ATLAS PF3007-C-DN-HW Industrial Automation Module

ATLAS PF3007-C-DN-HW

1. Core Overview

- Full Name: PF3007-C-DN-HW Nutrunner Controller

- Product Positioning: An intelligent tightening controller for the medium power segment, part of the Power Focus 3000 series.

-

Model Interpretation:

Core Functions: It is mainly responsible for driving electric nutrunners, executing precise torque and angle control commands, and conducting data interaction with upper computers (such as PLC, MES).

- PF3007: Indicates the medium power segment (3000 series).

- C: Represents the standard control version (Control).

- DN: Supports DeviceNet communication protocol.

- HW: Hardware version.

___________________________________________________________________________________________________________________________

2. Key Technical Parameters

|

Parameters

|

Specifications/Description

|

|---|---|

|

Power Input

|

AC 100–240V (Global Universal)

|

|

Communication Protocol

|

DeviceNet (Main), some models support Ethernet, RS232/RS485

|

|

Control Functions

|

1. Torque Control: Precise torque output2. Angle Control: Rotation angle control3. Multi-stage Control: Execute different torque/angle in stages

|

|

Safety Detection

|

Thread Slip Detection, Under-torque Detection, Missing Tightening Detection

|

|

Automatic Re-tightening

|

Supports automatic detection and compensation of torque deviation to ensure assembly quality

|

|

Storage Capacity

|

Can store hundreds of different tightening programs (the specific number varies slightly by firmware version)

|

3. Product Features & Advantages

- High Intelligence: Equipped with rich safety detection functions, it can automatically identify assembly errors and take remedies, reducing manual intervention.

- Flexible Communication: Supports DeviceNet protocol, easy to integrate into industrial field bus systems, realizing seamless connection with PLC or robot controllers.

- Reliable Precision: Designed specifically for high-torque segments, it can meet the tightening requirements of key components such as automotive engines and chassis.

- Industrial-grade Design: Suitable for harsh production environments, with high anti-interference ability and stability.

___________________________________________________________________________________________________________________________

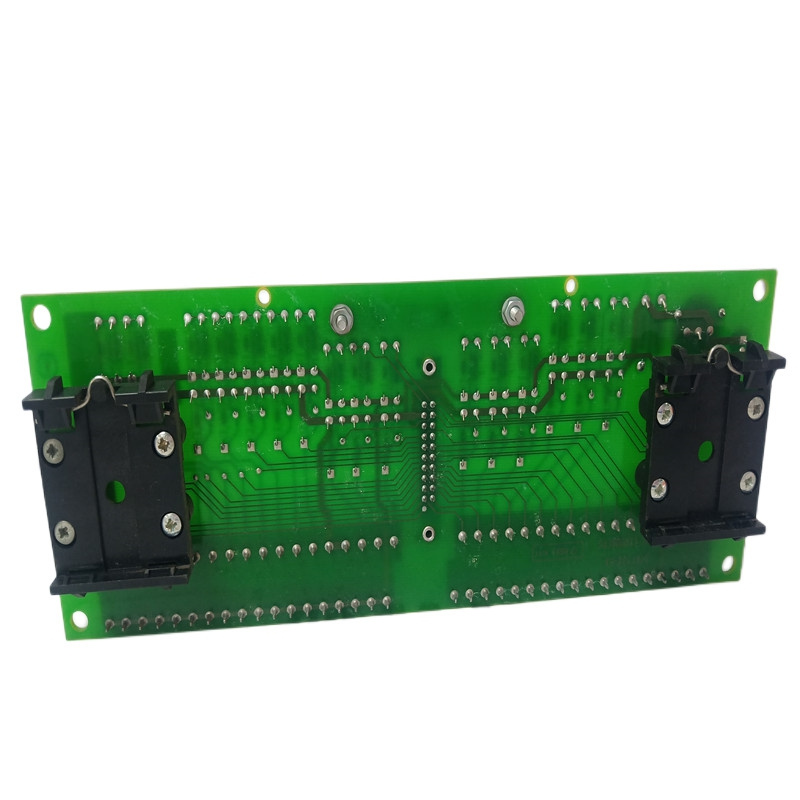

4. Structure & Composition

- Control Mainboard: Includes core processor, I/O interface and communication interface.

- Power Drive Module: Responsible for converting power signals into drive current required by electric nutrunners.

- Display/Operation Panel (Optional): Used for on-site parameter setting and fault indication.

- Mounting Bracket: Used for fixing on guide rails or in control cabinets.

___________________________________________________________________________________________________________________________

5. Main Application Fields

- Automotive Manufacturing: Engine assembly, chassis welding, key bolt tightening of body structural parts.

- Construction Machinery: Connection and maintenance of large structural parts.

- Rail Transit: Car body assembly and fixing of key components.

- Aerospace: High-precision assembly (specific model applicability needs to be confirmed according to configuration).

- Heavy Equipment Manufacturing: Scenarios requiring high-torque tightening such as ships and wind power equipment.

___________________________________________________________________________________________________________________________

6. Installation & Maintenance Recommendations

- Installation Method: This controller is usually fixed using standard industrial guide rails (such as DIN rails) or can be embedded in control cabinets. Please ensure that the wiring with the electric nutrunner complies with the original factory standards (usually 8433 series junction boxes).

- Wiring Inspection: During installation, special attention should be paid to the connection of power wiring and DeviceNet communication lines to ensure no reverse connection or looseness.

- Software Debugging: After connecting to the upper computer, parameter setting should be performed through the debugging software provided by the original factory (such as Power Focus Configuration Tool).

- Regular Maintenance: It is recommended to regularly check the cooling fan and interface of the controller, clean dust, and ensure that the communication lines are free of interference.

————————————————————————————————————-

If you would like to learn more about our products and services, please feel free to contact us at any time!

- Sales Manager : Jinny

- Email : sales5@xrjdcs.com

- Whatsapp/Mobile:+86 15359273791

Global renowned brand cooperation

ABB 丨 GE 丨Allen Bradley 丨 Honeywell 丨 Emerson 丨 Bently Nevada 丨 Westinghouse

Triconex 丨 Foxboro 丨 ICS Triplex 丨 Hima 丨 Schneider 丨 Yokogawa 丨 Woodward

—————————————————————————————

Our Advantages & Service – Product Details

Our Core Advantages

We Focus on Hard-to-Find Spare Parts

- Uncommon spare parts

- Rare spare parts

- Discontinued spare parts

Why Our Products Have More Price Advantages?

- Source purchasing: We purchase directly from the original factory, eliminating price differences caused by intermediate links and reducing your procurement costs.

- Stable channels: We have long-term and stable cooperative relationships with many well-known manufacturers, ensuring sufficient supply and more reliable product sources.

Delivery Time

- In-stock products: After signing the contract and completing the payment, we will arrange delivery immediately.

- Custom-ordered products: Delivery will be arranged in accordance with the quoted delivery time.