Welcome to our websites!

ABB PCS6000 PRODUCE FAMLIY medium voltage wind turbine generator

ABB PCS6000 PRODUCE FAMLIY

The medium-voltage full-power converters of the ABB PCS6000 PRODUCT FAMILY are designed specifically for large turbines. Their features include a reduced number of components, high availability, and minimized losses. The higher voltage level of the MV converters results in lower currents in the electrical drive system, while the converters are also easier to integrate into turbines. These converters can be designed for nacelle or tower base installation, and their modular design makes it easy to customize them to meet customer requirements. Additionally, they have the capability of fault-ride-through and compliance with grid regulations.

The ABB PCS6000 is one of the core product lines of ABB medium-voltage frequency converters.

It is designed specifically for industrial applications to achieve precise speed control of AC motors.

Core objectives: Improve energy efficiency, optimize processes, and enhance equipment reliability.

Technical foundation: Based on Modular Multilevel Converter (MMC) technology (for specific voltage levels).

Positioning: A solution with high power density and high reliability.

Parameters

- Voltage levels: 3.3 kV, 4.16 kV, 6.6 kV, 6.9 kV, 10 kV, 11 kV.

- Power range: Typically covers approximately 1 MW to 28 MW and above (depending on voltage and model).

- Output frequency: 0 to 120 Hz (standard), customizable to higher frequencies.

- Efficiency: Usually > 98% (including transformer).

- Input power factor: Close to 1 (no additional power factor compensation device required).

- Overload capacity: Typically 110% continuous operation, 120% for 60 seconds, 150% for 2 seconds.

- Control accuracy: Speed control accuracy is usually better than 0.1% (open-loop), 0.01% (closed-loop).

- Protection class: Cabinets are usually IP21, IP31, IP42 or higher (depending on configuration and application requirements).

Product Features

- Excellent energy efficiency: Four-quadrant operation capability (regenerative energy feedback to the grid) and high system efficiency.

- Perfect grid performance: Extremely low harmonic distortion (THiD < 3-5% @ full load), high input power factor (~1), compliant with strict grid specifications.

- Outstanding motor performance: High-quality sinusoidal output current/voltage, low dv/dt, protection of motor insulation, reduction of bearing current risk, support for standard asynchronous motors and permanent magnet motors.

- High reliability:

- Modular design (redundancy of key components optional).

- Robust power semiconductor design.

- Advanced cooling system (air-cooled or water-cooled).

- Built-in diagnostic and monitoring functions.

- Flexibility and scalability:

- Modular architecture facilitates maintenance and upgrades.

- Multiple cabinet sizes and configurations available.

- Easy integration into automation systems (supporting multiple communication protocols).

- User-friendliness:Low maintenance requirements: Long-life design with predictive maintenance support.

- Graphical control panel/human-machine interface (HMI).

- Intuitive debugging and parameter setting tools.

- Comprehensive diagnostic and event recording functions.

