ABB TU836V1 module termination unit

ABB TU836V1

1. Overview

The ABB TU836V1 is an extended Module Termination Unit (MTU) in the ABB S800 I/O system, primarily used to connect signal lines between I/O modules and field devices. By providing multiple I/O channels, it enables control and monitoring of industrial automation systems. This module is typically deployed in high-reliability and safety-critical industrial environments, such as process control, machine automation, and factory automation.

2. Specifications

- Voltage: 250 V

- Current: 3 A per channel

- Number of Channels: 8 I/O channels

- Fuses: 2 fuses per channel

- Dimensions: Depth 64 mm, Height 110 mm, Weight 0.26 kg

- Operating Temperature: -25°C to 55°C

- Communication Protocols: Supports multiple protocols, including Ethernet, Profibus, and Modbus.

3. Key Features

- High Reliability: Designed to meet industrial standards, ensuring long-term operation in harsh environments.

- Flexible I/O Channels: 8 configurable I/O channels, supporting various types such as digital input/output (DI/DO) and analog input/output (AI/AO).

- Safety Design: Each channel is equipped with fuses to protect circuits from damage in case of faults.

- Compatibility: Fully compatible with the ABB S800 I/O system and other ABB devices, facilitating easy integration and expansion.

- Easy Installation: Features terminal block connections for simple setup and maintenance.

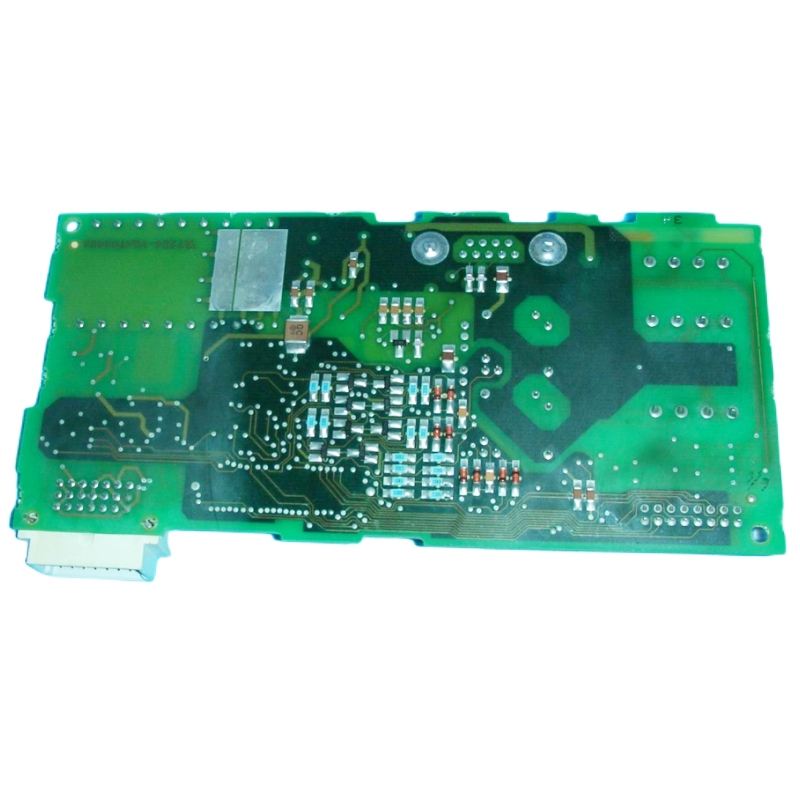

4. Structure and Components

The ABB TU836V1 consists of the following key components:

- Module Body: Houses I/O channels and connectors for linking I/O modules and field devices.

- Fuses: 2 fuses per channel for circuit protection.

- Connectors: Multiple interfaces for connecting I/O modules and signal lines.

- ModuleBus: Includes a ModuleBus section for inter-module communication.

5. Applications

The ABB TU836V1 is widely used in the following industrial sectors:

- Process Control: Monitors and regulates parameters like temperature, pressure, and flow.

- Machine Automation: Controls robotic movements, equipment start/stop, and more.

- Factory Automation: Enables automated control of entire production facilities.

- Power Systems: Used for monitoring and managing electrical grids.

- Transportation Systems: Supports automation in traffic and transport infrastructure.

6. Installation & Maintenance

Installation:

- Ensure all tools and materials are prepared before installation.

- Mount the module in the designated I/O module slot.

- Securely connect I/O modules and signal lines using terminal blocks.

- Configure communication parameters for compatibility with other devices.

Maintenance:

- Regularly inspect connections to ensure no loose or damaged wiring.

- Check fuses and replace them if faulty.

- Use ABB-approved maintenance tools for diagnostics and servicing.

- Keep detailed maintenance logs for future reference and troubleshooting.

———————————————————————————————————————————

If you would like to learn more about our products and services, please feel free to contact us at any time!

Sales Manager : Jinny

Email : sales5@xrjdcs.com

Whatsapp/Mobile:+86 15359273791

Global renowned brand cooperation

ABB 丨 GE 丨Allen Bradley 丨 Honeywell 丨 Emerson 丨 Bently Nevada 丨 Westinghouse

Triconex 丨 Foxboro 丨 ICS Triplex 丨 Hima 丨 Schneider 丨 Yokogawa 丨 Woodward