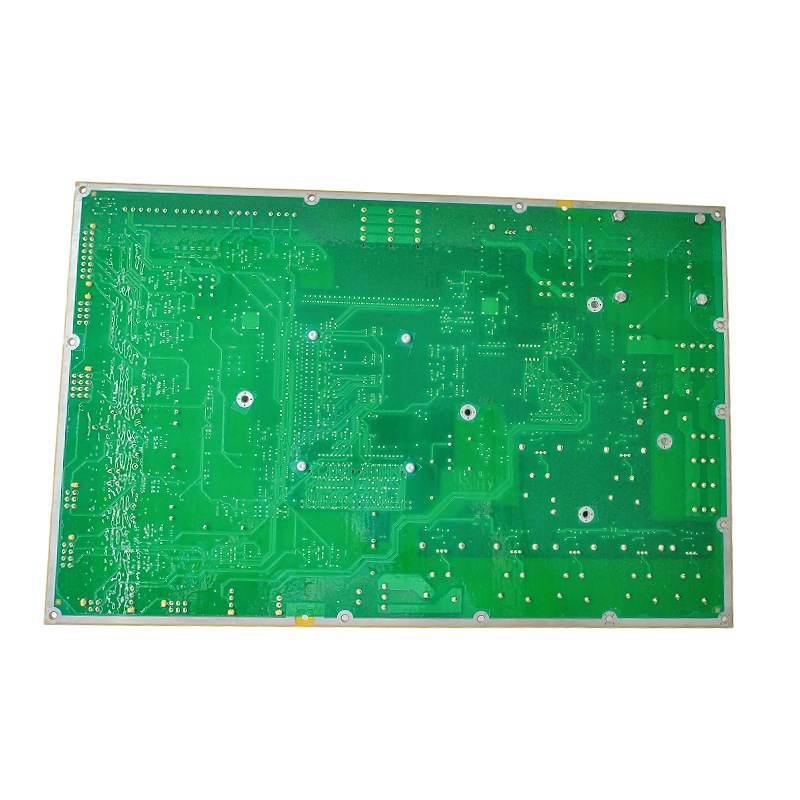

GE IS215WEMAH1A Input/Output Module

GE IS215WEMAH1A

GE IS215WEMAH1A is a key component in the Mark VI series gas turbine control system produced by GE Fanuc, a subsidiary of General Electric (GE). Specifically defined as a Water/Exhaust Monitor Analog I/O Module, it is a dedicated analog processing module for the GE Mark VI platform. Its primary function is to accurately collect and process critical sensor signals related to water circulation systems and exhaust gas emission monitoring (such as pH value, conductivity, turbidity, oxygen content, and NOₓ concentration). After processing, the data is transmitted to the system controller via the backplane bus. GE IS215WEMAH1A plays a vital role in ensuring environmental compliance and equipment protection within the system, guaranteeing that the gas turbine’s auxiliary systems operate within parameters that are both safe and environmentally friendly.

Product Specifications

- Product Model: IS215WEMAH1A

- Manufacturer: General Electric (GE)

- Product Type: Dedicated Analog Input/Output Module (Water/Exhaust Monitoring)

- Affiliated System: Mark VI Control System

- Backplane Communication: VME (VersaModule Eurocard)

- Input Signal Type: 4-20mA, 0-10V DC, Thermocouple, RTD (depending on configuration and terminal board)

- Output Signal Type: 4-20mA (for control or alarm)

- Number of Channels: Typically 8 analog inputs and 2 analog outputs (specific to configuration)

- Accuracy: ±0.1% F.S. (Full Scale) or higher

- Operating Power Supply: +5V DC (provided by the rack power module via the backplane)

- Operating Temperature: 0°C to 60°C (32°F to 140°F)

- Installation Method: Vertically installed in a Mark VI dedicated VME rack

Structure and Composition

Key Features and Advantages

-

High Precision and Dedicated Signal Processing: GE IS215WEMAH1A is optimized for the special signal requirements of water treatment and exhaust gas monitoring sensors. It incorporates high-precision ADCs and dedicated signal conditioning algorithms, enabling accurate measurement of various slowly changing process analysis signals. This ensures the reliability of monitoring data and provides data support for environmental compliance.

