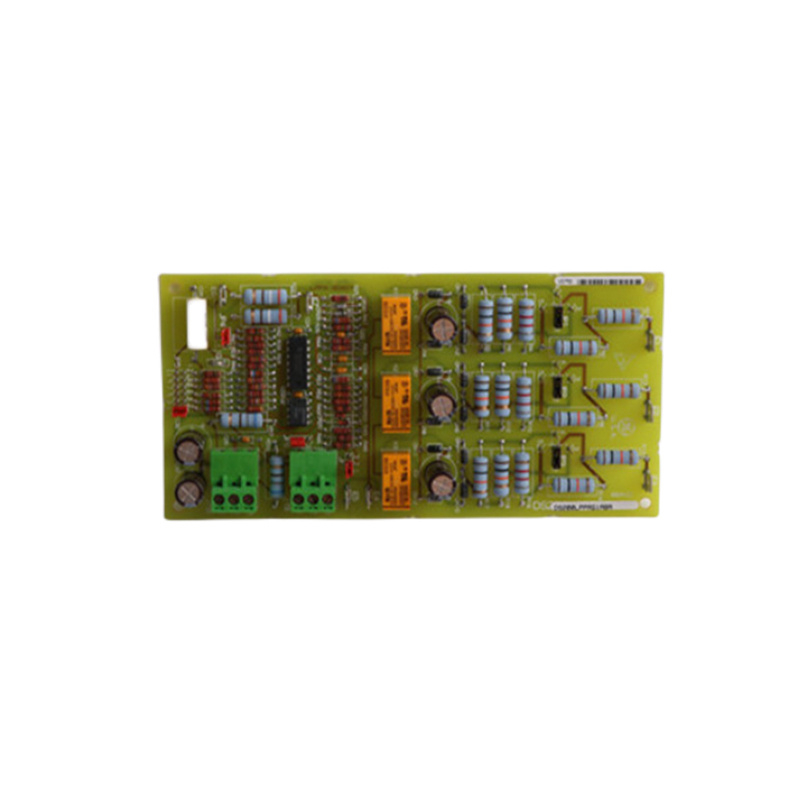

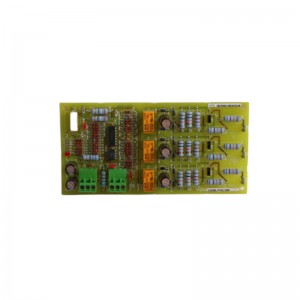

GE IS200RCSBG1B interface board

GE IS200RCSBG1B

The GE IS200RCSBG1B is a key component in the Mark VIe Gas Turbine Control System produced by GE Fanuc, a subsidiary of General Electric (GE). Specifically defined as a Remote Control Station Interface Board, this module embodies the core of the distributed I/O architecture of the GE Mark VIe platform. Serving as the main control module for remote I/O stations (such as PDIO packages), it is responsible for managing communication, data acquisition, and control output with all I/O modules within the station. The GE IS200RCSBG1B performs real-time data exchange with the central controllers (e.g., <EX2100> or <TX1500>) of the Mark VIe system via a high-speed Ethernet bus (such as the SRTP protocol). It uploads the collected on-site equipment data and sends instructions received from the controllers to the actuators.

Product Parameters

- Product Model: IS200RCSBG1B

- Manufacturer: General Electric (GE)

- Product Type: Remote I/O Station Communication Interface Board

- Associated System: Mark VIe Control System

- Main Communication Protocol: SRTP (Secure Real-Time Protocol) over Ethernet

- Backplane Communication Protocol: VME (VersaModule Eurocard)

- Supported I/O Module Types: Compatible with all Mark VIe series I/O modules of models D, T, A, etc.

- Operating Power Supply: +5V DC (provided by the on-station power module via the backplane)

- Operating Temperature: 0°C to 60°C (32°F to 140°F)

- Storage Temperature: -40°C to 85°C (-40°F to 185°F)

- Installation Method: Vertically installed in a Mark VIe dedicated rack or PDIO package

- Protection Level: Must be installed in a chassis with a protection level of IP52 or higher

Structure and Composition

Key Features and Advantages

- Core of Distributed Architecture: The GE IS200RCSBG1B is crucial for realizing the distributed I/O concept of the Mark VIe system. It allows I/O stations to be deployed close to on-site sensors and actuators, greatly shortening the transmission distance of analog signals, thereby reducing signal attenuation and electromagnetic interference, and improving the accuracy of data acquisition and system reliability.

