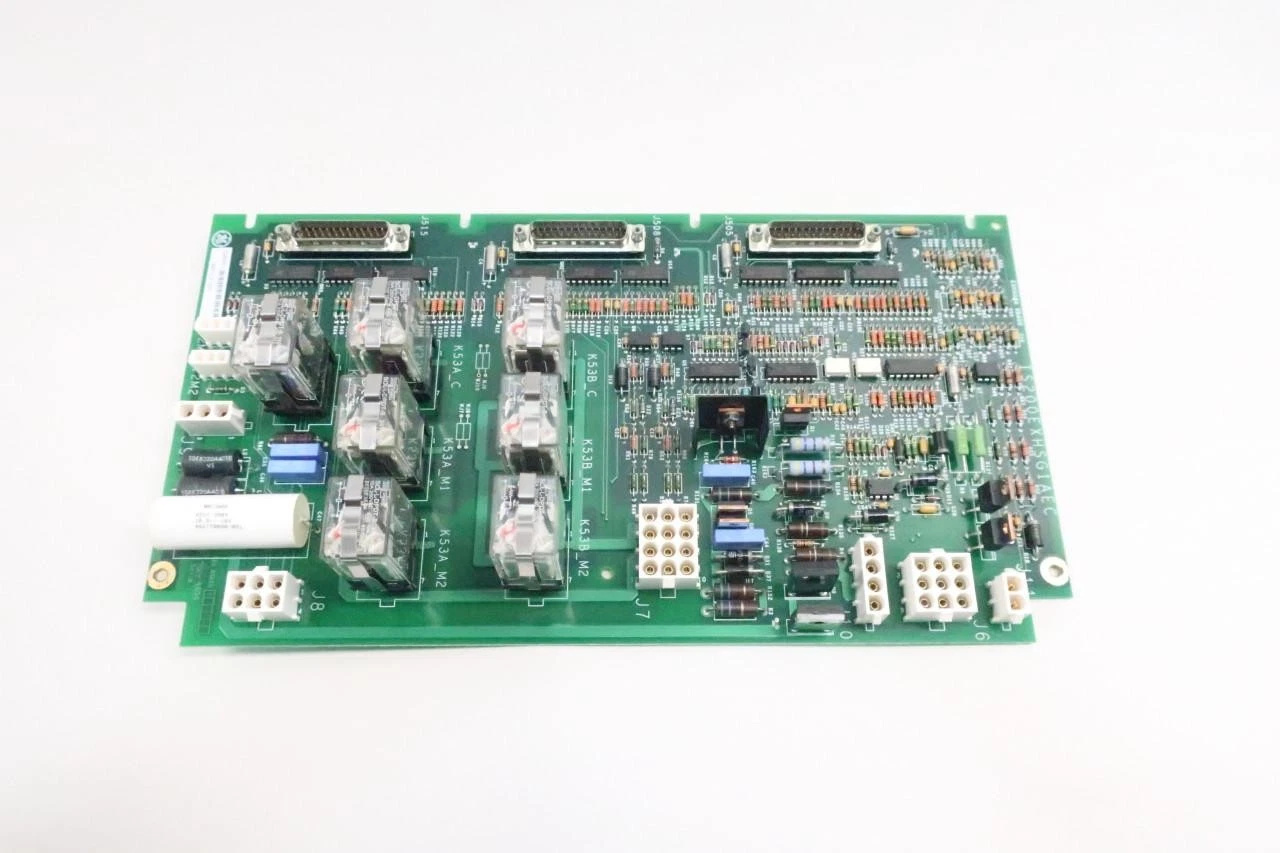

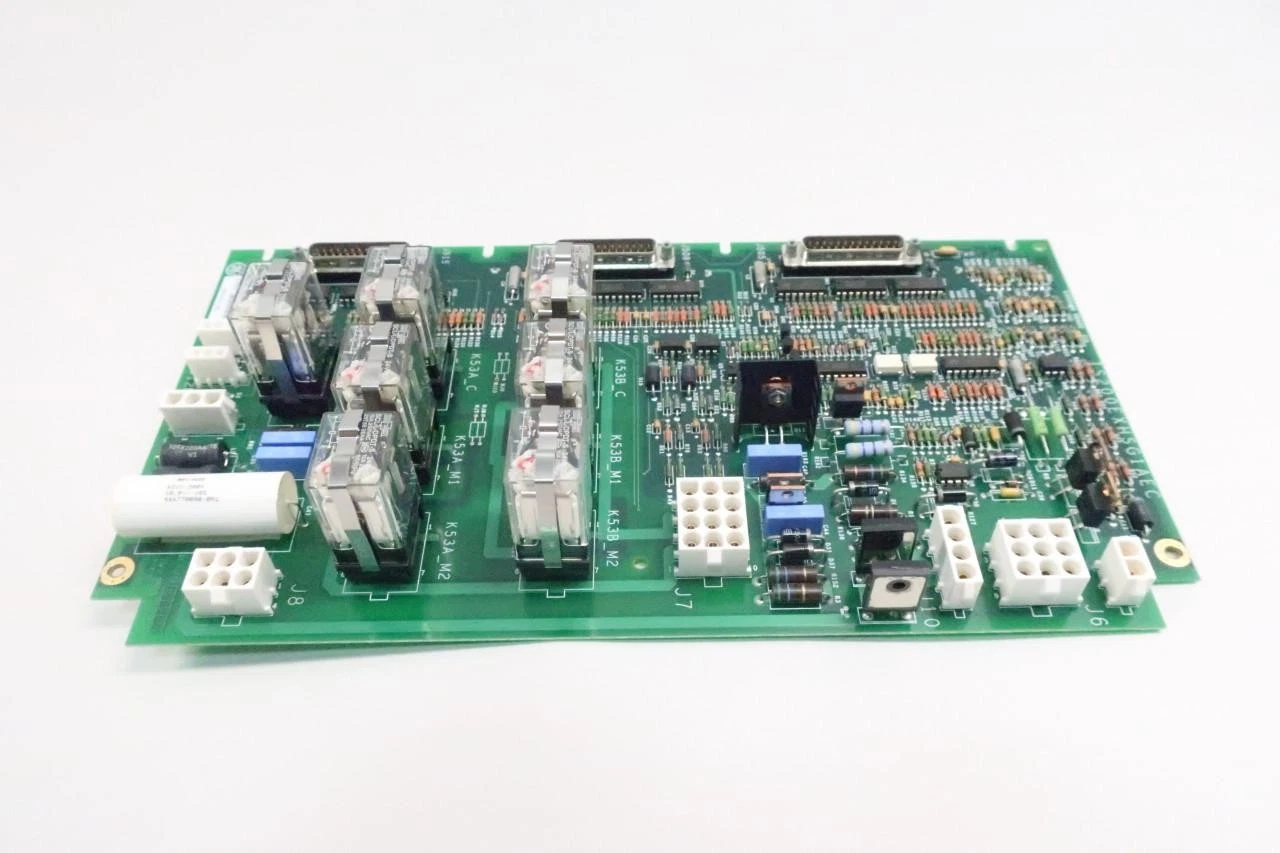

GE IS200EXHSG1AEC Relay Drive Board

GE IS200EXHSG1AEC

The GE IS200EXHSG1AEC is a high-speed exciter relay drive board under the GE Mark VI Speedtronic series. It belongs to the modular electronic components of the IS200 series, specifically designed for excitation control in steam turbines, generators, and other high-power industrial equipment. It enables fast and reliable switching operations in high-current environments.

Key Technical Specifications

- Operating Voltage: 24 V DC (power supply)

- Output Current: Capable of driving excitation current ranging from 100 A to 400 A

- Operating Temperature Range: -40 °C to +85 °C

- Protection Class: IP67 (dustproof and waterproof)

- Dimensions: Approximately 150 mm × 100 mm × 50 mm

- Weight: Approximately 1.5 kg to 2 kg

- Communication Interfaces: Ethernet, RS-485 (optional)

Product Features

- High-Speed Response: Tailored for fast switching in excitation systems, with an extremely short response time.

- Modular Design: The board can be used independently or configured for dual and triple redundancy in the Mark VI system to enhance system reliability.

- High Reliability: Adopts solid-state relays to drive DC contactors, featuring high current resistance and impact resistance.

- Multiple Communication Options: Supports industrial standard interfaces such as Ethernet and RS-485, facilitating remote monitoring and diagnosis.

- Easy Maintenance: Compact structure with plug-in connectors, enabling convenient on-site replacement and fault troubleshooting.

