ATLAS PF4002-G-HW System Module

ATLAS PF4002-G-HW

1. Overview

2. Technical Parameters

|

Parameter

|

Description

|

|---|---|

|

Model Meaning

|

PF4002: Power Focus 4000 series, 2-level power control range (compatible with small and medium torque tools); G: Advanced version (graphical control); PB/HW: Hardware standard version (integrated PROFIBUS interface)

|

|

Power Supply Specification

|

90-120V / 180-240V AC, 320W, 50-60Hz

|

|

Operating Temperature

|

Maximum ambient temperature: 40°C

|

|

Control Mode

|

Supports multiple tightening logics including torque control, angle control, and combined control

|

|

Language Support

|

Multi-language support, including Chinese and English

|

|

Communication Interface

|

Multiple industrial communication protocols (e.g., Ethernet/IP, PROFIBUS, CANopen)

|

_______________________________________________________________________________________________________

3. Key Features

- Graphical Control (G Version): Equipped with a graphical HMI (Human-Machine Interface), ensuring intuitive and user-friendly operation.

- Industrial-Grade Communication: Built-in PROFIBUS interface (PB version) and supports multiple fieldbuses, facilitating integration into factory automation systems.

- Intelligent Monitoring: Features powerful data recording and traceability functions, suitable for high-precision assembly lines.

- Modular Design: Supports single/multi-channel configuration to meet different production requirements.

_______________________________________________________________________________________________________

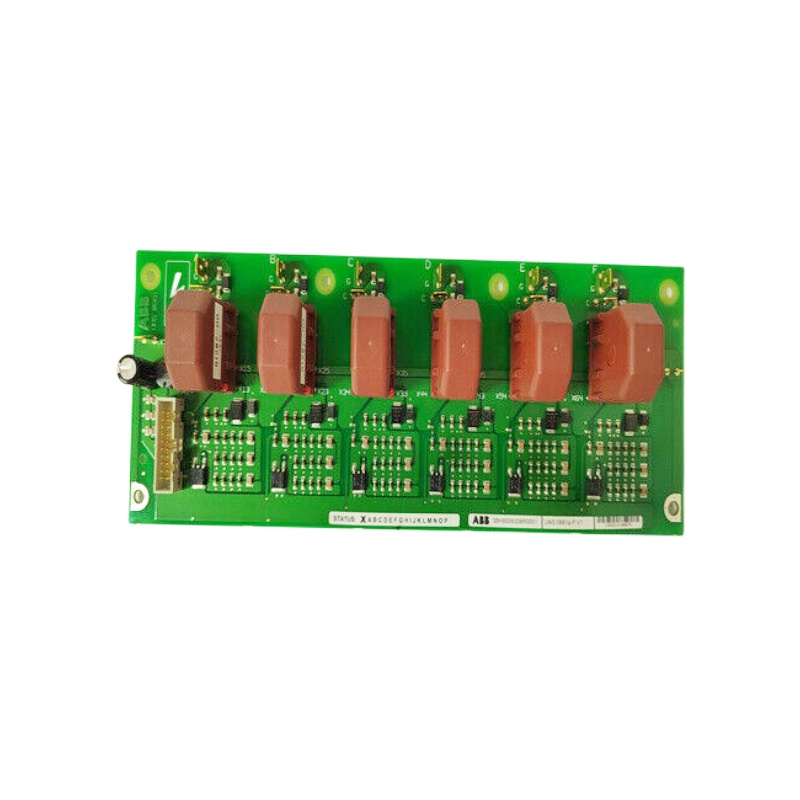

4. Structure & Components

- Controller Unit: Core processor and HMI display, responsible for logical operations and human-machine interaction.

- Power Supply Module: Provides stable power supply with a wide voltage range support.

- Communication Module: Integrates PROFIBUS or other industrial protocol interfaces.

- I/O Interface: Used for connecting electric tools (such as electric torque wrenches) and external sensors.

_______________________________________________________________________________________________________

5. Application Areas

- Automotive Manufacturing: Body, chassis, and engine assembly lines.

- Aerospace: Precision structure assembly.

- High-End Manufacturing: Industrial robot integrated assembly lines.

- Others: High-torque assembly in railway, construction machinery and other fields.

_______________________________________________________________________________________________________

6. Installation & Maintenance

Installation Notes

- Power Connection: Confirm that the voltage specification (90-120V/180-240V) matches the on-site power supply to avoid overvoltage or undervoltage operation.

- Communication Configuration: According to the fieldbus type (e.g., PROFIBUS), correctly connect the communication cable and configure the corresponding communication parameters.

Maintenance Recommendations

- Regular Inspection: Periodically check the power wiring and communication interfaces to prevent communication errors caused by looseness.

- Software Update: Pay attention to firmware updates on the official Atlas Copco website or ServAid platform to obtain the latest function optimizations and security patches.

- Anti-Static Protection: Pay attention to anti-static measures during operation and maintenance to avoid damage to electronic components.

————————————————————————————————————-

If you would like to learn more about our products and services, please feel free to contact us at any time!

- Sales Manager : Jinny

- Email : sales5@xrjdcs.com

- Whatsapp/Mobile:+86 15359273791

Global renowned brand cooperation

ABB 丨 GE 丨Allen Bradley 丨 Honeywell 丨 Emerson 丨 Bently Nevada 丨 Westinghouse

Triconex 丨 Foxboro 丨 ICS Triplex 丨 Hima 丨 Schneider 丨 Yokogawa 丨 Woodward

—————————————————————————————

Industrial Control Products & Services – Official Details

Shipping & Related Notes

- We always provide combined shipping discounts for multiple items. The final combined shipping rate will depend on the weight and size of the items.

- We will ship the goods within 1-3 working days after receiving the settlement payment.

- The daily cutoff time for express delivery shipment is 6:00 PM.

- We offer receiving services via TNT, DHL, UPS and FedEx.

- For international buyers: Import duties, taxes and charges are not included in the item price or shipping costs. These charges are the buyer’s responsibility. Please check with your country’s customs office to determine the amount of these additional charges before bidding or purchasing.