Welcome to our websites!

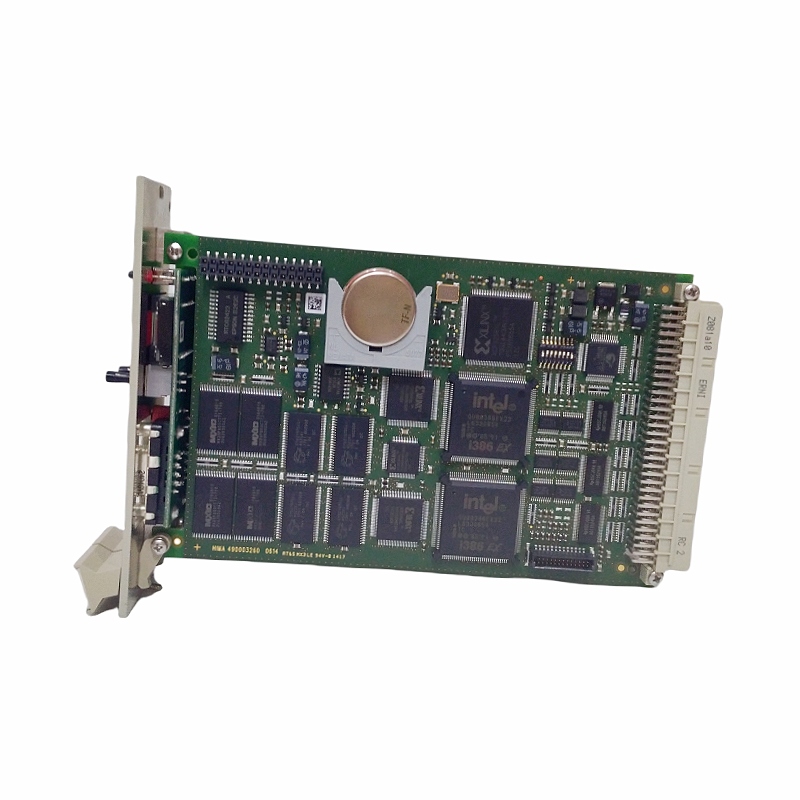

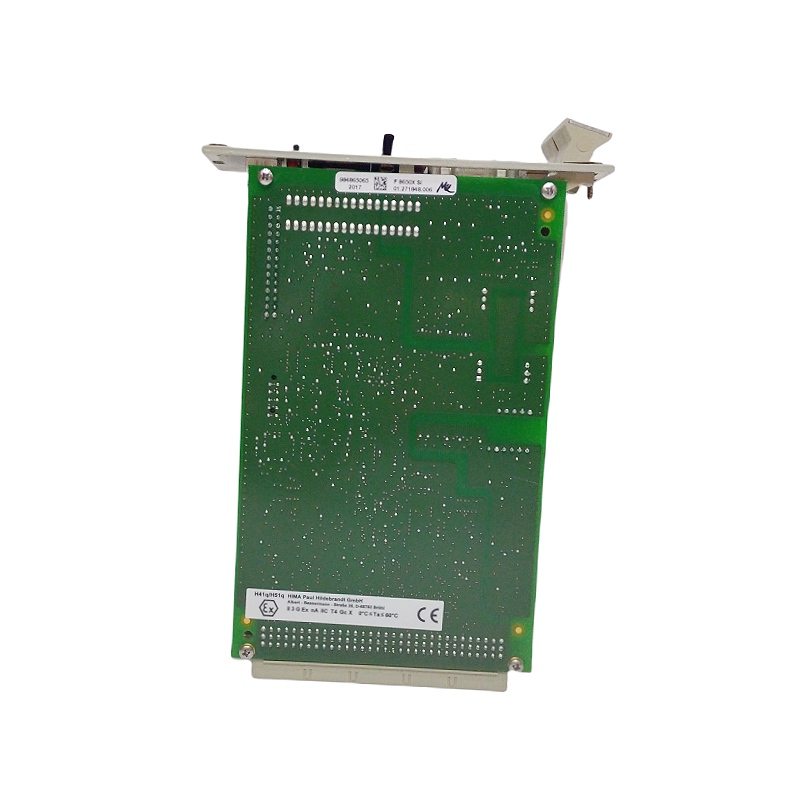

HIMA F8650X CPU module

HIMA F8650X

HIMA F8650X is a core CPU module designed by HIMA for Safety Instrumented Systems (SIS), and it belongs to HIMA’s third-generation PES (Process-Safety-System) platform. The module adopts a dual-microprocessor redundant architecture, complies with international safety standards such as IEC 61508 and IEC 62061, and has obtained SIL 3 / Cat. 4 certification. It is suitable for industrial sites with extremely high requirements for reliability and safety.

Main Technical Parameters

- Power Supply: 24 V DC (input voltage range: 0 ~ 55 V DC)

- Processor: Dual Intel 386EX 32-bit microprocessors with a clock speed of 25 MHz (some documents indicate it is based on ARM Cortex-A9 with a maximum clock speed of 1.2 GHz)

- Memory: For each processor: 1 MB Flash-EPROM (for operating system) + 1 MB Flash-EPROM (for user programs) + 1 MB SRAM (for data)

- I/O Channels: 8 digital inputs, 8 digital outputs (can also be configured as analog I/O)

- Communication Protocols: Modbus, PROFIBUS, Ethernet/IP, Safety-Ethernet (supports Ethernet-based safety communication)

- Operating Temperature: -40 °C ~ +85 °C (some documents mark it as -40 °C ~ +70 °C)