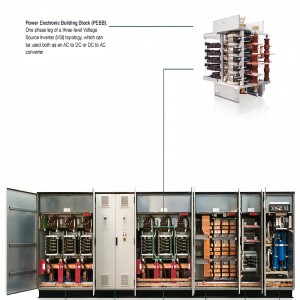

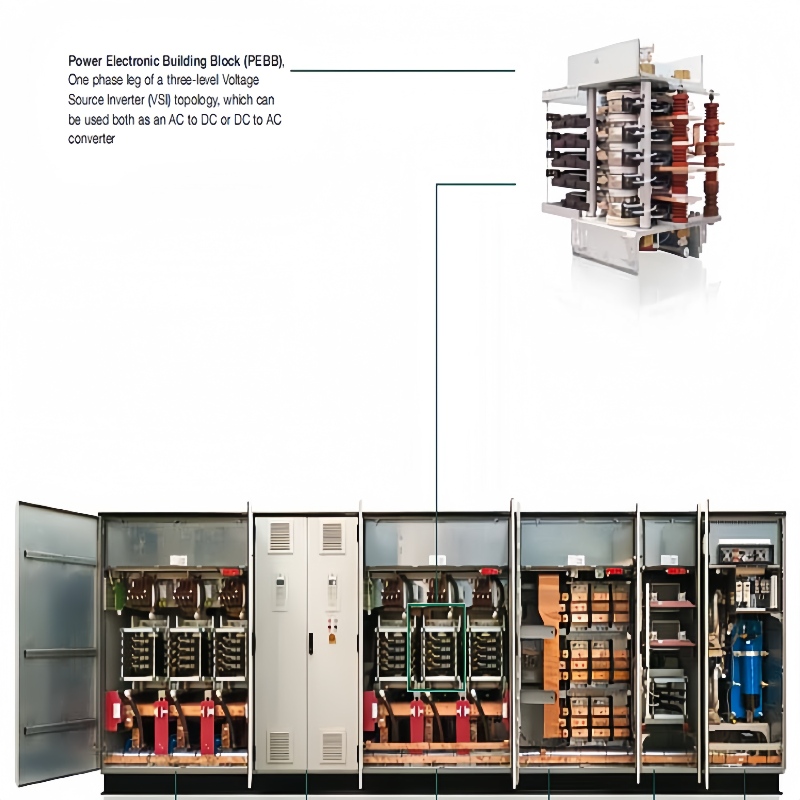

Structure and Composition

- Input transformer (optional but common): Provides electrical isolation, voltage matching, reduces common-mode voltage, and minimizes harmonics.

- Rectifier/input unit:DC bus: Energy storage and transmission link.

- Based on power semiconductors such as IGCT/IGBT.

- Implements grid-side Active Front End (AFE) to ensure four-quadrant operation and low harmonics.

- Inverter/output unit:

- Also based on IGCT/IGBT and other components.

- Converts DC power into three-phase AC power with adjustable frequency and voltage to drive motors.

- Adopts multilevel topologies (such as NPC, CHB, MMC) to obtain high-quality output waveforms.

- Control unit:Cooling system: Forced air cooling (fans) or water cooling system to ensure power devices operate at safe temperatures.

- Core processor (DSP/FPGA).

- Implements motor control algorithms (V/f, vector control, DTC optional).

- Handles communication, I/O, and protection logic.

- Operation monitoring system.

- Switchgear and protection devices: Include input/output circuit breakers, contactors, protection relays, fuses, etc.

- Human-machine interface (HMI): Local operation panel for monitoring, parameter setting, and fault checking.

- Interface and communication: Digital/analog I/O terminals; support for fieldbuses (such as Profibus DP, Modbus TCP, Ethernet/IP, CANopen, etc.).

- Sensor interface: Used to connect motor speed/position feedback (encoder/resolver).

Application Fields

- Mining: Large fans, water pumps, mills, belt conveyors, hoists.

- Metallurgy: Main drives of rolling mills, fans, water pumps, compressors, roller tables.

- Oil and gas: Pipeline compressors, water injection pumps, main fans/compressors on offshore platforms.

- Water and wastewater treatment: Large water intake pumps, water supply pumps, sewage lift pumps, aeration fans.

- Power industry: Boiler feed pumps, induced draft fans, forced draft fans, circulating water pumps, condensate pumps.

- Chemical and petrochemical industry: Large compressors, pumps, mixers, extruders.

- Cement industry: Raw material mills, cement mills, fans, crushers.

- Pulp and paper industry: Pulpers, paper machines, fans, compressors.

- Marine industry: Main propellers, thrusters, large pumps/fans (requiring classification society certification).

- Test benches: High-power motor/engine test platforms.

Installation and Maintenance

Installation

- Environmental requirements: Clean, dry, well-ventilated, free of corrosive gases, ambient temperature/humidity in line with specifications, and sufficient space (operation and maintenance channels).

