GE IS200VVIBH1C Vibration Monitoring Card

GE IS200VVIBH1C

The IS200VVIBH1C is a Vibration Monitoring Card (VMC) in the General Electric (GE) Mark Ⅵ series. It is specifically designed for health monitoring of steam turbines, gas turbines, and other rotating machinery. By collecting signals from vibration probes such as TVIB and DVIB, it performs digital processing of parameters including vibration amplitude, frequency, and phase, providing data support for subsequent fault diagnosis and early warning.

Main Technical Specifications

- Model/Series: IS200VVIBH1C, part of the GE Mark Ⅵ (Speedtronic) system.

- Input Channels: Up to 14 vibration probes.

- Supported Probe Types: Various vibration sensors including accelerometers, velocity meters, displacement meters, and proximity sensors.

- Input Voltage Range: -20 V ~ +20 V (±20 V).

- Input Impedance: 100 kΩ, with 16-bit resolution and a maximum sampling rate of approximately 4,600 samples/s.

- Operating Temperature: -40 °C ~ +85 °C; Storage Temperature: -55 °C ~ +90 °C.

- Power Supply: -24 V DC (power consumption approximately 20 W).

- Interface: VME (6U) card, compatible with the PC-HMI and control software of the Mark Ⅵ system.

Product Features

- High-Precision Measurement: Adopts low-noise pre-amplification and programmable filtering to achieve accurate capture of micro-vibrations.

- Multi-Channel & Flexible Configuration: Can connect to 14 (or 16) probes at one time, supports different probe types, and parameters can be freely set via software.

- Modular & Redundant Design: Complies with the Triple Modular Redundancy (TMR) architecture of Mark Ⅵ, improving system reliability and facilitating quick replacement and maintenance.

- In-Depth Integration with Upper-Level Computers: The collected digital signals are directly transmitted to the Mark Ⅵ control system, supporting real-time trend analysis, spectrum analysis, waveform analysis, and threshold alarming.

- Easy Installation: Features a standard VME card size for plug-and-play use. Equipped with LED indicators to display operation/fault/status, enabling quick on-site diagnosis.

Structure and Composition

- Front Panel: LED indicators (for operation, fault, and status), and connectors P1 and P2 for signal input.

- Internal Circuitry: Includes pre-amplifiers, filters, 16-bit analog-to-digital converters (ADCs), and FPGA/RAM for high-speed data processing.

- Heat Dissipation & Power Module: Two heat sinks, power capacitors, and protective fuses to ensure stable operation in high-temperature environments.

- Chassis: Complies with the VME 6U standard, with dimensions approximately 105 mm × 45 mm × 25 mm.

Typical Application Fields

- Power Industry: Vibration monitoring and early warning for steam turbines, gas turbines, and generator sets.

- Petrochemical Industry: Key rotating equipment such as pumps, compressors, and heat exchangers.

- Manufacturing Industry: Health assessment for large fans, centrifuges, and bearing systems.

- Heavy Industries (Steel, Papermaking, Cement, etc.): Trend analysis of long-term operating conditions for high-load machinery.

Installation and Maintenance Points

Pre-Installation Preparation

- Confirm that the cabinet has VME 6U slots, a power supply (-24 V DC), and an appropriate heat dissipation channel.

Mechanical Installation

- Insert the card into the VME slot, ensure the connector on the back of the card aligns with the cabinet backplane, and tighten the fixing screws.

Wiring

- Use a TVIB/DVIB junction box that meets specifications to connect the signal wires of vibration probes to the P1 and P2 interfaces of the card respectively. Ensure good shielding of signal wires to avoid electromagnetic interference.

Software Configuration

- Identify the card number in the Mark Ⅵ HMI software, and set the range, sampling rate, and threshold alarm parameters for each channel.

Function Verification

- After power-on, check the LED indicators. Use the HMI to perform a self-test (a “OK” message will be displayed if the self-test passes), and calibrate the signals of the connected probes.

Daily Maintenance

- Regularly check whether the card’s heat sinks are dusty and clean them if necessary.

- Perform a function self-test every six months to confirm normal sampling and digitization of all channels.

- If the fault indicator lights up, locate the faulty module (such as the pre-amplifier, ADC, or power supply) based on the HMI error information. Replace the entire card or the corresponding electronic components if necessary.

————————————————————————————————————-

If you would like to learn more about our products and services, please feel free to contact us at any time!

- Sales Manager : Jinny

- Email : sales5@xrjdcs.com

- Whatsapp/Mobile:+86 15359273791

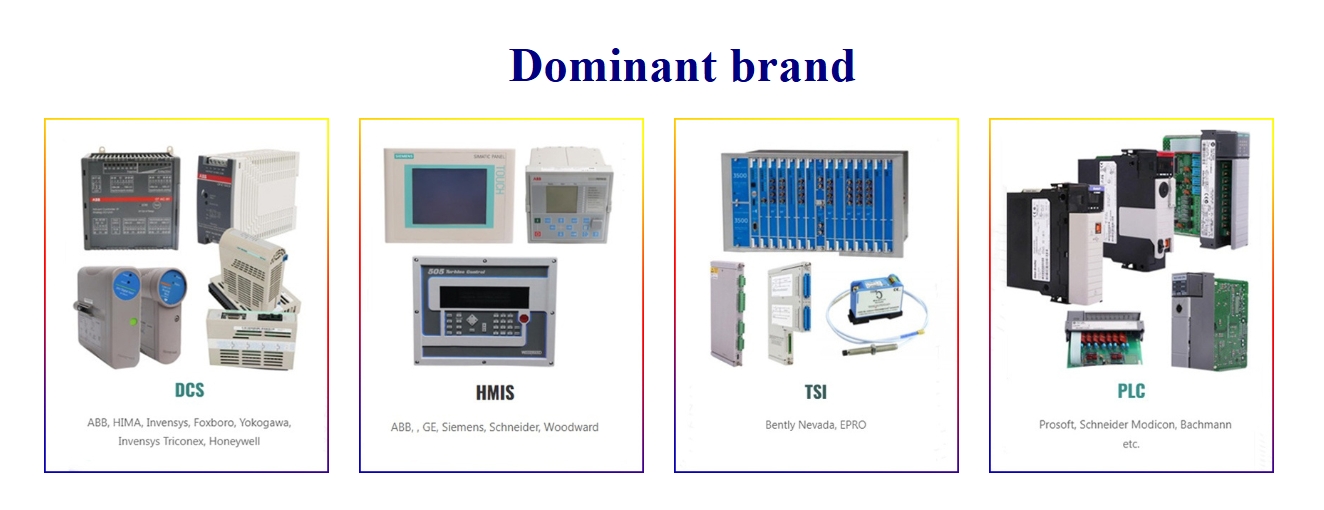

Global renowned brand cooperation

ABB 丨 GE 丨Allen Bradley 丨 Honeywell 丨 Emerson 丨 Bently Nevada 丨 Westinghouse

Triconex 丨 Foxboro 丨 ICS Triplex 丨 Hima 丨 Schneider 丨 Yokogawa 丨 Woodward

—————————————————————————————

Backed by years of accumulated expertise in the industry, we stand out with distinct strengths in the industrial control field. Our offerings cover a wide range of products, supported by a stable supply chain, a team of professional technicians, and a fully optimized service system — all designed to address your operational needs effectively.

Frequently Asked Questions (FAQ)

Q1: When is the earliest you can ship the goods?

Q2: Do you have any overseas branches?

Q3: Are you a manufacturer or a trading company?

Q4: Is technical support available from your side?

Q5: Can you supply data sheets, documents, or technical literature?