Welcome to our websites!

Yaskawa CIMR-F7Z4011 AC Frequency Converter

Yaskawa CIMR-F7Z4011

The CIMR-F7Z4011 is a general-purpose AC inverter belonging to the Yaskawa Varispeed F7 series. It is specifically designed for motor drive applications in industrial automation. This model adopts advanced Current Vector Control technology, enabling high-precision torque and speed control. It is suitable for scenarios that require smooth startup, fast response, and efficient operation.

Key Technical Specifications

- Rated Power: Approximately 4 kW (corresponding to the 4011 model)

- Rated Voltage: 200 V ~ 480 V (single-phase/three-phase)

- Output Frequency Range: 0 ~ 400 Hz (0 ~ 500 Hz optional)

- Control Method: Current Vector Control (FOC), supporting torque, speed, and position closed loops

- I/O Interfaces: Digital I/O, analog signals (0-10 V / 4-20 mA), and fieldbuses (Ethernet/IP, Modbus-TCP, PROFINET, etc.)

- Built-in Functions: PID control, soft start, braking regeneration, fault diagnosis, automatic parameter tuning, and communication protocol stack

- Environmental Requirements: Operating temperature -20 °C ~ +50 °C; protection class IP20 (IP21/IP54 optional)

- Dimensions and Weight: Standard DIN-rail mounting dimensions are approximately 155 mm × 302 mm × 120 mm, with a weight of about 6 kg (refer to the product manual for specific dimensions)

Product Features

- Efficient Vector Control: Utilizes Yaskawa’s self-developed current vector algorithm to achieve low torque fluctuation and high dynamic response.

- Modular Design: The main unit, control panel, radiator, and other components can be replaced independently, facilitating maintenance.

- Multiple Communication Options: Built-in with various industrial Ethernet and fieldbus protocols, enabling easy integration with upper computers, PLCs, and MES systems.

- Powerful Fault Diagnosis: Real-time monitoring of key parameters such as current, voltage, and temperature, providing fault codes and recommended maintenance measures.

- Energy-Saving Braking Regeneration: Feeds back energy to the power grid during deceleration or braking phases, reducing overall energy consumption.

- Flexible Parameter Setting: Parameter configuration, online debugging, and firmware updates can be completed via the built-in web interface or PC software (DriveWizard).

Structure and Composition

- Power Module: Includes power semiconductors (IGBT/SiC), rectifier bridges, filter capacitors, and heat dissipation systems.

- Control Board: Consists of CPU, DSP, memory, analog/digital I/O, and communication interfaces.

- Human-Machine Interface (HMI): Features LCD/LED display screens and button or touch panels for local parameter setting and status display.

- Heat Dissipation Device: Air-cooled or water-cooled radiators to ensure the power module maintains a safe temperature under high loads.

- Terminal Blocks: Multi-channel terminal blocks for power supply, output, control, and communication, complying with IEC standards.

Typical Application Fields

- Packaging Machinery: Synchronous control of high-speed winding and packaging lines.

- Conveying Systems: Variable-frequency speed regulation for belt and chain conveyors.

- Injection Molding and Die Casting: Precise speed and torque control of screw motors.

- Textile Machinery: Tension control of warp and weft threads, and loom drive.

- Pump and Valve Systems: Soft start and energy-saving braking for centrifugal pumps and screw pumps.

- CNC Machine Tools: High-precision speed adjustment of spindles and feed axes.

Installation Points

- Location Selection: Maintain good ventilation, avoid direct sunlight and high-temperature environments, and prevent the intrusion of dust and corrosive gases.

- Fixation: Use DIN-rail or base bolt fixation to ensure the unit is level and minimize vibration transmission.

- Wiring: Strictly follow the wiring diagram for wiring of power supply, output, control, and communication terminals, and use cables that meet the rated current requirements.

- Grounding: Both the main unit and the control unit must be reliably grounded to prevent electromagnetic interference and safety accidents.

- Heat Dissipation: Check the gap between the radiator and the unit to ensure the fan or water-cooling system operates normally.

————————————————————————————————————-

If you would like to learn more about our products and services, please feel free to contact us at any time!