- Installation Method: DIN-Rail mounting, with dimensions of approximately 150 mm × 100 mm × 50 mm

- Other Features: High-availability design, redundant power supply, remote diagnosis and monitoring, support for online modification and expansion

Product Features

- Dual Redundant Microprocessors: Two synchronously operating CPUs provide fault tolerance, ensuring the system can still run safely in case of a single-point failure.

- Compliance with SIL 3 / Cat. 4: Certified to IEC 61508 and IEC 62061, meeting the strictest safety integrity requirements.

- Flexible I/O Configuration: Supports hot-swapping of digital, analog, and fieldbus modules, facilitating rapid expansion according to on-site needs.

- Multi-Protocol Compatibility: Built-in industrial communication protocols such as Modbus, PROFIBUS, and Ethernet/IP, enabling seamless integration into existing control networks.

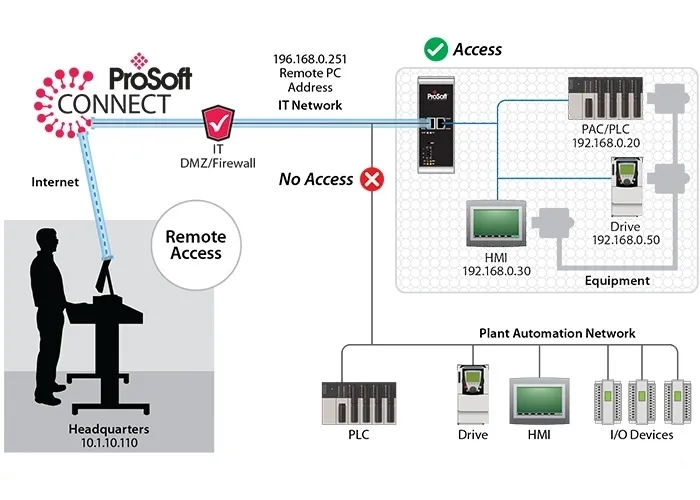

- Remote Monitoring and Diagnosis: Provides user-friendly configuration tools and remote diagnosis functions to reduce on-site maintenance costs.

- High Reliability: Wide operating temperature range, resistance to vibration and electromagnetic interference, suitable for harsh industrial environments.

