Welcome to our websites!

GE IS200VCMIH1B IS200VCMIH1BCB Controller

GE IS200VCMIH1B IS200VCMIH1BCB

The GE IS200VCMI series is a Bus Master Controller (VCMI Communication Board) specifically designed for the Mark VI control system. It enables high-speed and reliable communication between I/O boards and the main controller. Both IS200VCMIH1B and IS200VCMIH1BCB belong to this series, with differences only in hardware configuration and functional details.

Key Technical Specifications

- Processor: Adopts Texas Instruments TMS320C32 DSP, featuring real-time signal processing capability.

- Power Supply: 125 V DC (some documents indicate 24 V DC, depending on the power adapter of the specific model).

- Operating Temperature: -40 °C ~ +70 °C (0 °C ~ 45 °C for some models), suitable for harsh industrial site environments.

- Humidity Range: 5% ~ 95% (non-condensing).

- Interfaces:Communication Features: Supports SIFT (Software Implemented Fault Tolerance) voting fault tolerance, watchdog timer, and power monitoring functions.

- The front panel is equipped with a 9-pin serial port, a DIN connector, and multiple groups of LED indicators (RUN, FAIL, STATUS, etc.).

- Two backplane connectors are used for VME backplane slots.

- Dimensions & Weight: Approximately 2 pounds (about 0.9 kg), compatible with standard VME racks (13-slot or 21-slot).

Product Features

- High Reliability: Hardware watchdog, power supply monitoring, and fault-tolerant voting mechanisms ensure continuous operation in critical power plants or industrial sites.

- Modular Design: Front-panel LEDs and a reset switch facilitate quick on-site diagnosis; the backplane supports plug-and-play and multi-rack expansion.

- Multi-Protocol Compatibility: Can communicate with upper-level systems or on-site devices via protocols such as RS-485, Modbus, Ethernet/IP, and Profibus (specific protocols depend on upper-level software configuration).

- Easy Maintenance: Front-panel LEDs intuitively display operating status and support remote diagnosis; the modular structure simplifies replacement or upgrading.

- Wide Application Range: Widely used in process control and turbine control systems in industries such as power generation, oil and gas, iron and steel, papermaking, and chemical engineering.

Structure & Composition

- Front Panel: LED indicators (RUN, FAIL, STATUS), reset switch, 9-pin serial port, two rows of module indicators (R, S, T), and a DIN connector.

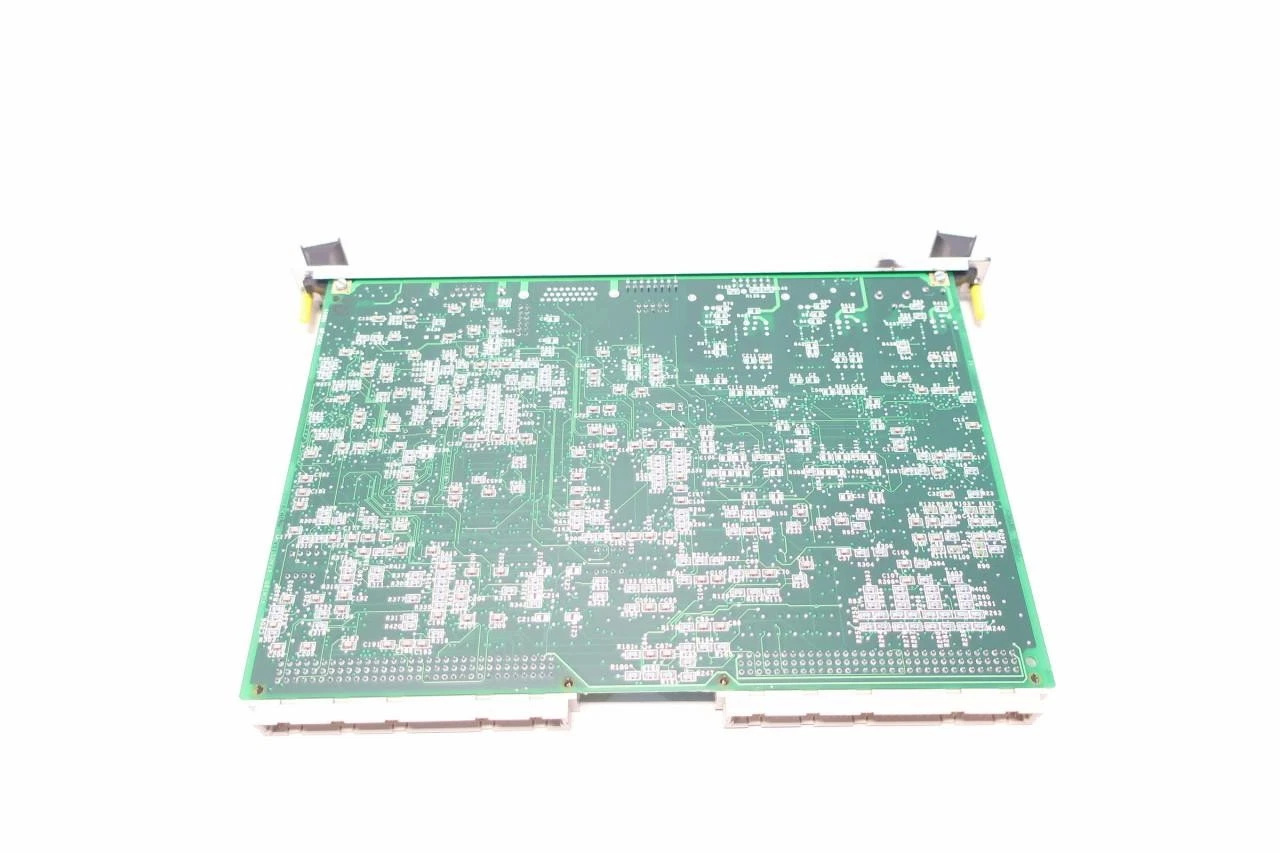

- Main Circuit Board: DSP processor, parallel port, watchdog timer, power monitoring chip, and communication interface circuit.