-

Strong Electrical Isolation and Anti-Interference Capability: Each input channel of the module typically adopts photoelectric or magnetoelectric isolation technology. This effectively prevents damage to the module caused by ground loops and high-voltage transient surges, while suppressing electromagnetic interference (EMI) in industrial environments—ensuring signal purity and system safety in harsh electrical environments.

-

Comprehensive Built-in Diagnostic Functions: The module features powerful self-diagnostic capabilities, capable of real-time monitoring of fault conditions such as channel open circuits, short circuits, and over-ranging. Fault information is immediately reported via the front-panel LEDs and system software. This predictive maintenance capability allows operation and maintenance personnel to quickly locate issues, significantly reducing downtime and improving unit availability.

-

Seamless System Integration: As a native component of the Mark VI system, GE IS215WEMAH1A can be seamlessly integrated with the <TXP> Controller, <EX2100> Excitation System, and software tools such as <CIMPLICITY> or <ToolboxST>. This enables unified configuration, monitoring, and maintenance, reducing engineering and maintenance costs throughout the entire lifecycle.

Application Fields

- Monitoring the pH value and conductivity of boiler feedwater and condensed water;

- Processing analyzer signals in Continuous Emission Monitoring Systems (CEMS) for measuring flue gas oxygen content, nitrogen oxide (NOₓ), and sulfur dioxide (SO₂) concentrations;

- Controlling related chemical dosing pumps.

————————————————————————————————————-

If you would like to learn more about our products and services, please feel free to contact us at any time!

- Sales Manager : Jinny

- Email : sales5@xrjdcs.com

- Whatsapp/Mobile:+86 15359273791

Global renowned brand cooperation

ABB 丨 GE 丨Allen Bradley 丨 Honeywell 丨 Emerson 丨 Bently Nevada 丨 Westinghouse

Triconex 丨 Foxboro 丨 ICS Triplex 丨 Hima 丨 Schneider 丨 Yokogawa 丨 Woodward

—————————————————————————————

Main Products, Advantageous Supply, Sufficient Inventory:

- DCS and PLC Spare Parts of Various Brands

- Invensys Foxboro: I/A Series systems, FBM (Field Input/Output Modules) for sequence control, ladder logic control, event recall processing, digital-to-analog conversion, input/output signal processing, data communication and processing, etc.

- Invensys Triconex: Redundant fault-tolerant control systems, and modern fault-tolerant controllers based on Triple Modular Redundancy (TMR) architecture.

- Westinghouse: Spare parts for OVATION systems, WDPF systems, and WEStation systems.

- Rockwell Allen-Bradley: Reliance, SLC500/1747/1746, MicroLogix/1761/1763/1762/1766/1764, CompactLogix/1769/1768, Logix5000/1756/1789/1794/1760/1788, PLC-5/1771/1785, etc.

- Schneider Modicon: Processors, control cards, power modules of the Quantum 140 series, etc.

- ABB: Industrial robot spare parts of the DSQC series, Bailey INFI 90, etc.

- Siemens: Siemens MOORE, Siemens Simatic C1, Siemens CNC systems, etc.

- Motorola: MVME 162, MVME 167, MVME 1772, MVME 177 series, etc.

- XYCOM: I/O modules, VME boards, processors, etc.

- GE FANUC: Various spare parts such as modules, cards, and drives.

- Yaskawa: Servo controllers, servo motors, servo drives.

- Bosch Rexroth: Indramat products, I/O modules, PLC controllers, drive modules, etc.

- Woodward: SPC valve position controllers, PEAK150 digital controllers.

- Industrial Robot System Spare Parts

- Advantageous Brands: ABB Robots, FANUC Robots, YASKAWA Robots, KUKA Robots, Mitsubishi Robots, OTC Robots, Panasonic Robots, MOTOMAN Robots, etc.