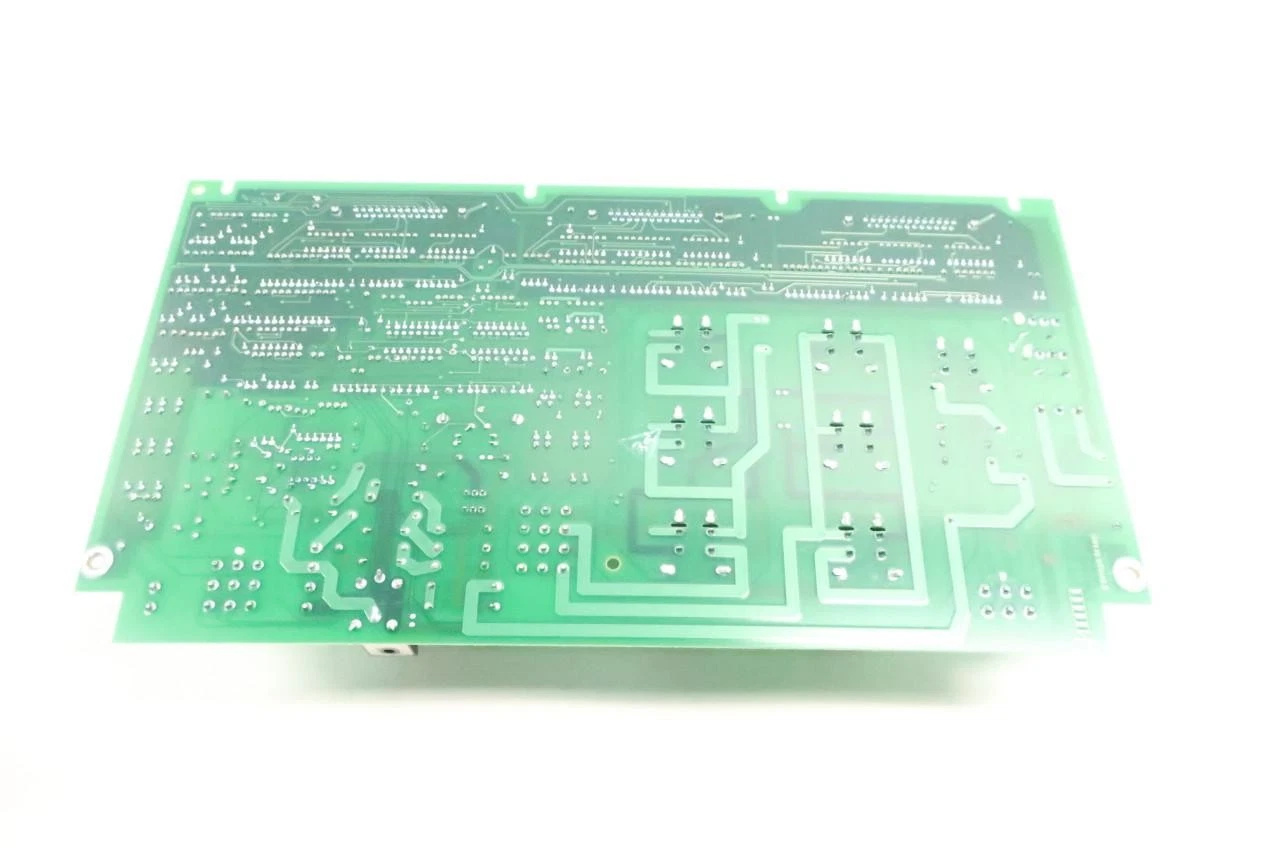

Structure and Composition

- Backplane (P1/P2): Communicates with the Exciter Module I/O (EMIO) board via backplane connectors.

- Power Drive Area: Includes solid-state relays, heat sinks, and power MOSFETs/IGBTs, responsible for high-current excitation output.

- Control Area: Consists of microprocessors, digital/analog I/O, and communication chips, enabling signal acquisition and command execution.

- Interface Area: Comprises D-shell cables, pins, and terminal blocks for wiring of power supplies, signals, and external devices.

Typical Application Fields

- Steam Turbine Excitation Control: Regulation and protection of excitation current in generator sets.

- Large-Scale Power Equipment: Excitation systems for synchronous generators and transformers, for example.

- High-Power Industrial Processes: Including oil, chemical, and metallurgical industries that require fast and reliable current driving.

- Other Automation Systems: Systems needing high-speed relay driving, such as large motor starting and power distribution.

Installation and Maintenance Guidelines

- Installation Environment: Ensure the operating temperature and humidity comply with the requirements of -40 °C to +85 °C and IP67 protection class. Avoid strong magnetic fields and strong vibrations.

- Power Wiring: Use cables that meet the rated current requirements and ensure a stable 24 V DC power supply.

- Backplane Connection: Align with the EMIO board via the P1/P2 backplane connectors and check if the pins are securely fastened.

- Heat Dissipation Management: Under high-load conditions, maintain good ventilation between the heat sinks and the chassis. Install additional fans if necessary.

- Communication Configuration: Configure Ethernet or RS-485 parameters (baud rate, address, etc.) based on on-site network selection, and map corresponding points in the HMI/SCADA system.

- Fault Diagnosis: The on-board self-test function reports the status of the power supply, communication, and relays during startup. Fault codes can be viewed via the HMI to locate problems.

- Regular Inspection: Check the tightness of connectors, the cleanliness of heat sink surfaces, and the operating temperature of solid-state relays every 6 to 12 months.

————————————————————————————————————-

If you would like to learn more about our products and services, please feel free to contact us at any time!

- Sales Manager : Jinny

- Email : sales5@xrjdcs.com

- Whatsapp/Mobile:+86 15359273791

Global renowned brand cooperation

ABB 丨 GE 丨Allen Bradley 丨 Honeywell 丨 Emerson 丨 Bently Nevada 丨 Westinghouse

Triconex 丨 Foxboro 丨 ICS Triplex 丨 Hima 丨 Schneider 丨 Yokogawa 丨 Woodward

—————————————————————————————

Backed by years of accumulated expertise in the industry, we stand out with distinct strengths in the industrial control field. Our offerings cover a wide range of products, supported by a stable supply chain, a team of professional technicians, and a fully optimized service system — all designed to address your operational needs effectively.

Frequently Asked Questions (FAQ)

Q1: When is the earliest you can ship the goods?

Q2: Do you have any overseas branches?

Q3: Are you a manufacturer or a trading company?

Q4: Is technical support available from your side?

Q5: Can you supply data sheets, documents, or technical literature?