Welcome to our websites!

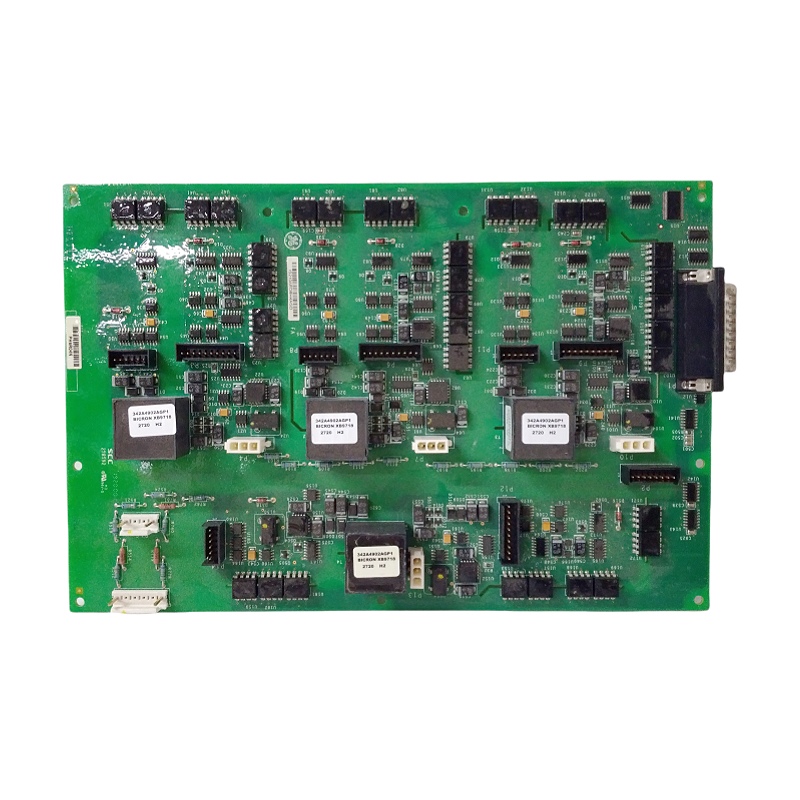

GE IS210WSVOH1AE servo valve control module

GE IS210WSVOH1AE

The GE IS210WSVOH1AE is a servo valve control module under the General Electric (GE) Mark VIe Speedtronic™ series. It is specifically designed for hydraulic actuators in large rotating machinery such as gas turbines and steam turbines. This module drives electro-hydraulic servo valves (e.g., MOOG valves) via high-precision current output, enabling precise control of critical actuators like fuel valves and guide vane angles. This ensures the stability and response speed of the unit under rapid load changes.

Core Values of IS210WSVOH1AE

- High-Precision Control: Features ±0.1% output accuracy, meeting the mA-level driving requirements of servo valves.

- Real-Time Feedback: Integrates sensor signal acquisition to achieve closed-loop control of valve positions.

- Redundancy and Fault Tolerance: Supports dual-module redundancy configuration to enhance system reliability.

Product Specifications

- Product Model: IS210WSVOH1AE

- Manufacturer: General Electric (GE)

- Product Type: Servo Valve Control Module

- Compatible System: GE Mark VIe Turbine Control Platform

- Output Channels: 2 channels (independent or redundant mode)

- Output Signal: 4-20mA (for driving servo valve coils)

- Output Accuracy: ±0.1% FS

- Load Capacity: ≤500Ω (per channel)

- Feedback Input: LVDT/RVDT (valve position sensor signals)

- Communication Interface: Interacts with the controller via the Mark VIe backplane

- Operating Temperature Range: -30°C to +70°C (-22°F to +158°F)

- Protection Class: IP20 (must be installed in a control cabinet)

- Installation Method: Inserted into the Mark VIe rack, occupying 1 slot

- Power Requirement: +24V DC (powered by the backplane)

- Certification Standards: IEC 60068, UL 508

Structure and Composition

The IS210WSVOH1AE adopts a modular design, with key components including:

- D/A Conversion Circuit: Equipped with a 16-bit high-precision digital-to-analog converter to generate 4-20mA servo valve driving signals.

- LVDT/RVDT Conditioning Circuit: A demodulator converts the sensor’s AC signal into DC position feedback (±10V).

- PID Control Unit: Calculates valve position deviations in real time and adjusts the output current (adjustment cycle ≤1ms).

- Redundancy Management Logic: Monitors the health status between dual modules and automatically switches faulty channels.

- Backplane Interface: A high-speed connector communicates with the Mark VIe backplane to receive controller commands.

- Status Indicator Lights: LEDs display output status and fault alarms (e.g., open circuit, short circuit).

