Welcome to our websites!

GE IS200TRLYH1B Terminal Relay Card

GE IS200TRLYH1B

1. Product Overview

The GE IS200TRLYH1B is a terminal relay card for the GE Mark VI steam turbine/gas turbine control system.As the “B” version of the TRLY terminal board, it provides 48 channels of Barrier relay outputs.It adopts technologies such as voting coil-driven feedback, socket-type sealed mechanical relays, and MOV suppression to ensure high reliability and anti-interference capability.

2. Key Technical Specifications

| Specification | Description |

|---|---|

| Model | IS200TRLYH1B (or variants including IS200TRLYH1B HH, BGF, etc.) |

| Number of Terminals | 48 channels (two terminal boards, 24 silver metal terminals each) |

| Power Supply | 24 V DC |

| Rated Current | 1 A / 2 A (5 A, 10 A optional) |

| Operating Temperature | –40 °C ~ +85 °C |

| Protection Class | IP67 (for BGF variant) |

| Dimensions | Approximately 120 mm × 80 mm × 40 mm |

| Weight | 0.2 ~ 0.5 kg |

| Connection Method | DIN rail mounting; spring clips or bolted wiring for terminals |

3. Product Features

- High Reliability: Multi-layer PCB, SMD components, and voting coil-driven feedback prevent single-point failures.

- Modular Design: Detachable terminal boards and optional pluggable mechanical relays facilitate on-site maintenance and replacement.

- Safety Protection: Built-in MOV suppression and overcurrent/overvoltage protection, complying with industrial safety standards such as IEC 61800‑9‑1.

- Strong Compatibility: Fully compatible with the I/O interface of the GE Mark VI control system, supporting 48-channel barrier outputs and adapting to various on-site equipment.

- Environmental Adaptability: Wide temperature range and IP67 protection make it suitable for harsh industrial sites.

4. Structure and Composition

- Two Terminal Boards: Two large black terminal boards on the left, with 24 silver terminals each, totaling 48 channels.

- Mechanical Relays: Socket-type sealed mechanical relays equipped with MOV suppression circuits.

- Voting Coil Drive Circuit: Enables redundant driving to improve reliability.

- Connectors: 4 connector ports on the right for communication with the control system host.

- Housing: Aluminum alloy or high-strength plastic, providing IP67 protection.

5. Typical Application Fields

- Gas/steam turbine control (Mark VI turbine system)

- Power systems: Relay protection and control in power plants and substations

- Petroleum and chemical industry: Process control, and start/stop of valves and pumps

- Industrial automation: I/O expansion for production lines, robots, and equipment manufacturing

- Energy management: Power distribution automation and load dispatching

6. Installation and Maintenance Points

| Step | Key Points |

|---|---|

| Hardware Installation | Insert the module into the corresponding Mark VI slot in the control cabinet and ensure the clip is locked securely. |

| Wiring | Connect the power supply and signal lines according to the wiring diagram; use spring clips or bolts to ensure firm connections, and comply with the IEC 60204‑1 electrical safety standard. |

| Configuration | Identify the module in the Mark VI control software, assign I/O addresses, and set the barrier logic. |

| Debugging | Check the on/off status of each relay and verify that the MOV suppression function works normally. |

| Regular Inspection | Inspect terminal tightness, housing protection, and heat dissipation every 6 ~ 12 months; replace faulty relays or terminal boards in a timely manner if abnormalities are found. |

| Spare Parts Management | It is recommended to keep terminal boards, mechanical relays, and MOV suppression diodes of the same model in stock to shorten maintenance downtime. |

————————————————————————————————————-

If you would like to learn more about our products and services, please feel free to contact us at any time!

