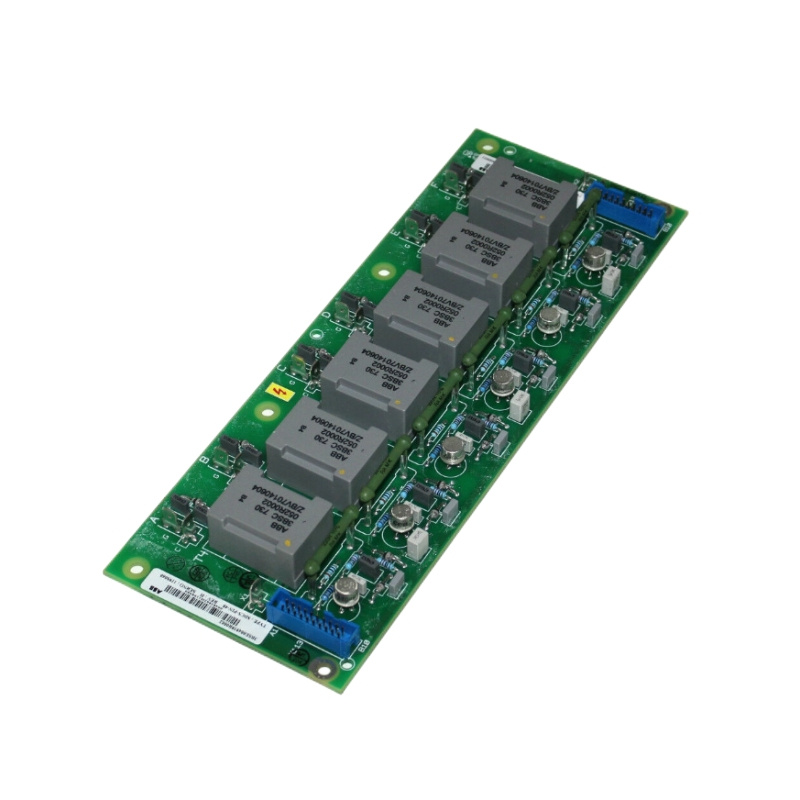

ATLAS PF3107-G-IB-HW System Module

ATLAS PF3107-G-IB-HW

Key Specifications

|

Parameter Category

|

Detailed Specifications

|

|---|---|

|

Drive Type

|

Pneumatic (Air)

|

|

Lubrication Method

|

Oil Lubrication (Oil)

|

|

Maximum Torque

|

6000 – 10000 Nm

|

|

Power Requirement

|

24V DC (for solenoid valve and control system)

|

|

Interface

|

1/2″ (13mm) Pneumatic Interface

|

|

Control System

|

Integrated microprocessor control, supporting industrial communication such as PROFIBUS DP

|

|

Size

|

Large volume, sufficient installation space required

|

|

Weight

|

Heavy (approximately 30-50kg), fixed installation recommended

|

___________________________________________________________________________________________________________________________

Product Features

- High Torque Output: Suitable for high-intensity assembly tasks, such as the tightening of key components like engine bases and drive shafts.

- Oil Lubrication System: Compared with dry-type tightening machines, the oil lubrication system can better reduce internal friction and temperature, extending the service life of the equipment.

- Intelligent Control: Supports torque control, angle control, and adaptive control, capable of real-time monitoring of abnormalities during the tightening process (such as thread slipping, insufficient torque).

- Data Recording and Communication: Integrated PROFIBUS DP interface, which can be connected to the MES system to upload tightening data in real time, meeting the needs of modern intelligent manufacturing.

___________________________________________________________________________________________________________________________

Structure and Composition

- Machine Body: Made of high-strength cast iron or aluminum alloy to ensure rigidity and durability.

- Pneumatic System: Including core components such as pneumatic motor and air valve.

- Oil Lubrication System: Internally integrated with lubricating pump and oil tank.

- Control Unit: Located inside or on the side of the machine body, responsible for processing torque commands and controlling air valve actions.

- Connector: Usually 1/2″ (13mm) connector, used to connect tightening tools.

___________________________________________________________________________________________________________________________

Typical Application Fields

- Automotive Manufacturing: Precision assembly of engines, gearboxes, and chassis components.

- Aerospace: High-torque tightening of large structural parts.

- Heavy Machinery: Assembly of key components such as large gearboxes and compressors.

- Energy Equipment: Tightening of wind turbine towers and generator sets.

___________________________________________________________________________________________________________________________

Installation and Maintenance

Installation Requirements

Maintenance

Safety Tips

————————————————————————————————————-

If you would like to learn more about our products and services, please feel free to contact us at any time!

- Sales Manager : Jinny

- Email : sales5@xrjdcs.com

- Whatsapp/Mobile:+86 15359273791

Global renowned brand cooperation

ABB 丨 GE 丨Allen Bradley 丨 Honeywell 丨 Emerson 丨 Bently Nevada 丨 Westinghouse

Triconex 丨 Foxboro 丨 ICS Triplex 丨 Hima 丨 Schneider 丨 Yokogawa 丨 Woodward

—————————————————————————————

Company philosophy: The company always adheres to the business philosophy of “integrity, efficiency, and win-win”, and serves every new and old customer with the attitude of “integrity service, customer first”. With strong competitive products, large inventory, excellent quality, fast delivery time, and pre-sales consultation and service, we continue to provide products for our customers.

Professional operation of major automation modules, cards CPU、PLC、DCS, The distributed products are widely used in CNC mechanical metallurgy, petrochemicals, chemical engineering, paper printing, textile printing and dyeing, machinery, electronic manufacturing, automobile manufacturing, plastic machinery, electricity, water conservancy, water treatment/environmental protection, municipal engineering, boiler heating, energy, power transmission and distribution, etc.

★ ABB (AC800M/AC800F/AC800PEC/AC900F/excitation control)

★ GE VMIVME/VMIC series CPU motherboard

Relay protection device SR469/SR369/SR489/SR750

IS200/IS215/IS220/ IS420/ DS200/DS215

/IC693/IC694/IC695/IC697/IC698

★ Envision (3008, 3625, 3508E. 3721, 3700A 4351B security system module)

★ Bentley (3500/42M, 3500/22M, 3500/95.3500/05)

Woodward 9907 series 505 speed regulator, 8840 series controller, module

★ Foxboro (FBM230, FBM232, FCP270, H90/H92)

★ Emerson Westinghouse module 1C311/1C312, DELTAV module EPRO sensor

★ Black Horse (F3330, F3236, F6217, F7126, F8621A)

★ Schneider Modicon 140 series CPU, communication module ELAU servo

★ AB: (PLC 1756CPU2094 controller 2711 series touch screen)

★ PROSOFT MVI46/56/69, AB’s communication module