Welcome to our websites!

Allen-Bradley 136-BX040-AN-E frequency converter

Allen-Bradley 136-BX040-AN-E

1. Overview

The Allen‑Bradley 136‑BX040‑AN‑E is a member of the SV+ (Sensorless Vector Plus) series from Rockwell Automation. Designed for medium‑to‑high power industrial applications, this 40 HP (30 kW) drive delivers precise speed and torque control for a wide range of machinery, including machine tools, packaging equipment, textile machines, mining systems, and other automation solutions requiring reliable motion control.

____________________________________________________________________________________________

2. Key Specifications

|

Parameter

|

Specification

|

|---|---|

|

Power Rating

|

40 HP (30 kW)

|

|

Motor Type

|

Three‑phase AC induction motor

|

|

Input Voltage

|

460 V AC

|

|

Output Frequency

|

0 – 400 Hz (other ranges available)

|

|

Control Method

|

Sensorless Vector (SV)

|

|

Efficiency

|

High efficiency, compliant with IEC/EN 61800‑3

|

|

Operating Temperature

|

-20°C to +50°C (depending on mounting)

|

|

Protection Class

|

NEMA 4 or IP20

|

|

Communication

|

EtherNet/IP, DH+ (Profibus/Profinet optional)

|

|

Dimensions

|

7.75 in (196.9 mm) H × 6.75 in (171.5 mm) W × 1 in (25.4 mm) D

|

3. Product Features

- Sensorless Vector Control: Achieves accurate speed and torque regulation without physical feedback devices, reducing system cost and complexity.

- Energy Efficient: Advanced power electronics minimize energy loss and lower operational costs.

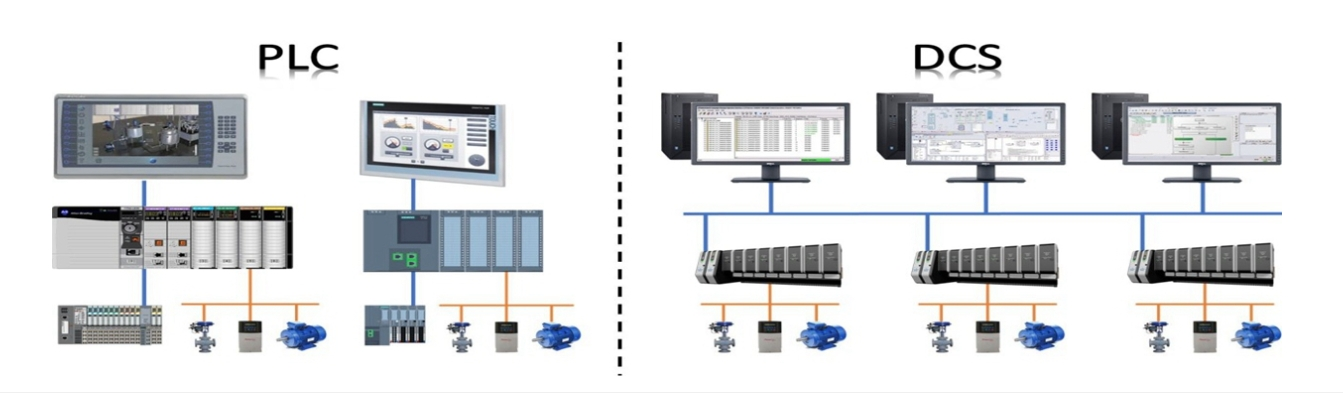

- Flexible Programming: Seamlessly integrates with Allen‑Bradley PLCs via Ladder Logic and EtherNet/IP for easy system configuration.

- Rugged Design: Built to withstand harsh industrial environments with strong resistance to electrical noise and mechanical stress.

____________________________________________________________________________________________

4. Construction and Components

- Power Module: Converts incoming AC power to adjustable voltage and frequency using IGBT or MOSFET technology.

- Control Module: Features a high‑performance microprocessor or DSP to execute vector control algorithms and manage I/O signals.

- Communication Interfaces: Provides EtherNet/IP, DH+, and serial connectivity for remote monitoring and configuration.

- Cooling System: Equipped with fans and heat sinks to ensure stable operation under heavy loads.

____________________________________________________________________________________________

5. Typical Applications

- Machine Tools: Spindle drives for lathes, milling machines, and other equipment requiring precise torque control.

- Packaging Machinery: Synchronized control for winding, conveying, and packaging processes.

- Textile Equipment: High‑efficiency and accurate speed control for textile manufacturing.

- Fans and Pumps: Variable speed operation to match load requirements and reduce energy consumption.

____________________________________________________________________________________________

6. Installation and Maintenance

- Space Requirements: Allow at least 6 inches (152.4 mm) of clearance on all sides for proper ventilation and maintenance.