Structure and Composition

- CPU Core Board: Dual Intel 386EX (or ARM Cortex-A9) microprocessors, and clock synchronization circuit.

- Storage Sub-board: Flash-EPROM and SRAM, used for system firmware, user programs, and operating data respectively.

- Power Supply Module: Internal redundant power management, supporting 24 V DC input and providing regulated output.

- Communication Interface Board: Provides multiple fieldbus ports such as Ethernet, PROFIBUS, and Modbus.

- I/O Expansion Slots: Used for inserting digital, analog, or dedicated function modules (e.g., safety relays, valve drives).

- Enclosure and Installation Accessories: DIN-Rail mounting structure, equipped with protective covers and heat sinks.

Typical Application Fields

- Safety Instrumented Systems (SIS) in the chemical, petroleum, and natural gas industries

- Process safety control in power plants and nuclear power stations

- Safety monitoring for continuous production processes such as papermaking, food, and beverages

- Explosion-proof and leak-proof systems for critical facilities

- Any industrial automation project requiring SIL 3 level safety integrity

Key Points for Installation and Maintenance

- Pre-Installation Inspection: Confirm that the DIN-Rail installation position is firm and the power supply voltage complies with the 24 V DC range.

- Wiring Specifications: Correctly wire the input/output channels and communication ports according to the module manual, ensuring good signal line shielding and grounding.

- Software Configuration: Use the configuration tool provided by HIMA to set CPU parameters, redundancy settings, and I/O mapping, and perform offline simulation verification after completion.

- Function Testing: After power-on, perform self-test to check whether the redundant CPU synchronization status, communication connectivity, and safety functions (e.g., fault switching) are normal.

- Regular Maintenance: Conduct on-site inspections every 6 ~ 12 months, focusing on checking whether there is dust accumulation on power terminals and heat sinks, and whether interface connections are loose.

- Remote Diagnosis: Use the module’s remote monitoring function to download log files regularly and analyze potential abnormalities or performance degradation trends.

- Replacement and Upgrade: When replacing the module, keep the same hardware version number to avoid compatibility issues; if firmware upgrade is required, be sure to complete it during the shutdown window and make a rollback backup.

————————————————————————————————————-

If you would like to learn more about our products and services, please feel free to contact us at any time!

- Sales Manager : Jinny

- Email : sales5@xrjdcs.com

- Whatsapp/Mobile:+86 15359273791

Global renowned brand cooperation

ABB 丨 GE 丨Allen Bradley 丨 Honeywell 丨 Emerson 丨 Bently Nevada 丨 Westinghouse

Triconex 丨 Foxboro 丨 ICS Triplex 丨 Hima 丨 Schneider 丨 Yokogawa 丨 Woodward

—————————————————————————————

Our DCS Spare Parts: What Makes Us Different

As a specialized DCS spare parts supplier, we deliver unique value beyond standard sales—here’s how:

1. Deep Expertise

We specialize in DCS parts, with in-depth knowledge of ABB, FOXBORO, TOSHIBA, ALSTOM, HITACHI. Our technical support not only fixes failures but also prevents them, cutting downtime.

2. Tailored Products

We cover both mainstream and hard-to-find DCS models (from top brands) to match your unique setup—no need to switch vendors.

3. Proactive Service

We respond fast, clarify your needs, and share real-time shipment updates. It’s more than “prompt”—it’s predictive.

4. Transparent Low Prices

Direct partnerships with manufacturers let us skip middlemen. We pass savings to you, with no hidden fees and no quality cuts.

5. Trusted Reputation

Built on long-term client partnerships (power, manufacturing, etc.), we prioritize your success: free wrong-part exchanges and compensation for delayed deliveries. 80% of buyers return.

Why Choose Us?

- Hassle-Free: We handle everything from part checks to after-sales.

- Genuine Parts: Traceable certificates eliminate counterfeits.

- Long-Term Savings: Proactive support and quality parts reduce maintenance costs.

Write your message here and send it to us