Welcome to our websites!

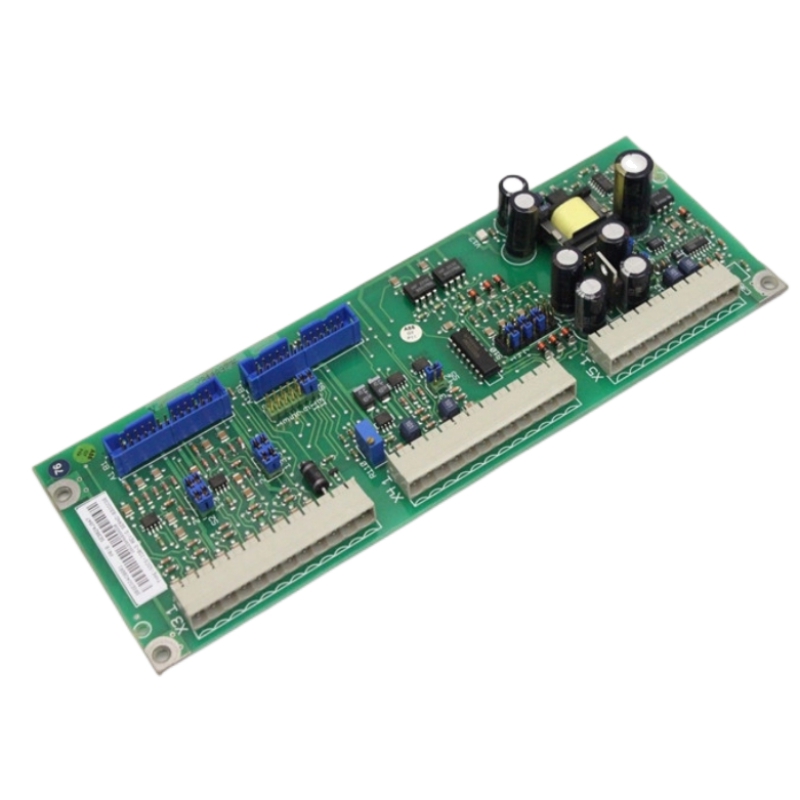

ABB ISO25/3R3 I/O module

ABB ISO25/3R3

1. Overview

ABB ISO25/3R3 is an industrial automation component launched by ABB, primarily used for signal processing and control in industrial automation systems. It belongs to ABB’s I/O module series and is suitable for various industrial environments, such as production line control, machining, logistics control, etc. The device supports multiple communication protocols, such as Modbus, and features high stability and reliability, making it suitable for long-term operation in industrial settings.

2. Parameters

- Input/Output Range: Varies according to specific models, but generally supports digital and analog input/output.

- Power Voltage: Typically 24V DC (direct current).

- Operating Temperature: -20°C to +60°C.

- Protection Level: IP20, suitable for general industrial environments.

- Installation Method: DIN rail installation.

- Communication Interfaces: Supports multiple communication protocols, such as Modbus and EtherNet/IP.

3. Product Features

- Modular Design: Facilitates installation, maintenance, and expansion, suitable for industrial automation systems of different scales.

- High Reliability: Stable and reliable design for long-term operation in industrial environments.

- Flexible Configuration: Can be flexibly configured according to different application requirements.

- Multiple Communication Protocols Support: Compatible with various industrial communication protocols (e.g., Modbus, EtherNet/IP), enabling easy integration with other systems.

4. Structure and Composition

ABB ISO25/3R3 typically consists of the following components:

- Digital Baseplate Units: Such as DSQC1030, used for connecting and managing I/O modules.

- Safety Digital Baseplate Units: Such as DSQC1042, used for safety-related I/O signals.

- Additional Devices: Such as DSQC1031, DSQC1032, DSQC1033, etc., for expanding I/O functions.

- Connectors: Supports multiple interface types (e.g., PE ISO25, PE ISO32) for easy connection to external devices.

5. Application Areas

ABB ISO25/3R3 is widely used in the following fields:

- Production Line Control: Monitors and controls various sensors and actuators on production lines.

- Machining: Applies to automation control of machine tools and processing equipment.

- Logistics Control: Used for automated management of warehousing and logistics systems.

- Industrial Robots: Serves as part of robot control systems for signal processing and control.

6. Installation and Maintenance

- Installation: Commonly uses DIN rail installation for easy setup and maintenance. During installation, pay attention to environmental temperature and humidity to ensure normal operation.

- Maintenance: Regularly inspect the connection and communication status of I/O modules to ensure stable operation. Maintenance includes cleaning, tightening, and replacing damaged components. ABB provides detailed maintenance guidelines, which users can obtain through official documents or by contacting customer support.

———————————————————————————————————————————

If you would like to learn more about our products and services, please feel free to contact us at any time!

- Sales Manager : Jinny

- Email : sales5@xrjdcs.com

- Whatsapp/Mobile:+86 15359273791

Global renowned brand cooperation

ABB 丨 GE 丨Allen Bradley 丨 Honeywell 丨 Emerson 丨 Bently Nevada 丨 Westinghouse

Triconex 丨 Foxboro 丨 ICS Triplex 丨 Hima 丨 Schneider 丨 Yokogawa 丨 Woodward

—————————————————————————————

Advantages

- Large inventory & fast delivery

- Competitive prices & prompt quotation

- Product information and images provided

- Professional services & technical support

- 1-year warranty

- Machine testing before shipment

Payment

T/T (wire transfer)/PayPal/Western Union/MoneyGram

Shipping

Delivery via DHL/FedEx/TNT/UPS/EMS… You can choose your preferred shipping method

▲ With senior PLC programmable (automation system) technical engineers and hydrogen production system design & development engineers

▲ Specialized in R&D, production, sales, and after-sales service of hydrogen production and supply systems, with rich practical experience in design, installation, debugging, operation, and maintenance of hydrogen production and supply projects

▲ Also specialized in automation transformation, maintenance, and overhaul of old unit hydrogen production systems. Accumulated extensive installation, debugging, and operation experience through serving numerous domestic and international manufacturers, providing users with high-quality, timely, and dedicated services in system management, operation, and business aspects

▲ PLC system transformation, PLC control cabinets, Schneider PLC system transformation, Allen Bradley PLC programming, semi-automatic/full-automatic electrical power cabinets, professional program writing to solve your automation control challenges

▲ System engineering: automation system design & development, debugging, low-voltage distribution cabinets, frequency converter control systems, PLC automatic control systems, various energy-saving complete system

Write your message here and send it to us