Schneider AEG AS-9584-000 Induction Motor

Schneider AEG AS-9584-000

1. Overview

2. Key Specifications

| Parameter | Value | Description |

|---|---|---|

| Rated Power | 7.5 kW (10 HP) | Common power rating for industrial applications |

| Rated Voltage | 380 V / 400 V / 415 V (3-Phase) | Compatible with mainstream power grids in Europe and Asia |

| Rated Frequency | 50 Hz / 60 Hz | Dual-frequency optional for global use |

| Rated Speed | 1450 r/min (50 Hz) / 1800 r/min (60 Hz) | Standard synchronous speed |

| Rated Current | 13.5 A (380 V) | Reference value under rated voltage |

| Power Factor | 0.85 (Full Load) | Meets IE2 efficiency grade requirements |

| Efficiency | 86 % (IE2) | Compliant with international energy efficiency directives |

| Insulation Class | Class F (155 °C) | Ensures long-term stable operation |

| Protection Class | IP55 | Dust and water protection |

| Mounting Method | Flange Mount (B3) / Threaded Mount (C1) | Customizable for on-site requirements |

| Weight | Approx. 55 kg | Weight of cast iron housing |

3. Structure & Components

- Stator: Laminated with high-permeability silicon steel sheets and equipped with three-phase copper windings to provide a stable magnetic field.

- Rotor: Squirrel-cage aluminum conductor (standard) or copper conductor (optional), with rotor core made of high-strength cast iron.

- Bearings: Double-row deep groove ball bearings with dust covers, supporting both axial and radial loads.

- End Covers: Cast iron end covers with built-in cooling fins to enhance heat dissipation efficiency.

- Terminal Box: Compliant with IEC 60204‑1 standard, fitted with a protective cover for safe wiring.

- Cooling System: Natural air cooling via housing cooling fins; forced air cooling fan can be added if required.

4. Typical Application Fields

- Pumping Stations: Drive for self-priming pumps, centrifugal pumps and screw pumps.

- Fans & Blowers: Main drive for industrial ventilation and air conditioning systems.

- Compressors: Direct drive for screw compressors and piston compressors.

- Conveying Systems: Power source for belt conveyors and screw conveyors.

- Processing Machinery: Equipment requiring constant speed, such as punching machines, sawing machines and packaging machinery.

5. Installation & Maintenance Guidelines

- On-site Inspection: Confirm the foundation platform is level, and the fixing bolt holes match the motor flange dimensions.

- Axis Alignment: Use a laser level or micrometer to ensure coaxiality between motor shaft and drive shaft before installation, with alignment error ≤ 0.1 mm.

- Electrical Wiring: Follow IEC 60204‑1 standards; use copper bars or terminals matching the rated current in the terminal box, with grounding resistance ≤ 0.5 Ω.

- Lubrication Maintenance: Check bearing grease every 2000 operating hours (or 12 months) and replace if necessary.

- Temperature Monitoring: Monitor stator temperature during operation; temperature rise should not exceed 55 °C. If exceeded, check ventilation or install forced air cooling.

- Vibration Detection: Conduct full-frequency vibration testing with a handheld vibrometer every 6 months. Shut down immediately for inspection if abnormal vibration ≥ 4.5 mm/s (check rotor balance or bearing wear).

- Regular Cleaning: Keep the housing surface clean to avoid dust blocking cooling fins; clean with a soft brush or low-pressure air when needed.

If you would like to learn more about our products and services, please feel free to contact us at any time!

- Sales Manager : Jinny

- Email : sales5@xrjdcs.com

- Whatsapp/Mobile:+86 15359273791

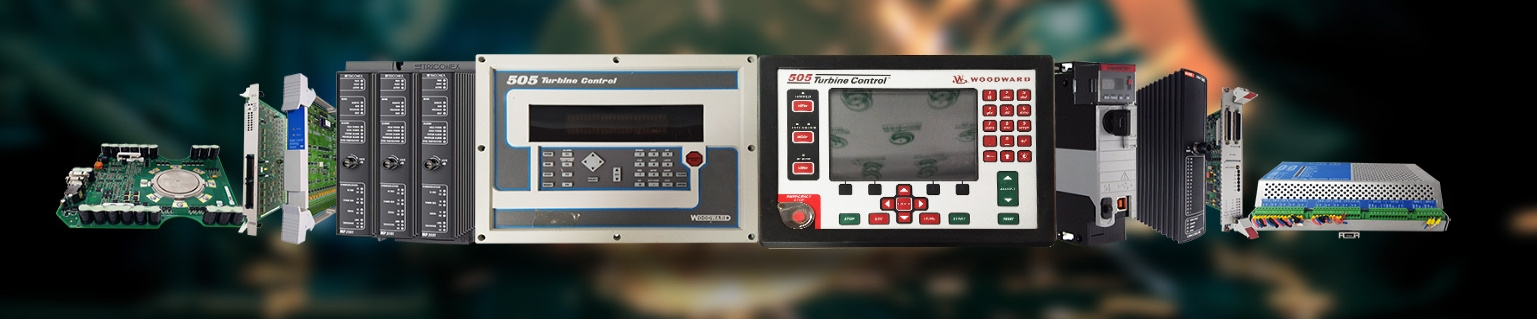

Global renowned brand cooperation

ABB 丨 GE 丨Allen Bradley 丨 Honeywell 丨 Emerson 丨 Bently Nevada 丨 Westinghouse

Triconex 丨 Foxboro 丨 ICS Triplex 丨 Hima 丨 Schneider 丨 Yokogawa 丨 Woodward

—————————————————————————————

1.Reduce Maintenance Costs: We help you cut down equipment maintenance expenses by providing high-quality spare parts and professional services.

2.Minimize Downtime: Fast spare parts supply reduces equipment downtime and boosts overall production efficiency.

3.Extend Equipment Lifespan: Using genuine or compatible premium spare parts effectively prolongs your equipment’s service life.

4.One-Stop Global Supply of PLC Spare Parts: Whatever brand or model of PLC spare parts you need, we deliver fast and accurate solutions.

5.Professional Team & Technical Support: Our team of experienced engineers provides you with professional technical support and reliable repair services.

6.Genuine-Quality Products at Competitive Prices: All our PLC spare parts are genuine or compatible alternatives, ensuring top-tier quality while offering more favorable pricing.

7.Fast Response & Global Shipping: With a sound logistics system, we respond to your needs quickly and deliver spare parts to you in a timely manner.

Our Advantageous Services