- Sales Manager : Jinny

- Email : sales5@xrjdcs.com

- Whatsapp/Mobile:+86 15359273791

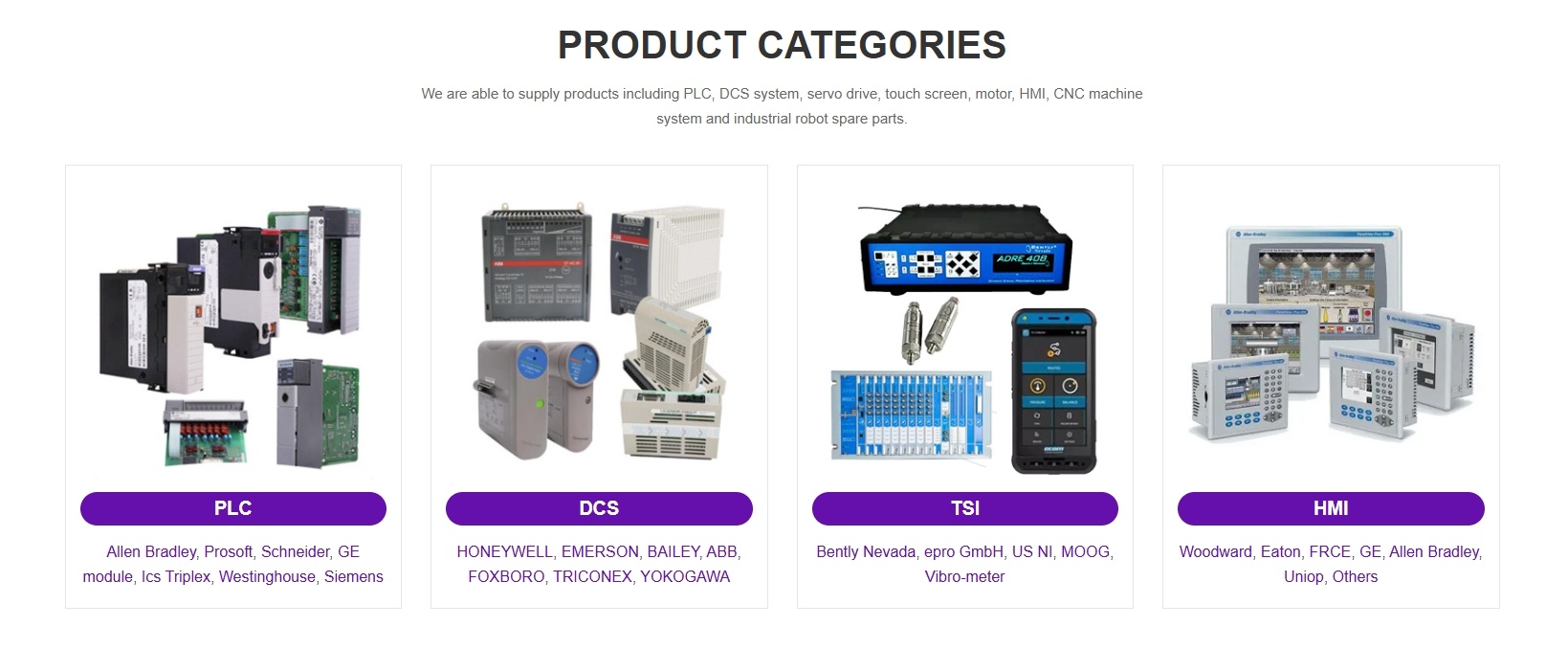

Global renowned brand cooperation

ABB 丨 GE 丨Allen Bradley 丨 Honeywell 丨 Emerson 丨 Bently Nevada 丨 Westinghouse

Triconex 丨 Foxboro 丨 ICS Triplex 丨 Hima 丨 Schneider 丨 Yokogawa 丨 Woodward

—————————————————————————————

Xiamen Xingruijia Import and Export Co., Ltd.

Ever since its founding, Xiamen Xingruijia Import and Export Co., Ltd. has sustained a stable growth trajectory. We keep expanding our product portfolio, boosting market share, and strengthening brand presence in the industry. Looking ahead, we will continue to uphold our business principle of “Prioritizing Customers, Rooting in Integrity” to deliver greater value to our clients.

About Logistics

- Geographical Edge: As a company based in Xiamen—a key port city—we leverage well-developed sea, air, and land transport networks to enable swift domestic and international cargo movement, effectively cutting down delivery cycles.

- Global Logistics Connections: Through partnerships with world-renowned logistics providers, we offer a variety of transportation options, including ocean freight and air cargo services, guaranteeing that goods reach destinations worldwide safely and efficiently.

- Customizable Transportation Solutions: Tailored to meet specific customer requirements, we provide services such as door-to-door delivery, less than container load (LCL) shipping, and full container load (FCL) shipping. These solutions help clients lower operational costs and enhance overall efficiency.

- Real-Time Cargo Tracking: We provide real-time tracking functionality for shipped goods, allowing customers to monitor the transportation status at any moment and ensuring that deliveries arrive as scheduled.

- Professional Customs Clearance Services: Our team offers fast customs declaration procedures and professional tariff consultation, facilitating smooth customs clearance for international shipments and minimizing potential delays.

- Premium Packaging Standards: We use internationally compliant packaging materials to ensure that goods remain intact throughout the transportation process. Additionally, we offer customized packaging solutions to meet unique customer needs.

Write your message here and send it to us