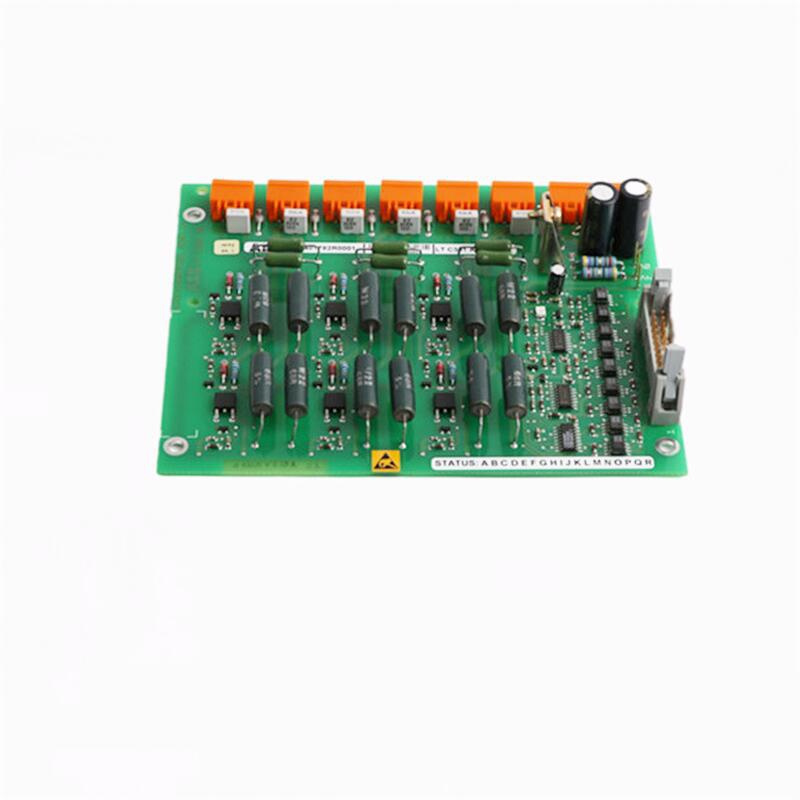

ATLAS PF300-G-HW Communication Interface Module

ATLAS PF300-G-HW

Product Overview

Core Parameters & Technical Specifications

|

Parameters

|

Description

|

|---|---|

|

Communication Interface

|

DeviceNet, Ethernet, RS232, Digital I/O

|

|

Compatible Tools

|

Tensor ST, ES, ETX and other electric tools

|

|

Control Mode

|

Torque Control, Angle Control, Multi-stage/Composite Control

|

|

Process Functions

|

Supports slip/omission/under-torque detection and automatic re-tightening

|

|

Program Capacity

|

Supports storage and switching of hundreds of tightening programs

|

|

Installation Method

|

Standard industrial rail mounting or control cabinet embedded mounting

|

_______________________________________________________________________________________________________

Product Features

- High-Precision Control: Configurable via ToolsTalk PF software, enabling high-precision torque and angle control to ensure assembly accuracy.

- Powerful Communication Capability: Built-in DeviceNet interface, supporting seamless integration with PLC and MES systems to realize data traceability and process management.

- Multi-Function Integration: Supports slip, omission and under-torque detection as well as automatic re-tightening, effectively guaranteeing assembly quality.

- Flexible Installation: Compatible with standard industrial rail mounting, easy to integrate into existing production lines.

_______________________________________________________________________________________________________

Structure & Composition

- Control Host: The core control unit, including CPU and display screen, responsible for overall operation control.

- Communication Module: Responsible for the communication of protocols such as DeviceNet, ensuring stable data transmission.

- Power Module: Provides AC 100–240V power input to supply power for the entire controller.

- Tool Interface: The interface for connecting tensioning tools (such as Tensor series), enabling signal transmission between the controller and tools.

_______________________________________________________________________________________________________

Application Fields

- Automotive Manufacturing: Tightening of key bolts for engines, gearboxes, chassis and body structural parts.

- New Energy Vehicles & Battery Manufacturing: High-precision assembly tasks such as power battery modules, electric drive systems and electronic control boxes.

- Construction Machinery & Rail Transit: High-torque fastening of structural part connections, braking systems and suspension components.

- Industrial Automation: Cooperating with robot assembly to realize automatic linkage and improve production efficiency.

_______________________________________________________________________________________________________

Installation & Maintenance

Installation

Maintenance

————————————————————————————————————-

If you would like to learn more about our products and services, please feel free to contact us at any time!

- Sales Manager : Jinny

- Email : sales5@xrjdcs.com

- Whatsapp/Mobile:+86 15359273791

Global renowned brand cooperation

ABB 丨 GE 丨Allen Bradley 丨 Honeywell 丨 Emerson 丨 Bently Nevada 丨 Westinghouse

Triconex 丨 Foxboro 丨 ICS Triplex 丨 Hima 丨 Schneider 丨 Yokogawa 丨 Woodward

—————————————————————————————

Our advantage

* Foreign direct procurement, genuine products, price concessions, after-sales warranty, complete models, superior inventory.

* All spare parts are guaranteed for 1 year and certified by professional testing.

* If you need to order more than 1 product, please contact us and we can offer you a discount.

* We only use SF Express to deliver spare parts.

* If you find other suppliers offering the same product at a lower price, we are also willing to offer you further discounts based on their prices. If you have any further questions, please feel free to contact us.

* If you have any spare parts, spare parts needs, please tell us, we can provide you with further help, we look forward to your inquiry.

* Credibility, trust and conviction.

* Same product, the difference lies in price and service.

* Your choice is our driving force.