- High Performance and High Reliability: The module adopts a powerful processor and a real-time operating system, enabling efficient processing of high-speed data from multiple I/O modules. Its dual Ethernet ports support redundant network configuration, ensuring that the communication link with the controller remains unobstructed in case of any single-point failure, meeting the highest requirements for continuous operation in gas turbine control.

- Powerful Diagnostic and Maintenance Functions: The digital display and multiple status LEDs integrated on the front panel of the module can provide rich diagnostic information. Technicians can quickly obtain key information such as station address, network status, and fault codes without connecting software tools, which greatly simplifies the troubleshooting process and shortens the Mean Time To Repair (MTTR).

- Excellent Compatibility and Scalability: The GE IS200RCSBG1B is fully compatible with all Mark VIe series I/O modules. Users can flexibly configure the type and quantity of modules in the station according to actual needs, easily realizing system expansion or modification, which protects the original investment and provides future-oriented flexibility.

Application Fields

Installation and Maintenance

- Preparation Before Installation: Before installing or replacing the GE IS200RCSBG1B module, it is essential to confirm that the system is completely powered off and the Lockout-Tagout (LOTO) procedure is implemented. Check whether the target rack slot and backplane connector are clean and free of physical damage. Confirm that the firmware version of the module is compatible with other components in the system (especially the controller). Prepare the required configuration files for configuring the module after installation.

- Maintenance Recommendations: Conduct regular inspections on the operating GE IS200RCSBG1B module. Observe whether the status indicators and display information on the front panel are normal and confirm that there are no alarm or fault codes. Keep the installation environment of the module and the ventilation holes clean to prevent dust accumulation from affecting heat dissipation. Before performing any maintenance operations, be sure to put the I/O station in a safe state (such as maintenance mode) through software tools to prevent accidental output. It is recommended to use GE’s dedicated ToolboxST software for in-depth diagnosis, module status monitoring, and firmware management.

————————————————————————————————————-

If you would like to learn more about our products and services, please feel free to contact us at any time!

- Sales Manager : Jinny

- Email : sales5@xrjdcs.com

- Whatsapp/Mobile:+86 15359273791

Global renowned brand cooperation

ABB 丨 GE 丨Allen Bradley 丨 Honeywell 丨 Emerson 丨 Bently Nevada 丨 Westinghouse

Triconex 丨 Foxboro 丨 ICS Triplex 丨 Hima 丨 Schneider 丨 Yokogawa 丨 Woodward

—————————————————————————————

Main Products, Advantageous Supply, Sufficient Inventory:

- DCS and PLC Spare Parts of Various Brands

- Invensys Foxboro: I/A Series systems, FBM (Field Input/Output Modules) for sequence control, ladder logic control, event recall processing, digital-to-analog conversion, input/output signal processing, data communication and processing, etc.

- Invensys Triconex: Redundant fault-tolerant control systems, and modern fault-tolerant controllers based on Triple Modular Redundancy (TMR) architecture.

- Westinghouse: Spare parts for OVATION systems, WDPF systems, and WEStation systems.

- Rockwell Allen-Bradley: Reliance, SLC500/1747/1746, MicroLogix/1761/1763/1762/1766/1764, CompactLogix/1769/1768, Logix5000/1756/1789/1794/1760/1788, PLC-5/1771/1785, etc.

- Schneider Modicon: Processors, control cards, power modules of the Quantum 140 series, etc.

- ABB: Industrial robot spare parts of the DSQC series, Bailey INFI 90, etc.

- Siemens: Siemens MOORE, Siemens Simatic C1, Siemens CNC systems, etc.

- Motorola: MVME 162, MVME 167, MVME 1772, MVME 177 series, etc.

- XYCOM: I/O modules, VME boards, processors, etc.

- GE FANUC: Various spare parts such as modules, cards, and drives.

- Yaskawa: Servo controllers, servo motors, servo drives.

- Bosch Rexroth: Indramat products, I/O modules, PLC controllers, drive modules, etc.

- Woodward: SPC valve position controllers, PEAK150 digital controllers.

- Industrial Robot System Spare Parts

- Advantageous Brands: ABB Robots, FANUC Robots, YASKAWA Robots, KUKA Robots, Mitsubishi Robots, OTC Robots, Panasonic Robots, MOTOMAN Robots, etc.