GE SR469-P5-H-A20-T Relay

GE SR469-P5-H-A20-T

I. Overview

The GE SR469-P5-HI-A20 is a high-performance and highly reliable motor management relay, specifically designed for medium and high-voltage motors, offering comprehensive protection and control functions. It adopts advanced microprocessor technology and is equipped with high-precision current, voltage, and temperature monitoring capabilities. It can effectively prevent motor faults such as overload, short circuit, ground fault, voltage loss, and undervoltage, ensuring the safe operation of motors in various industrial environments.

II. Parameters

Rated voltage: 90-300 VDC or 70-265 VAC (some models support 12-48 VDC input voltage).

Rated current: 5 A (phase CT secondary coil).

Analog output: 4 channels of 4-20 mA analog output.

Operating temperature range: -40°C to +85°C (some models can reach -20°C to +60°C).

Storage temperature range: -40°C to +80°C (some models can reach -65°C to +150°C).

Protection class: IP20 or IP54 (some models are IP67).

Dimensions: 230 mm x 165 mm x 80 mm (some models are 21.8×22.8×25 cm).

Weight: approximately 2.2 kg (some models are 7.32 kg).

Communication interfaces: supports protocols such as RS232, RS485, Modbus RTU, Modbus TCP/IP, Ethernet, etc.

III. Product Features

Comprehensive protection functions: provides various protection functions such as overload, short circuit, ground fault, voltage loss, undervoltage, phase loss, single-phase operation, locked rotor, etc.

High reliability: adopts advanced microprocessor technology and redundant design to ensure the stability and reliability of the system.

Compact design: easy to install and maintain, suitable for various industrial environments.

LCD display: the front panel is equipped with a large LCD display that can show 40 characters, facilitating information reading and diagnosis.

Programmability: supports user-defined control logic and parameter settings to meet different application requirements.

Data collection and processing: can acquire and process data such as motor current, voltage, and power factor, facilitating remote monitoring and maintenance.

Easy to install and use: compact size and intuitive operation interface allow users to get started quickly.

IV. Structure and Composition

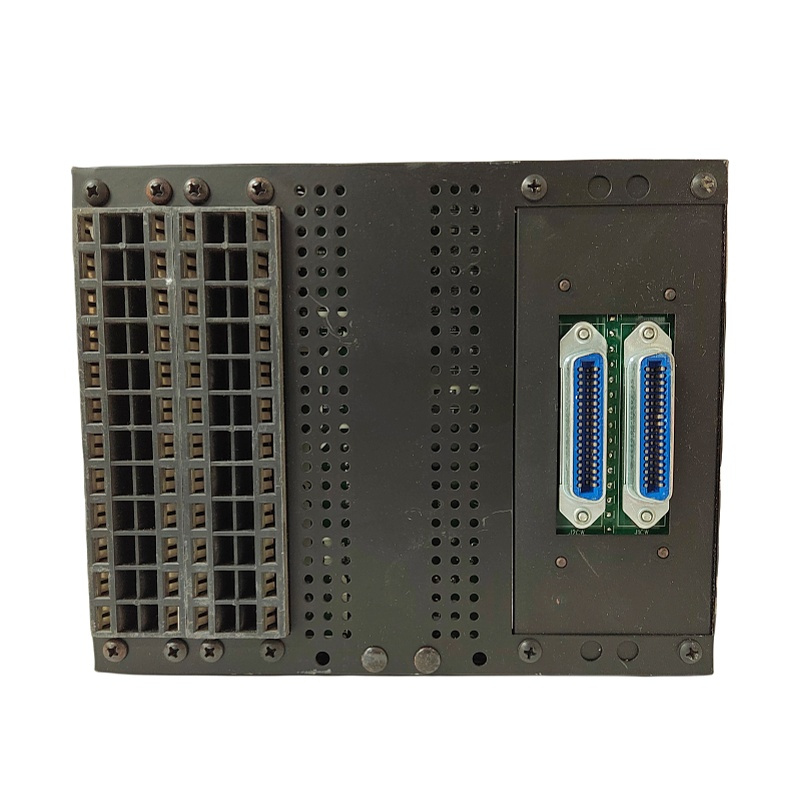

The GE SR469-P5-HI-A20 consists of multiple modules, including:

Main unit: responsible for the protection and control functions of the motor.

Current transformer secondary input module: used to collect the current signal of the motor.

Analog output module: provides 4 channels of 4-20 mA analog output for control and monitoring.

Communication module: supports multiple communication protocols, facilitating integration with automation systems.

Front panel: equipped with RS-232 program port interface, sealed pull-out handle, LCD display, etc.

V. Application Fields

The GE SR469-P5-HI-A20 is widely used in the following fields:

Power industry: motor protection in power plants and substations.

Metallurgical industry: motor control of equipment such as rolling mills and cranes.

Petroleum and chemical industry: motor protection of equipment such as pumps and fans.

Construction industry: motor control of equipment such as air conditioners and elevators.

Industrial automation: applications requiring motor control in various production processes.

Transportation: elevators, escalators, subway systems, etc.

Water treatment and wastewater treatment: motor protection of pumps and other equipment.

VI. Installation and Maintenance

Installation methods:

DIN rail mounting: applicable to most models, easy to install and maintain.

Panel mounting: some models support panel mounting, suitable for environments with limited space.

Sealed design: the front panel has a sealing function to prevent unauthorized removal.

Installation steps:

Ensure that the installation environment meets the operating temperature and humidity requirements of the product.

Install according to the product manual to ensure correct wiring.

Use appropriate tools for installation to avoid damaging the equipment.

Maintenance suggestions:

Regularly check the connection and operating status of the equipment.

Clean the surface of the equipment to prevent dust and dirt from affecting performance.

Regularly update the firmware and software to ensure the latest functions and security of the equipment.

————————————————————————————————————-

If you would like to learn more about our products and services, please feel free to contact us at any time!

- Sales Manager : Jinny

- Email : sales5@xrjdcs.com

- Whatsapp/Mobile:+86 15359273791

Global renowned brand cooperation

ABB 丨 GE 丨Allen Bradley 丨 Honeywell 丨 Emerson 丨 Bently Nevada 丨 Westinghouse

Triconex 丨 Foxboro 丨 ICS Triplex 丨 Hima 丨 Schneider 丨 Yokogawa 丨 Woodward

—————————————————————————————

Our product range is extensive, covering all aspects of automation systems, mainly including:

- PLC Controllers: PLC controllers and peripheral equipment from brands such as ABB, Siemens, and Omron.

- DCS Systems: Spare parts for DCS systems from brands like ABB, FOXBORO, and Honeywell.

- Inverters: Inverters from brands including ABB, Siemens, and Yaskawa.

- Servo Motors: Servo motors from brands such as Yaskawa and Panasonic.

- Sensors: Sensors from brands like ABB and Honeywell.

- I/O Modules: I/O modules from brands including ABB.

Our customers are spread across various industries, including:

- Petrochemical

- Electric power

- Iron and steel

- Pharmaceutical

- Food and beverage

- Water treatment