Welcome to our websites!

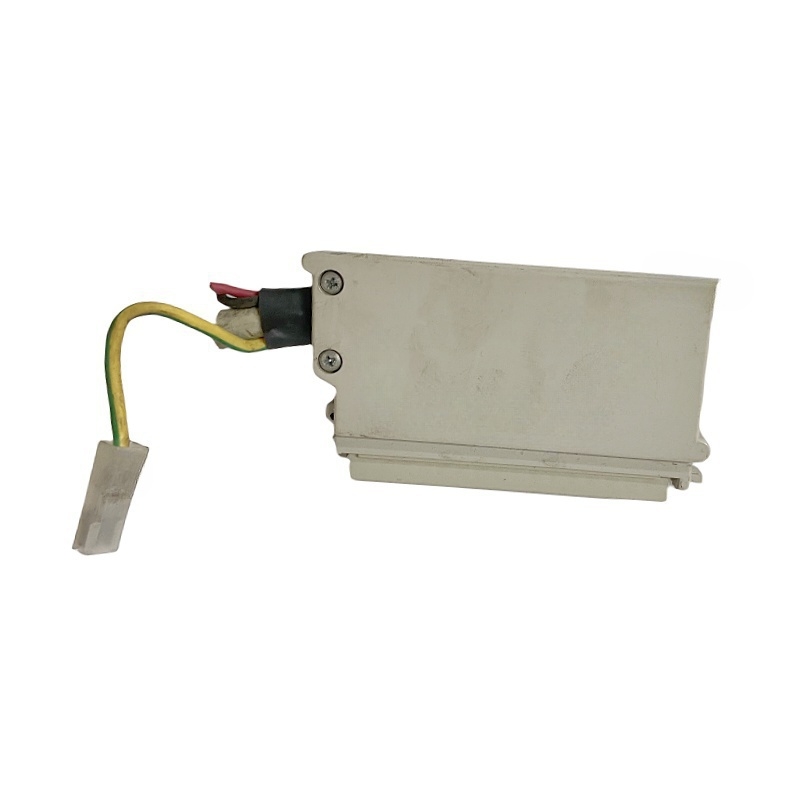

HIMA Z7126 Input Module

HIMA Z7126

Overview

The HIMA Z7126 is a high-performance, high-density analog input module specifically designed by HIMA for its mature HIMax® safety control system. In the Safety Instrumented System (SIS), this module serves as a crucial “precision collector” for process signals. Its primary function is to simultaneously receive multiple 4-20mA analog signals from on-site transmitters and convert them into digital data with high precision, which is then used by the system’s main processor for logical operations and hazard assessment. As a key component of the HIMax series I/O modules, the HIMA Z7126 module is renowned for its excellent channel density and measurement accuracy. It incorporates advanced signal conditioning and isolation technologies internally, ensuring that each signal is processed independently and that sufficient electrical isolation is achieved between signals and between the signal side and the system side. This effectively prevents ground loops and electromagnetic interference, guaranteeing the accuracy and stability of signal measurement. This is vital for monitoring critical process variables such as pressure, temperature, flow rate, and liquid level, and serves as a reliable underlying guarantee for realizing SIL 3-level safety functions like Emergency Shutdown (ESD) and Fire and Gas Detection (F&G).

Product Parameters

- Product Model: Z7126

- Manufacturer: HIMA

- Product Type: Analog Input Module (4-20mA)

- Number of Channels: 16 channels (high density)

- Input Signal Type: 4-20mA (configurable for active/passive)

- Resolution: 15 bits (binary)

- Accuracy: ±0.1% of reading (typical value)

- Maximum Load: 750 Ω (per channel)

- Isolation: Isolation between channels, 500 V AC

- Common Mode Rejection Ratio: >120 dB @ 50/60 Hz

- Supply Voltage: 5 VDC (provided by the HIMax rack backplane)

- Operating Temperature: 0°C to +60°C

- Safety Certification: SIL 3 (in accordance with IEC 61508)

Structure and Composition

The HIMA Z7126 module adopts the standard modular design of the HIMax series. Its robust metal housing ensures excellent Electromagnetic Compatibility (EMC) and mechanical strength. A row of status indicator lights is installed on the front of the module to display the module’s power status and communication activity. At the core of its internal structure are multiple high-precision signal processing chains. Each channel includes a dedicated signal conditioning circuit, filter, and 16-bit Analog-to-Digital Converter (ADC), ensuring that each input signal is independently and accurately digitized. The module uses high-performance isolation devices (such as optocouplers or magnetic couplers) internally to achieve electrical isolation between channels, as well as between the on-site side and the system logic side. This is key to ensuring the system operates stably in high-noise industrial environments and meets safety level requirements. The module is connected to the backplane bus of the HIMax rack via a multi-pin connector at the rear, obtaining operating power from the backplane and transmitting the converted digital data to the main processor.