- Electrical Wiring: Follow local electrical codes (e.g., GB 50303) to ensure secure connections and minimize electrical interference.

- Cooling Maintenance: Regularly clean air inlets and outlets, and check fan operation to maintain optimal heat dissipation.

- Parameter Backup: Before commissioning, back up original parameters via EtherNet/IP to prevent startup issues after adjustments.

____________________________________________________________________________________________

7. Common Issues and Troubleshooting

- Inaccurate rotor position detection: Ensure a stable three‑phase power supply and avoid voltage imbalance or harmonic distortion.

- Frequent overcurrent trips: Check for motor overload, rotor jamming, or excessive mechanical load.

- Communication failures: Verify IP address settings, use shielded Ethernet cables, and confirm correct node configuration in the PLC program.

————————————————————————————————————-

If you would like to learn more about our products and services, please feel free to contact us at any time!

- Sales Manager : Jinny

- Email : sales5@xrjdcs.com

- Whatsapp/Mobile:+86 15359273791

Global renowned brand cooperation

ABB 丨 GE 丨Allen Bradley 丨 Honeywell 丨 Emerson 丨 Bently Nevada 丨 Westinghouse

Triconex 丨 Foxboro 丨 ICS Triplex 丨 Hima 丨 Schneider 丨 Yokogawa 丨 Woodward

—————————————————————————————

Your Trusted Partner for DCS Spare Parts Supply

We are a professional DCS (Distributed Control System) spare parts supplier, dedicated to providing high-quality products and comprehensive services to global customers. With years of industry experience, we have established a solid reputation in the DCS spare parts market, focusing on meeting the diverse needs of customers in industrial automation fields.

1. Strong Professionalism

Focused Field

Long-term focus on DCS spare parts sales, with in-depth understanding and rich experience in products of multiple well-known brands such as ABB, FOXBORO, TOSHIBA, ALSTOM, HITACHI, etc. Our professional team can accurately grasp the characteristics and application scenarios of various brand products, providing targeted solutions for customers.

Technical Support

Provide professional technical support services. Our technical team is composed of experienced engineers who can quickly respond to customer equipment failure problems, provide effective troubleshooting guidance, and help customers improve production efficiency.

2. Rich Product Range

Complete Brand Coverage

Cover multiple internationally renowned brands including ABB, FOXBORO, TOSHIBA, ALSTOM, HITACHI, etc. We have established stable cooperative relations with these brands, ensuring that customers can obtain authentic and high-quality spare parts of their desired brands.

Various Models Available

Provide a full range of DCS spare parts models, covering almost all common and special models in the market. No matter what type of DCS spare parts customers need, we can meet their requirements, avoiding the trouble of customers looking for multiple suppliers.

3. High-Quality Services

Rapid Response

We adhere to the principle of customer first and respond to customer inquiries and needs in a timely manner. Our sales team is on call 24/7 to provide efficient consultation and quotation services, ensuring that customers’ needs are addressed quickly.

Convenient Logistics

Equipped with a complete logistics system, we have established cooperative relations with well-known international logistics companies. We can formulate the most suitable logistics plan according to the customer’s location and urgent needs, ensuring that the goods are delivered to the customer’s hands quickly and safely.

4. Price Advantage

Direct Procurement

Established long-term and stable cooperative relations with original manufacturers, realizing direct procurement of DCS spare parts. By eliminating intermediate links, we can obtain spare parts at preferential prices, laying the foundation for providing customers with cost-effective products.

Cost Control

Implement refined cost control in the whole process of procurement, warehousing, and sales. We strive to reduce unnecessary costs and pass the price advantage directly to customers, helping customers reduce procurement costs.

5. Good Reputation

Years of Experience

With years of experience in DCS spare parts sales, we have served thousands of customers in various industries. Our reliable product quality and thoughtful service have won unanimous praise from customers, accumulating a good market reputation.

Customer-Oriented

Adhere to the customer-centered concept, and provide honest and reliable services for every customer. We take the satisfaction of customers as the goal, and continuously improve the quality of products and services to meet the growing needs of customers.

Why Choose Us?

- Save Time and Effort: One-stop procurement service, integrating various brands and models of DCS spare parts. Customers only need to contact us to complete the procurement of all required spare parts, reducing the time and energy spent on looking for spare parts.

- Quality Assurance: All products are original genuine products, passing strict quality inspection before leaving the factory. We ensure the quality of each spare part, ensuring the stable operation of customers’ equipment.

- Affordable Price: With strong price competitiveness, we provide customers with high-quality products at preferential prices, helping customers reduce production and operation costs and improve market competitiveness.

Write your message here and send it to us