- Foundation: Solid and level concrete foundation.

- Electrical connections: Strictly follow the drawings for high-voltage input, motor output, auxiliary power, and grounding (extremely important) connections. Professional high-voltage electricians are required for operation.

- Cooling system connections: Ensure unobstructed air ducts or correct water circuit connections (for water-cooled models), with flow/pressure/water quality up to standard.

- Control system integration: Connect I/O signal lines and communication buses.

Commissioning

- Pre-power-on inspection (insulation, wiring, mechanics).

- Auxiliary power-on test.

- Control software parameter configuration (motor data, application macros, protection settings, etc.).

- No-load test (output voltage, waveform, phase sequence).

- No-load test with motor (rotation direction, basic control).

- Load test and optimization (speed loop, current loop tuning).

Maintenance

-

Regular inspection:

- Cleaning: Regularly remove dust inside and outside the cabinet (after power off!), ensure radiators/filters are clean, and fans operate normally (for air-cooled models).

- Electrical connection inspection: Tighten main circuit and control circuit terminals (according to specified torque, usually requiring power outage).

- Cooling system inspection: Fan status (air-cooled), water pump, pipeline, filter, and coolant status (water-cooled).

- Status of key components: Capacitor appearance (no bulging, leakage), resistor status, etc.

-

Preventive maintenance:

- Replace cooling fans according to operating time and environmental conditions.

- Replace coolant and filters in the water cooling system (for water-cooled models).

- Inspect, clean, or replace dust filters.

- Perform functional tests (such as protection function verification).

-

Condition monitoring:

- Use built-in diagnostic tools to monitor operating parameters (temperature, current, voltage, fault records).

- Analyze operating data to predict potential faults.

-

Fault handling:

- Refer to the fault codes and information displayed on the HMI.

- Consult the manual for fault diagnosis and troubleshooting.

- Replace faulty modules (benefiting from modular design).

-

Spare parts management: Reserve key wearing parts and modules.

———————————————————————————————————————————

If you would like to learn more about our products and services, please feel free to contact us at any time!

- Sales Manager : Jinny

- Email : sales5@xrjdcs.com

- Whatsapp/Mobile:+86 15359273791

Global renowned brand cooperation

ABB 丨 GE 丨Allen Bradley 丨 Honeywell 丨 Emerson 丨 Bently Nevada 丨 Westinghouse

Triconex 丨 Foxboro 丨 ICS Triplex 丨 Hima 丨 Schneider 丨 Yokogawa 丨 Woodward

—————————————————————————————

Xiamen Xingruijia Import and Export Co., Ltd.

Since its establishment, Xiamen Xingruijia Import and Export Co., Ltd. has maintained a steady development momentum. We continuously expand our product range, increase market share, and enhance brand influence. In the future, we will continue to adhere to the business philosophy of “customer first, integrity-based” to create greater value for customers.

About Logistics

- Geographical Advantages: Located in Xiamen, an important port city, we rely on convenient maritime, air, and land transportation networks to quickly realize domestic and international transportation and shorten delivery time.

- International Logistics Network: Cooperating with global logistics companies, we provide a variety of transportation options, including sea freight and air freight, to ensure that goods are delivered to all parts of the world safely and efficiently.

- Flexible Transportation Methods: According to customer needs, we offer various solutions such as door-to-door service, LCL (Less than Container Load), and FCL (Full Container Load) to help customers reduce costs and improve efficiency.

- Real-time Logistics Tracking: We support real-time tracking of goods, allowing customers to keep abreast of the transportation status at any time to ensure on-time delivery.

- Professional Customs Declaration Services: We provide fast customs declaration and tariff consultation services to ensure smooth customs clearance of international goods and reduce delays.

- High-standard Packaging: We adopt international standard packaging to ensure that goods are safe and undamaged during transportation, and also support customized packaging solutions.

Write your message here and send it to us