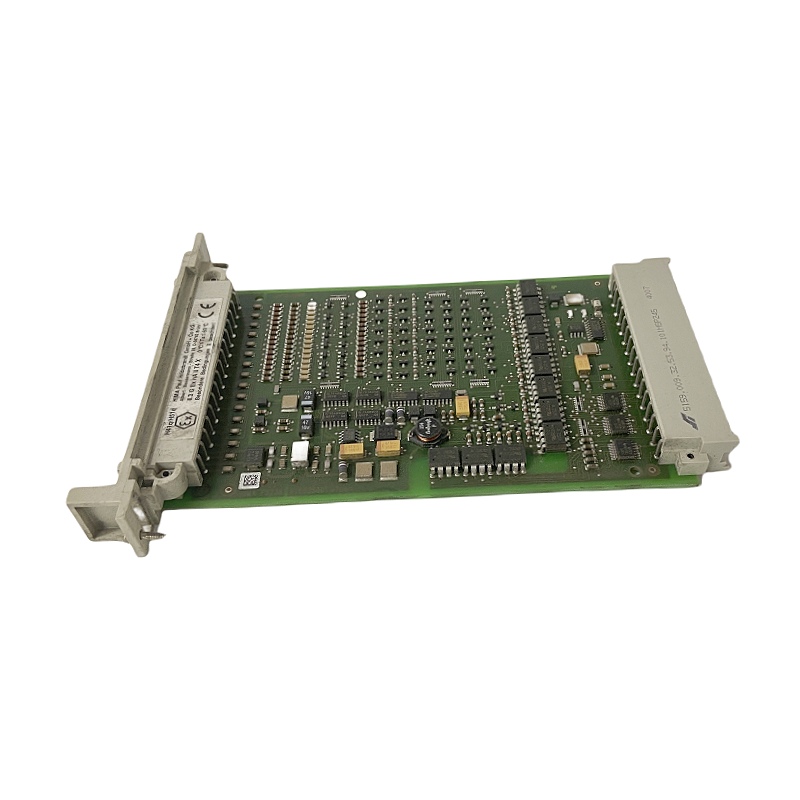

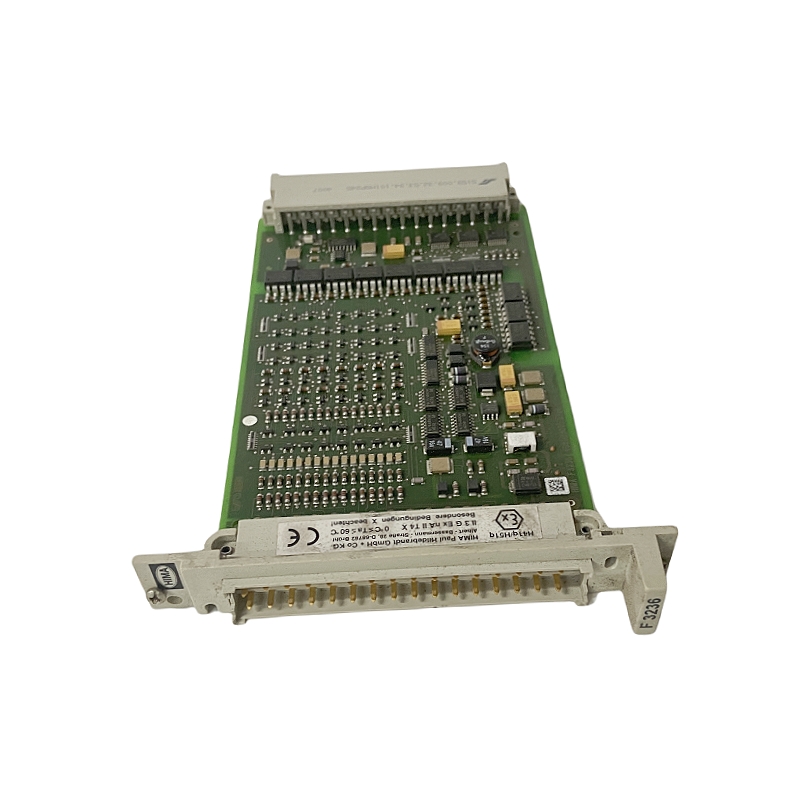

HIMA F3231 Digital Input Module

HIMA F3231

HIMA F3231 is a high-performance digital input module in the HIMA safety control system series, specifically designed to collect digital signals such as switching values and pulses from on-site equipment. It can convert these signals into safety signals recognizable by the safety control system, enabling real-time monitoring and safety interlocking of process equipment. Its modular structure, industrial-grade reliability, and compliance with multiple safety standards allow it to operate stably for a long time in harsh industrial environments.