- Backplane Connectors: Two groups of VME backplane slots for connecting to the high-speed data bus of the rack backplane.

Typical Application Fields

- Power plant turbine control (core component of the Mark VI IS200 series)

- Oil and gas production process automation

- Real-time monitoring of iron and steel, papermaking, and chemical production lines

- Distributed I/O networks for large-scale manufacturing and water treatment systems

Installation & Maintenance Points

- Installation Position: Insert the module into slot 1 (or the corresponding empty slot) of the VME rack, ensuring the backplane connector is aligned with the rack backplane.

- Power Connection: Confirm that the power supply voltage meets the module specifications (125 V DC or 24 V DC), and check power filtering and grounding.

- Wiring Inspection: Ensure the front-panel serial port, DIN connector, and backplane slots are firmly connected to avoid communication interruption caused by looseness.

- Status Indication: After power-on, observe the LED indicators. A green RUN light indicates normal operation, a red FAIL light indicates a fault, and a yellow STATUS light provides warning information.

- Regular Diagnosis: Use the diagnostic software provided by GE to read the internal status of the module (watchdog count, power monitoring value) and perform firmware upgrades if necessary.

- Replacement & Spare Parts: The module is small in size and light in weight, allowing for quick on-site replacement; it is recommended to prepare spare parts of the same model for hot backup or quick recovery.

————————————————————————————————————-

If you would like to learn more about our products and services, please feel free to contact us at any time!

- Sales Manager : Jinny

- Email : sales5@xrjdcs.com

- Whatsapp/Mobile:+86 15359273791

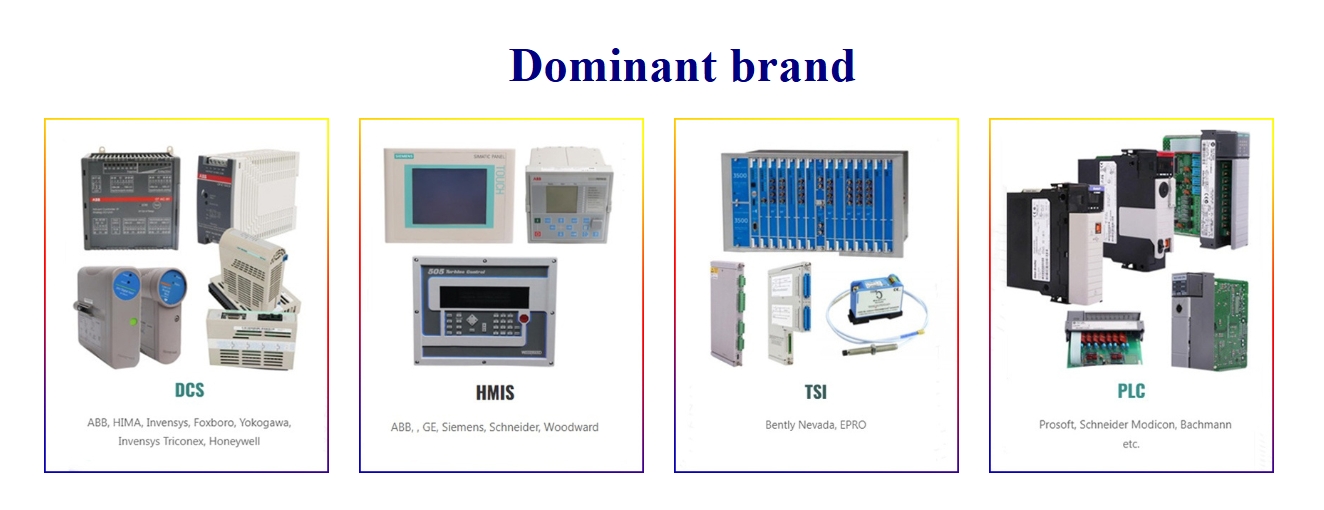

Global renowned brand cooperation

ABB 丨 GE 丨Allen Bradley 丨 Honeywell 丨 Emerson 丨 Bently Nevada 丨 Westinghouse

Triconex 丨 Foxboro 丨 ICS Triplex 丨 Hima 丨 Schneider 丨 Yokogawa 丨 Woodward

—————————————————————————————

Backed by years of accumulated expertise in the industry, we stand out with distinct strengths in the industrial control field. Our offerings cover a wide range of products, supported by a stable supply chain, a team of professional technicians, and a fully optimized service system — all designed to address your operational needs effectively.

Whether you require standard products or tailored solutions, we consistently deliver efficient and reliable support to keep your operations running smoothly. What’s more, we provide competitive pricing and maintain a large inventory of PLCs, including spare parts for leading brands such as GE Fanuc PLC, Schneider PLC, ABB DCS, and Yokogawa DCS.

Frequently Asked Questions (FAQ)

Q1: When is the earliest you can ship the goods?

A1: Shipment will be arranged promptly upon receipt of your payment.

Q2: Do you have any overseas branches?

A2: While we don’t have overseas branches, our products are distributed to customers across the globe.

Q3: Are you a manufacturer or a trading company?

A3: We operate as a trading company.

Q4: Is technical support available from your side?

A4: Currently, we focus on hardware sales and do not provide technical support services.

Q5: Can you supply data sheets, documents, or technical literature?

A5: Data sheets will be included in the delivery package along with your ordered goods.

Write your message here and send it to us