Welcome to our websites!

Yaskawa CIMR-VC4A0023FAA Variable Frequency Drive

Yaskawa CIMR-VC4A0023FAA

The CIMR-VC4A0023FAA is an AC variable frequency drive (VFD) belonging to YASKAWA’s V1000 series, a high-performance Variable Frequency Drive (VFD) product. It is mainly used in industrial automation systems to precisely adjust the speed and torque of motors, achieving energy conservation, smooth starting, and braking functions.

Main Technical Parameters

- Rated Power: 7.5 kW (corresponding to 10 HP constant torque) or 11 kW (corresponding to 15 HP variable torque)

- Rated Current: Approximately 18 A (for 7.5 kW) or 24 A (for 11 kW)

- Input Voltage: Three-phase 380-480 VAC, with a frequency of 50/60 Hz

- Output Frequency Range: 0-400 Hz (enabling high-speed operation)

- Braking Methods: DC injection braking, dynamic braking transistor, no closed-loop braking, no regenerative braking

- Communication Interfaces: Multiple fieldbuses such as Modbus RTU, DeviceNet, EtherNet/IP, and PROFIBUS DP

- Protection Functions: Comprehensive protection against overload, overcurrent, overvoltage, undervoltage, phase sequence error, short circuit, and overheating

- Environmental Adaptability: IP 55 protection rating, operating temperature ranging from -10 °C to +50 °C, suitable for industrial sites

Product Features

- High Energy Efficiency: Adopts the latest IGBT technology and vector control algorithm, with an efficiency of over 96%.

- Multiple Braking Methods: Supports DC injection and dynamic braking to meet the braking needs of different loads.

- Flexible Communication: Compatible with multiple industrial protocols, facilitating integration with systems such as PLC, SCADA, and MES.

- Modular Design: Compact internal structure, convenient for on-site installation, maintenance, and upgrading.

- High Reliability: Equipped with complete self-diagnostic functions and fault records to help quickly locate problems.

Structure and Composition

- Power Module: Responsible for rectification, filtering, and voltage stabilization of the DC link.

- Power Module: An inverter bridge composed of IGBT/IGCT, realizing AC-DC-AC energy conversion.

- Control Unit: A high-speed processor based on DSP/FPGA, executing vector control, braking control, and communication protocols.

- Heat Dissipation System: Air-cooled or water-cooled radiators to ensure temperature control of the power module under high load.

- Human-Machine Interface (HMI): Parameter setting and monitoring can be conducted through a local LCD/keyboard or upper computer software.

- Communication Ports: Provides interfaces such as RS-485, Ethernet, and DeviceNet, supporting fieldbus networks.

Typical Application Fields

- CNC Machine Tools: High-precision servo control to achieve high-speed cutting and stable braking.

- Packaging and Printing: Variable frequency speed regulation improves the flexibility of the production line and reduces energy consumption.

- Textile and Papermaking: Drives high-power motors to meet the demand for continuous operation.

- Conveying and Lifting Systems: Smooth start-stop and soft start protect the mechanical structure.

- Automated Assembly Lines: Drives multi-axis robots and collaborative robots to provide precise motion control.

Installation Key Points

- On-Site Environment: Ensure the installation location has good ventilation to prevent dust and corrosive media from entering.

- Electrical Wiring: Follow the wiring diagram in the product manual, use cables that meet the rated current, and take good grounding and lightning protection measures.

- Heat Dissipation Layout: Maintain a space of at least 150 mm around the front and rear of the radiator; install additional fans or water-cooling systems if necessary.

- Parameter Setting: Before powering on for the first time, configure basic parameters such as motor model, rated power, and braking method through HMI or upper computer software.

- Commissioning and Verification: Conduct no-load operation to check the waveform, temperature, and communication status, then perform load test operation to confirm that the braking and protection functions are normal.

Daily Maintenance Recommendations

- Regular Inspection: Check the power input, wiring tightness, and dust accumulation on the radiator surface every 3-6 months.

- Temperature Monitoring: Pay attention to the operating temperature of the drive during operation; if it exceeds the rated upper limit, check whether the heat dissipation system is blocked.

- Firmware Upgrade: Upgrade according to the latest firmware version released by Yaskawa to obtain better performance and compatibility.

- Fault Diagnosis: Use the built-in self-diagnostic function to read fault codes and quickly locate problems with reference to the manual; replace the power module or IGBT if necessary.

- Spare Parts Management: Keep key components such as power modules, power modules, and cooling fans in stock to shorten maintenance downtime.