Main Technical Parameters

- Power Supply Voltage: 24 V DC

- Operating Temperature Range: -20 ℃ ~ +60 ℃

- Relative Humidity: 5% ~ 95% RH (non-condensing)

- Input Channels: The number of digital input channels depends on the specific sub-module configuration, supporting multiple channels of switching values or pulse signals

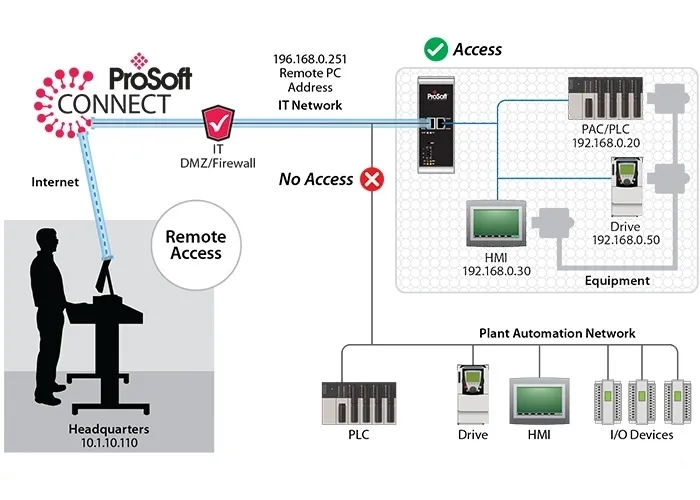

- Communication Interface: Compatible with HIMA system internal buses (such as PROFIBUS, PROFINET, etc.), enabling high-speed data exchange with safety controllers

- Safety Certifications: Complies with safety integrity level (SIL 3) requirements such as IEC 61508, EN 62061, IEC 61511, and holds CE certification

Product Features

- High Reliability: Adopts industrial-grade components and protective design, capable of stable operation in harsh environments such as high temperature, low temperature, and humidity.

- Rich Functions: Supports multiple digital signal types (switching values, pulses, counting, etc.), and allows flexible configuration of input filtering, debouncing, and other parameters through software.

- Modular Design: Uses standard DIN rail mounting dimensions, facilitating quick plugging and unplugging in the rack, and simplifying replacement and maintenance.

- Strong Safety: Meets SIL 3 level safety integrity requirements, with fault detection, dual-channel redundancy, and self-test functions to ensure the system remains in a safe state even when a fault occurs.

- Easy Integration: Achieves seamless connection with other HIMA safety control modules (such as CPU, output modules) and supports a unified engineering configuration tool.