- Sales Manager : Jinny

- Email : sales5@xrjdcs.com

- Whatsapp/Mobile:+86 15359273791

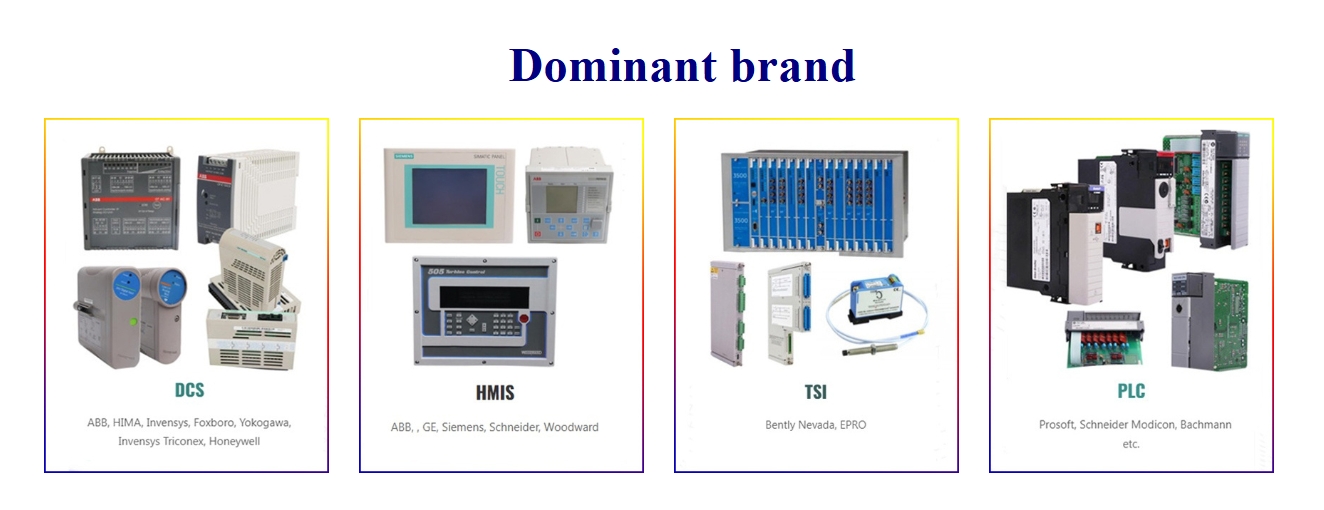

Global renowned brand cooperation

ABB 丨 GE 丨Allen Bradley 丨 Honeywell 丨 Emerson 丨 Bently Nevada 丨 Westinghouse

Triconex 丨 Foxboro 丨 ICS Triplex 丨 Hima 丨 Schneider 丨 Yokogawa 丨 Woodward

—————————————————————————————

Your Reliable Partner for Customized Automation Solutions

As a seasoned expert dedicated to automation technology, we have established ourselves as a trustworthy ally for businesses seeking tailored automation support. Leveraging decades of focused experience in the automation sector, we deliver comprehensive product portfolios and professional services, spanning core components like PLCs, DCS systems, and variable frequency drives (VFDs). Whether you need to optimize complex process control in the petrochemical industry or implement energy-saving solutions for motors in the power sector, our team excels at crafting solutions that align perfectly with your unique operational needs. Our products are recognized for consistent performance and exceptional reliability, all of which have been validated through rigorous international quality certifications.

Why Partnering with Us Adds Value to Your Business

- Superior Quality Assurance: Every product and solution undergoes strict quality checks to meet industry-leading standards, minimizing operational risks for your business.

- On-Time Delivery Commitment: We prioritize efficient supply chain management to ensure your orders are delivered promptly, avoiding delays in your production or project timelines.

- Extensive Range of Branded Components: We stock and supply a wide selection of parts from well-known, reputable brands, guaranteeing compatibility and durability.

- Expert Team & Advanced Testing Facilities: Our team of seasoned professionals, combined with state-of-the-art testing equipment, ensures every solution is fully validated before deployment.

- Ample Inventory Reserves: We maintain large inventory levels to meet your urgent needs, reducing lead times and keeping your operations running smoothly.

- 100% Genuine New Products: We strictly provide original, brand-new items—no refurbished or counterfeit products—ensuring the highest quality and long-term performance.

Write your message here and send it to us