ATLAS PF3107-C-DN-HW Control System Module

ATLAS PF3107-C-DN-HW

1. Overview

2. Specifications

- Compatible Tools: Atlas Copco Tensor 3 to Tensor 7 electric torque tools.

- Output Power: Approximately 300 Watts.

- Input Voltage: 90–120V / 180–240V AC, 50/60Hz.

- Control Functions: Supports torque, angle, angle-torque, and speed control modes.

_______________________________________________________________________________________________________

3. Product Features

- High Integration: Integrates a driver, power supply, and communication module into one unit, simplifying system integration.

- Multi-Axis Control: Supports a dual-axis (2C) control version, suitable for complex assembly tasks.

- Flexible Communication: Supports DeviceNet (DN) bus communication, facilitating integration with upper-level systems such as PLCs.

_______________________________________________________________________________________________________

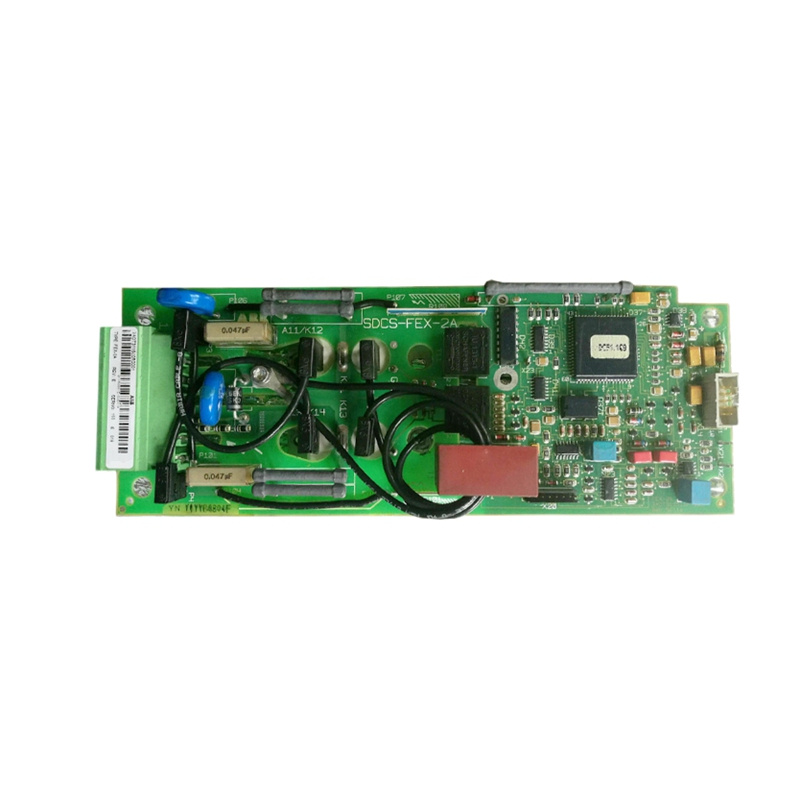

4. Structure and Composition

- Control Unit: Includes a microprocessor and control algorithms.

- Drive Module: Directly drives electric tools.

- Power Supply Module: Responsible for power conversion.

- Communication Interface: Such as the DeviceNet interface.

_______________________________________________________________________________________________________

5. Application Fields

- Aerospace: High-precision assembly of engine components.

- Automotive Manufacturing: Key processes such as body welding and engine assembly.

- Electronic Products: Assembly of precision instruments.

- General Industrial Assembly: Various mechanical assemblies requiring strict torque control.

_______________________________________________________________________________________________________

6. Installation and Maintenance

Installation

Maintenance

7. Frequently Asked Questions (FAQ)

Q1: What is the difference between PF3107-C-DN-HW and PF3007-C-DN-HW?

Q2: Which communication protocols does this controller support?

Q3: Does it support multi-axis control?

Q4: What voltage ranges are required?

Q5: How to upgrade the controller’s software?

————————————————————————————————————-

If you would like to learn more about our products and services, please feel free to contact us at any time!

- Sales Manager : Jinny

- Email : sales5@xrjdcs.com

- Whatsapp/Mobile:+86 15359273791

Global renowned brand cooperation

ABB 丨 GE 丨Allen Bradley 丨 Honeywell 丨 Emerson 丨 Bently Nevada 丨 Westinghouse

Triconex 丨 Foxboro 丨 ICS Triplex 丨 Hima 丨 Schneider 丨 Yokogawa 丨 Woodward

—————————————————————————————

Industrial Control Products & Services – Official Details

Shipping & Related Notes

- We always provide combined shipping discounts for multiple items. The final combined shipping rate will depend on the weight and size of the items.

- We will ship the goods within 1-3 working days after receiving the settlement payment.

- The daily cutoff time for express delivery shipment is 6:00 PM.

- We offer receiving services via TNT, DHL, UPS and FedEx.

- For international buyers: Import duties, taxes and charges are not included in the item price or shipping costs. These charges are the buyer’s responsibility. Please check with your country’s customs office to determine the amount of these additional charges before bidding or purchasing.