————————————————————————————————————-

If you would like to learn more about our products and services, please feel free to contact us at any time!

- Sales Manager : Jinny

- Email : sales5@xrjdcs.com

- Whatsapp/Mobile:+86 15359273791

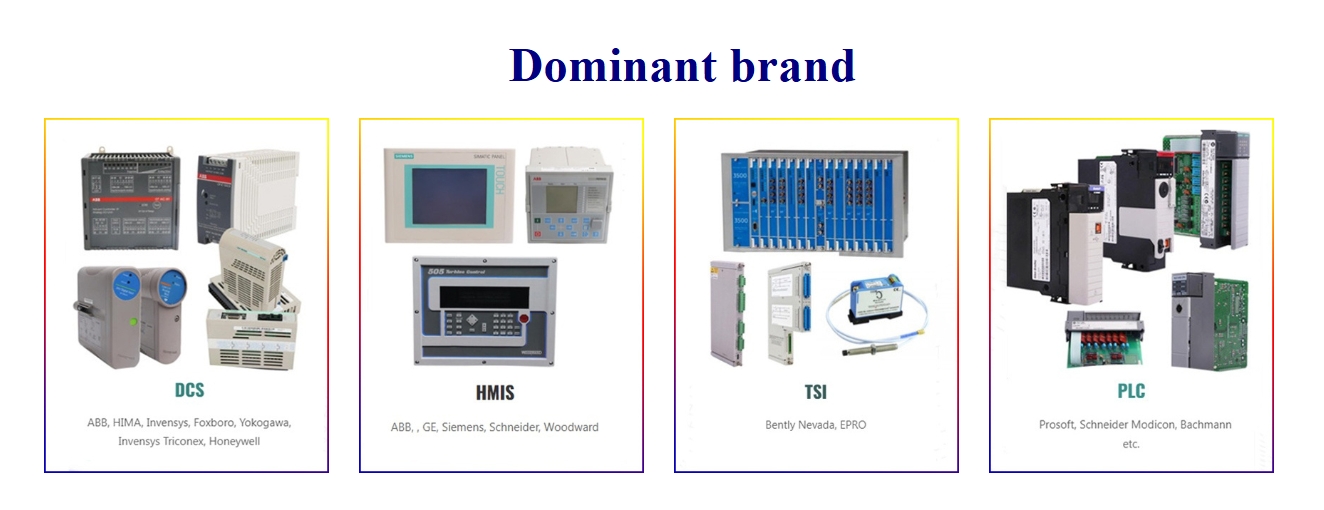

Global renowned brand cooperation

ABB 丨 GE 丨Allen Bradley 丨 Honeywell 丨 Emerson 丨 Bently Nevada 丨 Westinghouse

Triconex 丨 Foxboro 丨 ICS Triplex 丨 Hima 丨 Schneider 丨 Yokogawa 丨 Woodward

—————————————————————————————

Your Reliable Partner for Customized Automation Solutions

As a seasoned expert dedicated to automation technology, we have established ourselves as a trustworthy ally for businesses seeking tailored automation support. Leveraging decades of focused experience in the automation sector, we deliver comprehensive product portfolios and professional services, spanning core components like PLCs, DCS systems, and variable frequency drives (VFDs). Whether you need to optimize complex process control in the petrochemical industry or implement energy-saving solutions for motors in the power sector, our team excels at crafting solutions that align perfectly with your unique operational needs. Our products are recognized for consistent performance and exceptional reliability, all of which have been validated through rigorous international quality certifications.

Why Partnering with Us Adds Value to Your Business

- Superior Quality Assurance: Every product and solution undergoes strict quality checks to meet industry-leading standards, minimizing operational risks for your business.

- On-Time Delivery Commitment: We prioritize efficient supply chain management to ensure your orders are delivered promptly, avoiding delays in your production or project timelines.

- Extensive Range of Branded Components: We stock and supply a wide selection of parts from well-known, reputable brands, guaranteeing compatibility and durability.

- Expert Team & Advanced Testing Facilities: Our team of seasoned professionals, combined with state-of-the-art testing equipment, ensures every solution is fully validated before deployment.

- Ample Inventory Reserves: We maintain large inventory levels to meet your urgent needs, reducing lead times and keeping your operations running smoothly.

- 100% Genuine New Products: We strictly provide original, brand-new items—no refurbished or counterfeit products—ensuring the highest quality and long-term performance.

Write your message here and send it to us