Class | IP20 |

| Mounting Method | DIN rail insertion into Symphony® rack, powered by backplane (+5 V, +24 V DC) |

| Certifications | CE, UL, CSA |

Key Features

- 16 independent AC input channels with voltage level configurable via jumpers or software

- 2500 V AC optoelectronic isolation to protect against surges and electrical noise

- Ultra-fast response time (< 2 ms) ideal for high-speed switch status acquisition

- Channel-specific LED indicators (green = closed) for quick on-site status verification

- Built-in diagnostic functions for short-circuit and open-circuit fault detection and reporting

- Hot-swappable design enables zero-downtime maintenance

- Wide operating voltage range for resistance to voltage fluctuations

Structure and Components

- 16 optoelectronically isolated digital input channels

- LED status indicator for each individual channel

- Diagnostic circuit (short-circuit/open-circuit detection)

- Backplane power supply and communication interface

- Rack-mount DIN rail structure for secure installation in Symphony® racks

Application Areas

- Power plants: Monitoring status of steam turbines, auxiliary machinery, and circuit breakers

- Hydropower stations & substations: Interlocking of disconnectors, earthing switches, and circuit breakers

- Petrochemical plants: Status monitoring of valves, compressors, and flare systems

- Water treatment & sewage plants: Control and status tracking of pumps, bar screens, and chemical dosing pumps

- Other scenarios with ABB Symphony® systems: Rail transit and energy management systems for large-scale buildings

Installation and Maintenance

Pre-Installation Preparation

- Ensure the rack is powered off or in hot-swappable mode

- Inspect backplane connectors for cleanliness

- Use wires that meet specifications (1.5 mm² recommended) and refer to the wiring diagram for correct connections

Installation Method

- Insert the module into the Symphony® rack via DIN rail mounting; electrical connection is completed through backplane power supply

Routine Maintenance

- Conduct regular inspections of LED indicators

- Periodically check for loose wiring terminals

- Inspect field contacts for inputs with frequent signal fluctuations

Replacement and Repair

- The module supports hot-swapping; wear an anti-static wristband during operation and ensure the spare module matches the exact model

- Verify functional normalcy via upper-level software after replacement

Diagnostics and Fault Handling

- Leverage the module’s built-in short-circuit/open-circuit diagnostic capabilities to quickly locate faults, which will trigger alarms in the DCS system

————————————————————————————————————-

If you would like to learn more about our products and services, please feel free to contact us at any time!

- Sales Manager : Jinny

- Email : sales5@xrjdcs.com

- Whatsapp/Mobile:+86 15359273791

Global renowned brand cooperation

ABB 丨 GE 丨Allen Bradley 丨 Honeywell 丨 Emerson 丨 Bently Nevada 丨 Westinghouse

Triconex 丨 Foxboro 丨 ICS Triplex 丨 Hima 丨 Schneider 丨 Yokogawa 丨 Woodward

—————————————————————————————

Our Value

- Boost Production Efficiency: With automation transformation, we realize the automation and intelligence of production processes, significantly improving production efficiency and reducing production costs.

- Improve Product Quality: Precise automated control ensures stable product quality and reduces the rate of defective products.

- Enhance Market Competitiveness: Advanced automation technology helps enterprises stand out in the fierce market competition.

- Achieve Green Production: Automation systems can optimize energy utilization, reduce environmental pollution, and realize green production.

Our Services

- System Integration: We provide full-process services from system design, equipment selection, installation and commissioning to after-sales service.

- Spare Parts Supply: We have a rich inventory of spare parts and can quickly provide original genuine spare parts to ensure the normal operation of equipment.

- Technical Training: We offer professional technical training for customers to help them quickly master the operation and maintenance of equipment.

Write your message here and send it to us