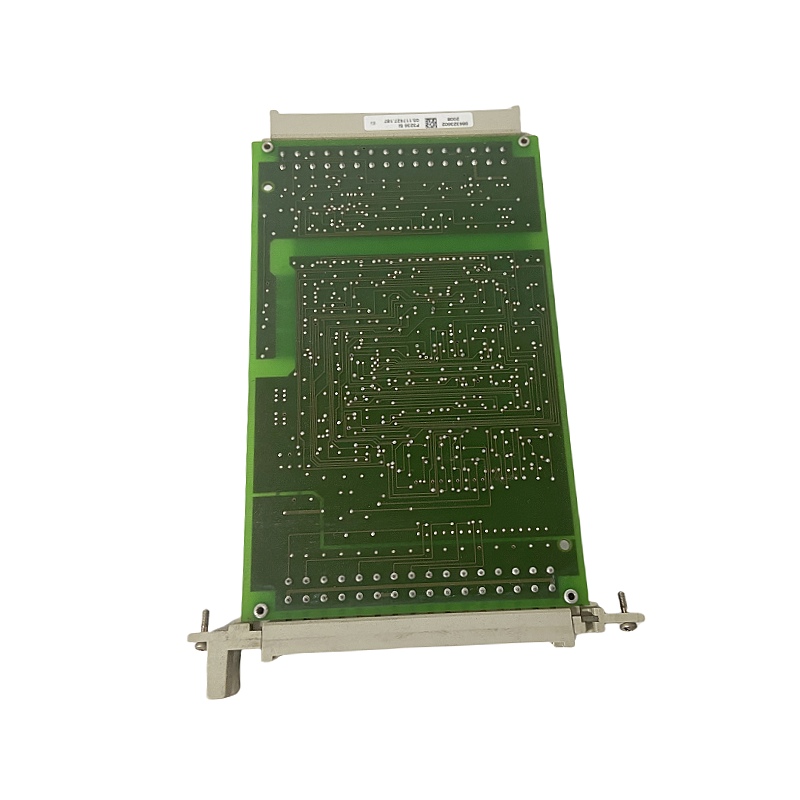

Structure and Composition

- Chassis: Metal shell, conforming to DIN rail standards, providing dust and water protection.

- Power Module: Internal 24 V DC power supply, with overvoltage and overcurrent protection.

- Digital Input Sub-module: Each sub-module contains several input channels, with isolation circuits, filter circuits, and fault detection circuits inside.

- Communication Interface Board: Responsible for bus communication with the upper-level safety controller, supporting multiple industrial network protocols.

- Status Indicator Lights: Used to display power, communication, and fault status, facilitating quick on-site diagnosis.

Typical Application Fields

- Chemical, Petroleum, Natural Gas: Safety interlocking, emergency shutdown, process monitoring.

- Electric Power, Power Plants: Unit protection, valve control, relay protection.

- Metallurgy, Iron and Steel: High-temperature furnace safety monitoring, conveyor system interlocking.

- Pharmaceutical, Food: Clean area safety control, key process parameter monitoring.

- Other High-Risk Industries: Any process control system that requires SIL 3 level safety integrity.

Installation and Maintenance Points

Installation

- Fix the module in a DIN rail cabinet that meets the IEC 60204-1 standard, ensuring the cabinet is well grounded.

- When connecting the 24 V DC power supply, check the polarity and use cables that meet the specifications to avoid damage to the module caused by power fluctuations.

- Connect the module to the HIMA safety controller through the corresponding industrial bus (such as PROFIBUS), ensuring the communication cables meet the shielding requirements.

Wiring

- Use shielded twisted pairs for digital input signal lines, with clear identification on the terminal blocks to avoid incorrect wiring.

- For pulse or counting signals, configure appropriate pull-up/pull-down resistors on the hardware to ensure signal quality.

Debugging

- Use the engineering software provided by HIMA for module identification, channel mapping, and parameter configuration.

- Verify the status of each input channel through the software self-test function, and confirm that the fault detection and debouncing functions are normal.

Daily Maintenance

- Regularly check the tightness of the connections of the power supply and communication interface, and remove dust and corrosion.

- Monitor the status indicator lights of the module; when a yellow or red light appears, check the system log in a timely manner to locate the root cause of the fault.

- Perform periodic calibration according to the on-site use environment (such as temperature, humidity) to ensure the accuracy of the input signals.

Replacement and Upgrade

- Adopts a hot-swappable design; faulty modules can be directly replaced after the system is shut down, minimizing downtime.

- If it is necessary to expand the number of channels, sub-modules of the same model can be added to the same rack, and the system will automatically identify and update the configuration.

————————————————————————————————————-

If you would like to learn more about our products and services, please feel free to contact us at any time!

- Sales Manager : Jinny

- Email : sales5@xrjdcs.com

- Whatsapp/Mobile:+86 15359273791

Global renowned brand cooperation

ABB 丨 GE 丨Allen Bradley 丨 Honeywell 丨 Emerson 丨 Bently Nevada 丨 Westinghouse

Triconex 丨 Foxboro 丨 ICS Triplex 丨 Hima 丨 Schneider 丨 Yokogawa 丨 Woodward

—————————————————————————————

Our DCS Spare Parts: What Makes Us Different

1. Deep Expertise

2. Tailored Products

3. Proactive Service

4. Transparent Low Prices

5. Trusted Reputation

Why Choose Us?

- Hassle-Free: We handle everything from part checks to after-sales.

- Genuine Parts: Traceable certificates eliminate counterfeits.

- Long-Term Savings: Proactive support and quality parts reduce maintenance costs.