Key Features and Advantages

-

High-Precision Servo Driving

- 16-bit resolution output ensures micron-level positioning accuracy of servo valves.

- LVDT/RVDT feedback compensation eliminates the impact of temperature drift on valve position measurement.

-

Redundant Reliability

- Supports Active-Standby mode, with a switching time ≤50ms.

- Automatically isolates faulty modules without affecting system operation.

-

Intelligent Diagnostic Function

- Real-time monitors the impedance of servo valve coils (to detect wire breaks or short circuits).

- Records historical faults (e.g., overcurrent count) via ToolboxST software.

-

Industrial-Grade Durability

- Wide operating temperature range of -30°C to +70°C, adapting to the environment of gas turbine control cabinets.

- Complies with the IEC 60068 vibration standard (5g @ 100Hz).

Typical Application Case

In gas turbines, the IS210WSVOH1AE drives the MOOG J761 servo valve. It adjusts fuel flow in real time based on speed deviations to maintain the rated speed of 3000 RPM.

Installation and Maintenance

Installation Key Points

- Perform operations with power off (or confirm the system supports hot swapping).

- Use twisted shielded wires for servo valve coil wires, with the shield grounded at one end.

- Ensure the LVDT/RVDT excitation frequency matches the module settings (usually 3kHz).

Maintenance Recommendations

- Monthly check the consistency between the output current and the actual valve position (calibrate with a multimeter).

- Regularly clean the module slot to prevent poor contact.

————————————————————————————————————-

If you would like to learn more about our products and services, please feel free to contact us at any time!

- Sales Manager : Jinny

- Email : sales5@xrjdcs.com

- Whatsapp/Mobile:+86 15359273791

Global renowned brand cooperation

ABB 丨 GE 丨Allen Bradley 丨 Honeywell 丨 Emerson 丨 Bently Nevada 丨 Westinghouse

Triconex 丨 Foxboro 丨 ICS Triplex 丨 Hima 丨 Schneider 丨 Yokogawa 丨 Woodward

—————————————————————————————

Industrial Automation: Components & Tailored Solutions

We specialize in supplying critical components for industrial automation systems, with a product portfolio designed to meet diverse operational needs:

- Distributed Control Systems (DCS) – for large-scale process control scenarios

- Programmable Logic Controllers (PLC) – core for discrete manufacturing automation

- MOTOROLA MVME Industrial Modules – reliable support for legacy industrial setups

- Anybus Industrial Communication Converters – enabling seamless cross-protocol communication

- Remote I/O Modules (RTU) – ideal for distributed field data acquisition

- Industrial PCs (IPC) – rugged computing solutions for harsh industrial environments

- Industrial Low-Frequency Screens – high-stability displays for 24/7 operation

- HMI SCSI Interfaces (50, 68, 80 Pin) – ensuring compatible HMI connectivity

- AnyBus Gateways – bridging gaps between different industrial networks

Whether your requirement is new original spare parts or hard-to-find obsolete/discontinued automation components, our team – backed by decades of frontline industry experience – delivers targeted solutions to minimize your operational downtime.

With direct overseas sourcing capabilities, we offer equipment and spares from global manufacturers across regions. This not only saves you the trouble of multi-channel procurement but also guarantees product authenticity and quality. We also stand out with competitive pricing. For detailed specs or customized queries, feel free to contact us via phone or email – we’re ready to assist.

What Makes Us Your Trusted Partner?

Global-Class Inventory Readiness

- We hold one of the industry’s most comprehensive inventories of automation spares, covering PLCs, DCS, drives, HMIs, and more. No matter your equipment’s brand or age, we ensure quick access to the parts you need – no long waits.

Engineer-Led Technical Support

- Our team isn’t just sales-focused – it’s made up of engineers with hands-on experience in industrial control systems. From troubleshooting hardware malfunctions to guiding software upgrades, we provide actionable, on-site-level support remotely.

Needs-Driven Custom Services

- We don’t just supply parts – we solve problems. Beyond standard spares, we offer customized services like old equipment repair, system retrofitting (to extend equipment lifespan), and on-site technical training for your team.

Global Reach, Local Response

- Our worldwide service network means we can coordinate sourcing and delivery from regional hubs, cutting down lead times. Wherever your facility is, you get the same fast, reliable service as local suppliers.

Obsolete Parts Specialists

- For discontinued or end-of-life components – a pain point for many factories – we have dedicated sourcing channels. We track hard-to-find parts globally, ensuring your legacy systems keep running.

Service That Puts You First

- Every interaction is guided by one goal: your operational efficiency. We prioritize transparency (no hidden costs), on-time delivery, and post-sales follow-up – making sure your needs are met at every step.

Write your message here and send it to us