Welcome to our websites!

Allen-Bradley 1336 SP-155977 Control Board Card

Allen-Bradley 1336 SP-155977

1. Overview

Allen-Bradley 1336 SP-155977 belongs to the 1336 FORCE series of AC Drives.

Product Positioning: A high-performance AC motor control system designed for industrial automation environments.

Core Functions: Achieves motor speed control by adjusting power frequency, providing precise torque and speed output.

Application Scope: Mainly used for medium and large motor drives, with a power range covering 0.75 to 485 kilowatts (1 to 650 horsepower).

____________________________________________________________________________________________

2. Specifications

Rated Power: Covers the range of 0.75 kW to 485 kW (1 HP to 650 HP).

Rated Voltage: Typically 460V AC, frequency 50-60Hz.

Power Factor: High power factor design to improve energy efficiency performance.

Protection Level: Offers multiple protection options such as IP00 (Open Type), IP54 (Splash-Proof), and IP65 (Dust and Water-Proof).

Rated Torque: Provides continuous torque control from light load to heavy load; specific values vary by power level.

____________________________________________________________________________________________

3. Product Features

High Bandwidth Control: Adopts advanced IGBT power modules and microprocessor technology, featuring high bandwidth and fast response capabilities to handle special acceleration and deceleration requirements.

Flexible Parameter Setting: The drive’s Parameter Table is easy to program, supporting multiple control modes (such as V/F control, vector control, etc.), facilitating on-site commissioning.

Reliability: Equipped with Non-Volatile RAM (NV-RAM), which can automatically restore parameter settings after power failure to prevent data loss.

Programmable I/O: Supports programmable input/output function blocks, enabling high-precision monitoring and protection of the motor.

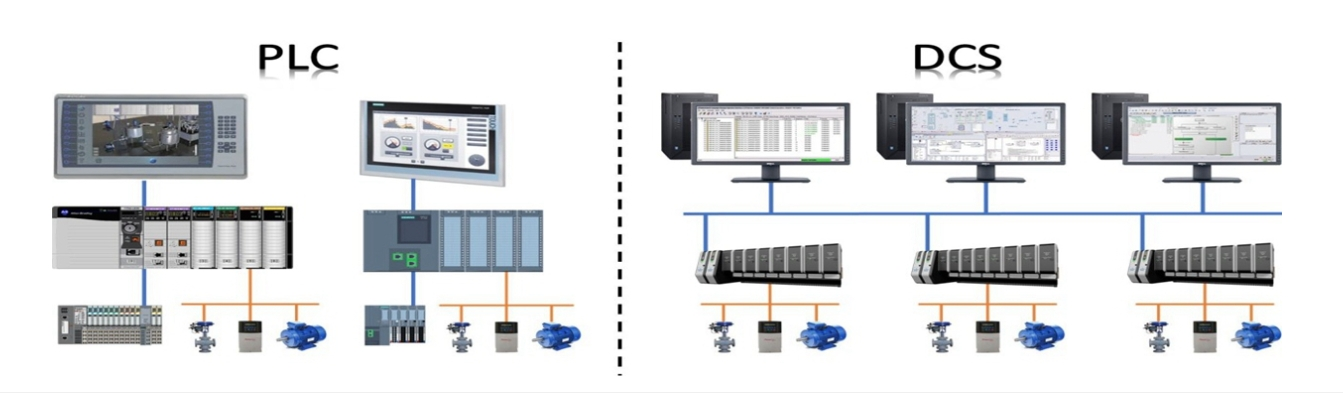

Communication Capability: Usually supports the Ethernet/IP (CIP) protocol, enabling seamless integration with upper computer systems such as PLCs.

____________________________________________________________________________________________

4. Structure and Composition

Main Circuit Board (MCB): Contains power electronic modules (IGBTs), main circuit terminals, and heat dissipation devices, serving as the core component of the drive.

Gate Drive Board (BDB): Responsible for controlling the switching of IGBTs, providing precise PWM signals to ensure the safety and efficiency of the main circuit.

Pre-Charge PCB: Used for pre-charging capacitors to prevent current surges at startup.

Brake Chopper (WB009): Used with the drive to control the connection of the brake resistor, achieving rapid braking of the motor.

Human-Machine Interface Module (HIM): Used for parameter setting and status monitoring; some models are equipped with a display screen.

____________________________________________________________________________________________

5. Application Fields

Material Handling: Equipment requiring precise speed control such as conveyors, hoists, and counters.

Processing and Manufacturing: Including industrial equipment such as extruders and mixers, especially suitable for scenarios requiring high-power motor drives.

Automated Production Lines: Serves as a core frequency conversion control component, cooperating with PLC control systems to achieve industrial automation.

Special Industries: Due to its high-power characteristics, it is also applicable to heavy industry fields such as mining and ports.

____________________________________________________________________________________________

6. Installation and Maintenance

Installation Requirements

Installation Clearance: According to standard installation specifications, a minimum installation clearance of 152.4 millimeters (6 inches) must be reserved at the top, bottom, left, and right sides of the equipment, and the horizontal spacing between two devices is 101.6 millimeters (4 inches) to ensure heat dissipation and maintenance space.

Fixing Method: There are 4 mounting holes at the bottom, which need to be fixed on the cabinet or base with bolts to ensure stability during operation.

Grounding Requirements: Must strictly comply with Electromagnetic Compatibility (EMC) requirements and correctly ground the RFI filter to prevent electromagnetic interference.

Maintenance

Regular Inspection: Regularly check cable connections and terminal tightness to prevent loosening caused by vibration.

Firmware Upgrade: Perform Firmware upgrades as needed to obtain the latest functions and fix known issues.

Fault Diagnosis: The drive is equipped with a self-diagnostic function. When a fault occurs, an error code will be reported on the display screen or through the PLC, facilitating quick troubleshooting.

Environmental Requirements: Ensure the working environment meets the protection level requirements to avoid damage to internal circuits caused by moisture or dust.

————————————————————————————————————-

If you would like to learn more about our products and services, please feel free to contact us at any time!

- Sales Manager : Jinny

- Email : sales5@xrjdcs.com

- Whatsapp/Mobile:+86 15359273791

Global renowned brand cooperation

ABB 丨 GE 丨Allen Bradley 丨 Honeywell 丨 Emerson 丨 Bently Nevada 丨 Westinghouse

Triconex 丨 Foxboro 丨 ICS Triplex 丨 Hima 丨 Schneider 丨 Yokogawa 丨 Woodward

—————————————————————————————

【Reasons to Choose us】

1. Unmatched Quality: Our products are sourced directly from top-tier foreign factories and undergo rigorous testing to ensure exceptional performance.

2. Your Satisfaction Guaranteed: Enjoy peace of mind with our one-year warranty and 15-day return or replacement policy for non-man-made issues.

3. Expert Support: Our 24/7 service hotline provides instant answers to your product questions.

4. Cost-Effective: Direct sourcing from manufacturers means competitive prices and a wide in-stock selection.5. Fast Delivery: Experience quick shipping times thanks to our efficient supply chain.

________________________________________________

________________________________________________

【Delivery Time】

1. Express Shipping (DHL, UPS, FedEx, EMS):3-10 working days is a good rule of thumb. These services prioritize speed and often offer features like next-day or guaranteed delivery by a certain date (for an additional fee).

2. Air Mail (China Post, Hong Kong Post):7-35 working days, depending on the destination country. This is a more budget-friendly option, but it takes longer because it has lower priority for shipment.

【Important Notes】Please follow the product’s instruction manual carefully for installation and debugging to avoid damage to the product.

Write your message here and send it to us