Application Fields

The HIMA Z7126 high-density analog input module is widely used in process industry safety systems that require monitoring of a large number of process variables. In the oil and gas industry, it is deployed in Emergency Shutdown Systems (ESD) of refineries, chemical plants, and offshore platforms to intensively collect key parameters such as reactor pressure, fractionating tower liquid level, and compressor flow rate. In the chemical industry, it forms the basis of process alarm and interlock systems, monitoring the temperature and pressure of various tanks, kettles, and towers. In the thermal power and nuclear power fields, the Z7126 is used in safety shutdown systems to monitor numerous analog signals such as boiler pressure, steam temperature, and water level. Additionally, in the SCADA (Supervisory Control and Data Acquisition) systems of large oil and gas transmission pipelines, it is also used in data acquisition units at various stations to ensure the reliable acquisition of pipeline operation parameters.

Installation and Maintenance

Preparation Before Installation

Before installing the HIMA Z7126 module, it is essential to ensure that the power supply of the HIMax system rack is completely turned off. Check that the rack slot is free and that the backplane connector is in good condition. Prepare the on-site signal wiring required for the module and ensure that all wiring complies with explosion-proof and anti-interference specifications. Operators should wear anti-static wristbands to prevent damage to electrostatically sensitive components.

Maintenance Recommendations

During system operation, the status of the Z7126 can be monitored in real-time through the indicator lights on the front of the module and the system diagnostic software. Regularly use software functions to check the calibration and health status of the channels. When a channel reports a fault, first check the on-site wiring and transmitter. If module replacement is necessary, ensure that the system is powered off or that the slot has been disabled by software. Then, loosen the module fixing screws and smoothly pull the module out of the backplane. When inserting a new module, align it with the guide rails and push it in with even force. After confirming that the connector is fully in place, tighten the screws. Finally, power on the system and verify that the module status is normal in the software.

————————————————————————————————————-

If you would like to learn more about our products and services, please feel free to contact us at any time!

- Sales Manager : Jinny

- Email : sales5@xrjdcs.com

- Whatsapp/Mobile:+86 15359273791

Global renowned brand cooperation

ABB 丨 GE 丨Allen Bradley 丨 Honeywell 丨 Emerson 丨 Bently Nevada 丨 Westinghouse

Triconex 丨 Foxboro 丨 ICS Triplex 丨 Hima 丨 Schneider 丨 Yokogawa 丨 Woodward

—————————————————————————————

Our Advantages & Services

- Reduce Maintenance Costs: We help you lower equipment maintenance costs by providing high-quality spare parts and professional services.

- Shorten Downtime: With fast spare parts supply, we minimize equipment downtime and enhance production efficiency.

- Extend Equipment Lifespan: Using original or compatible high-quality spare parts helps prolong the service life of your equipment.

- One-Stop Global Supply of PLC Spare Parts: No matter which brand or model of PLC spare parts you need, we can provide you with fast and accurate solutions.

- Professional Team & Technical Support: We have a team of experienced engineers to offer you professional technical support and maintenance services.

- Original Factory Quality at Preferential Prices: The PLC spare parts we provide are either original or compatible products, ensuring quality while offering more competitive prices.

- Rapid Response & Global Shipping: Equipped with a sound logistics system, we can quickly respond to your needs and deliver spare parts to you in a timely manner.

Company’s Advantageous Services

- We have long been engaged in the industrial control industry and maintain a large inventory.

- Leading in the industry, with price advantages and quality assurance.

- A wide range of models and products, including various rare and discontinued products.

- Free replacement is available within 15 days if there are quality issues.

Our product range covers various modules, cards, drivers, controllers, servo motors, embedded cards, wires & cables, power modules, and control modules. These products are suitable for industries such as iron and steel, hydropower, nuclear power, power generation, glass manufacturing, tire factories, rubber production, thermal power generation, papermaking, shipping, and navigation.

Write your message here and send it to us