Welcome to our websites!

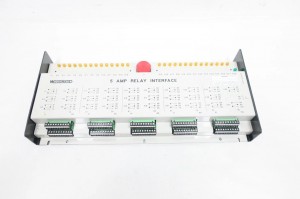

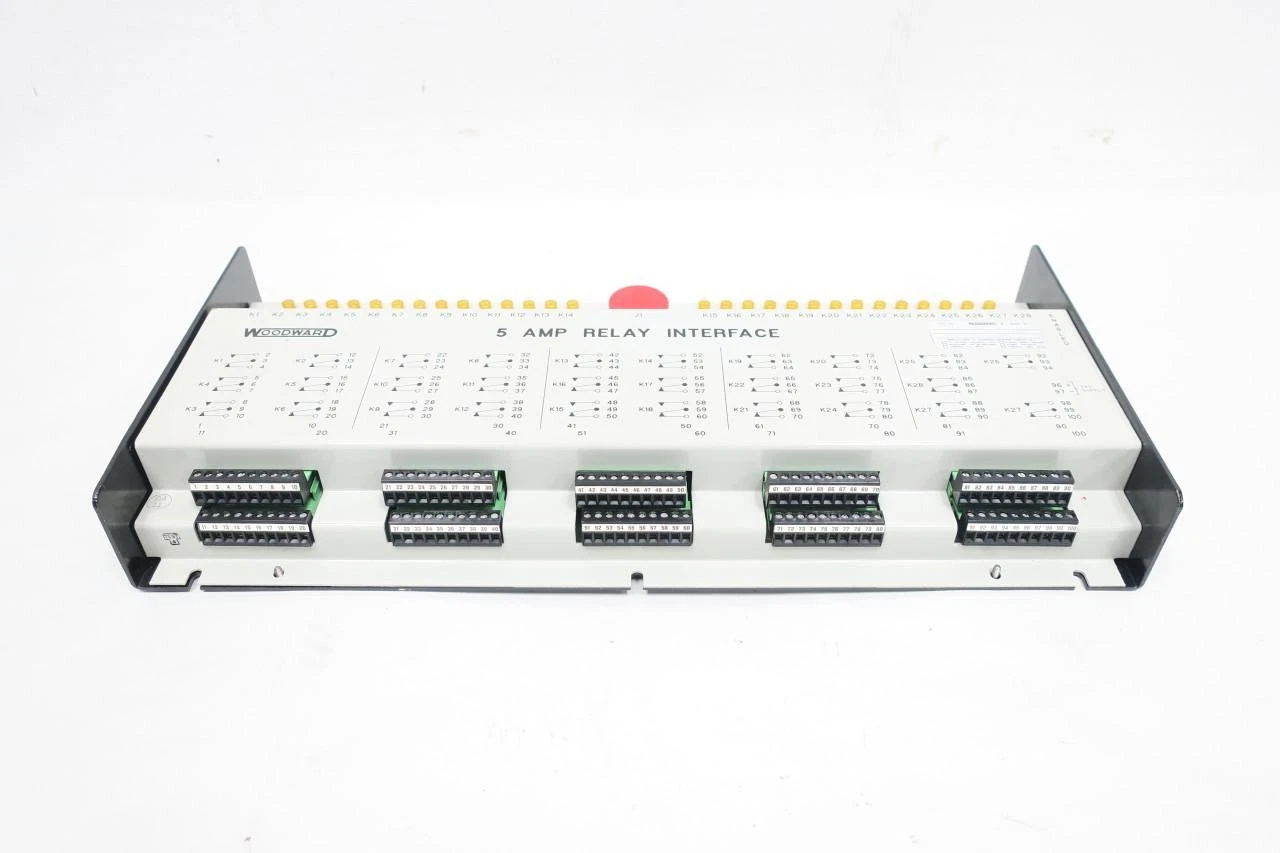

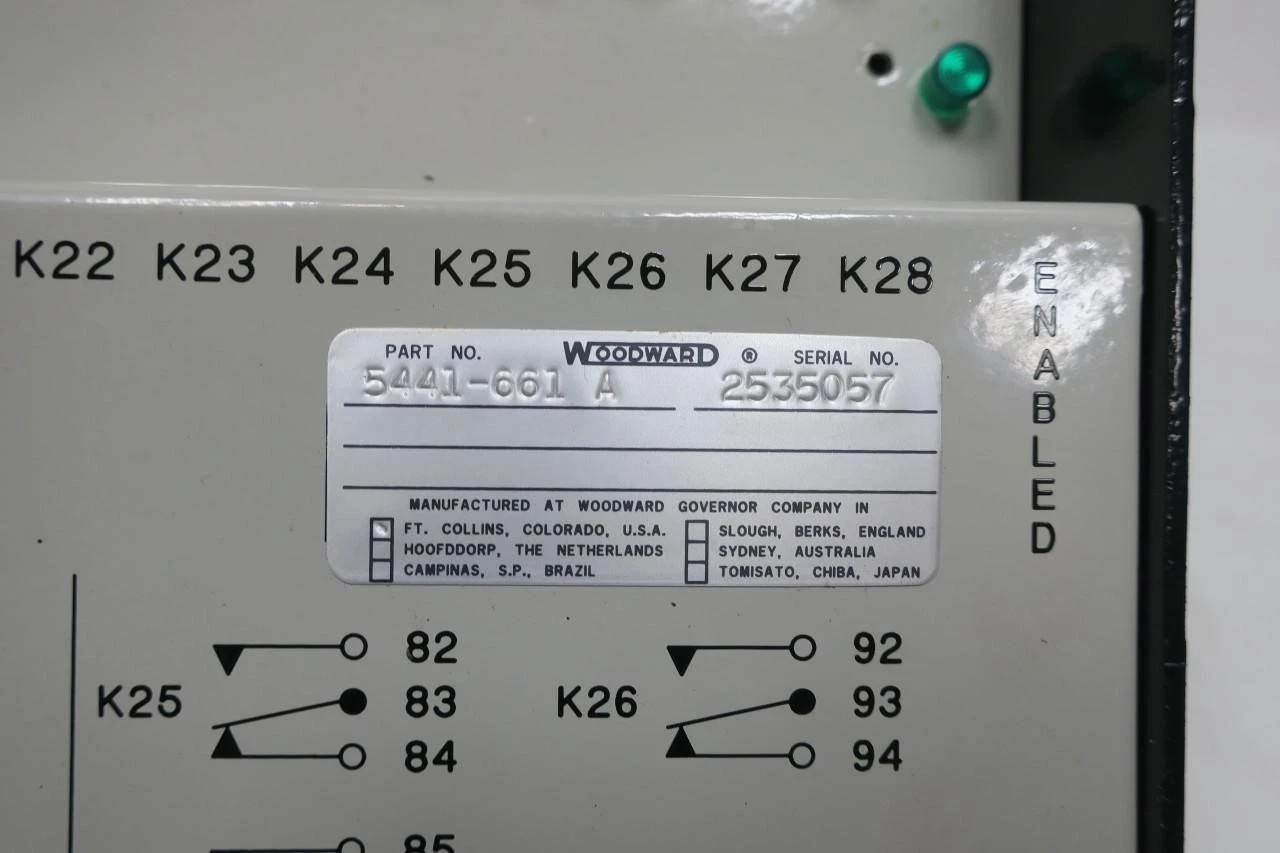

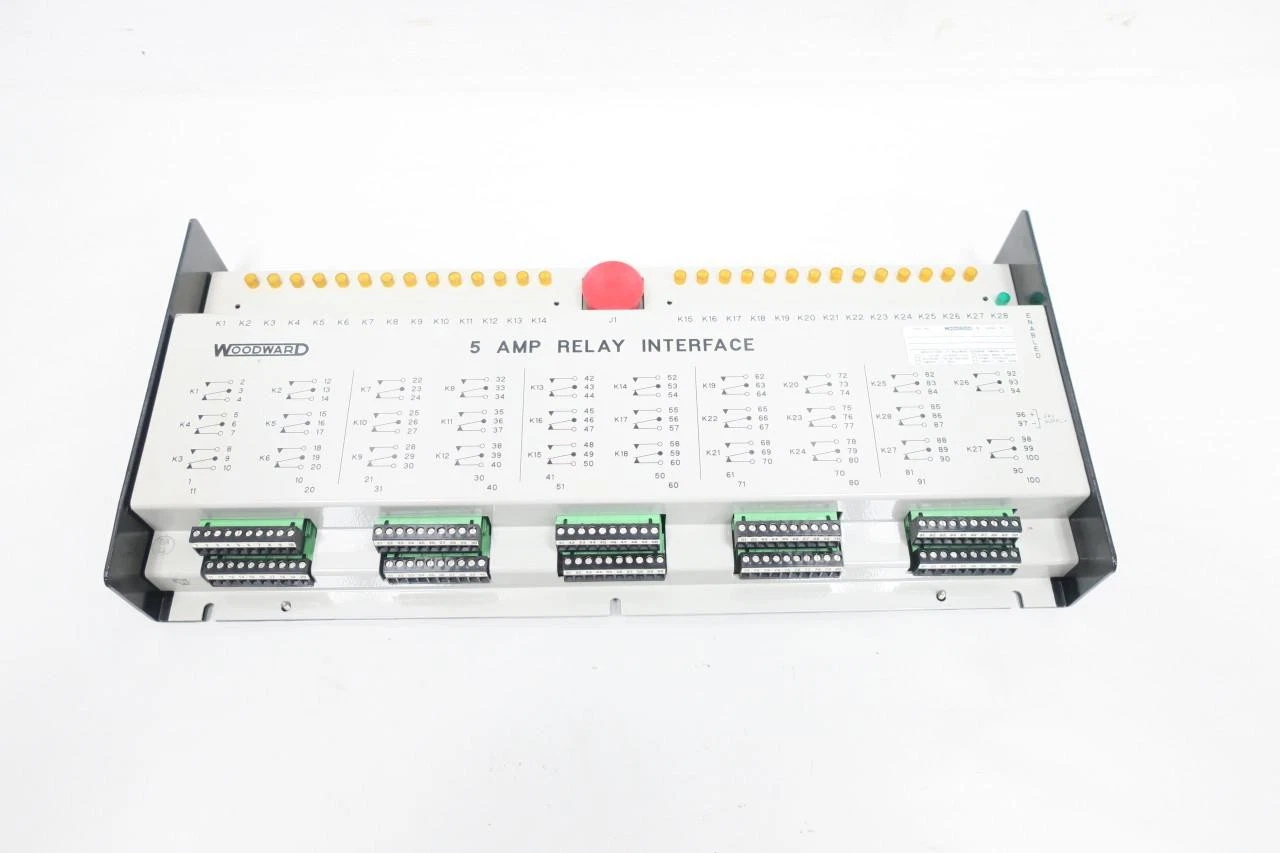

Woodward 5441-661 Relay Interface Module

Woodward 5441-661

Product Positioning

Woodward 5441-661 is a relay interface module under the Woodward Speed Control series. It is mainly used for closed-loop speed regulation of rotational machinery such as engines, gas turbines, and generator sets, controlling parameters like speed, power, or fuel flow.

Core Functions

- Provides 1 A (5 A/10 A optional) relay output, compatible with 24 VDC/120 VAC control signals.

- Supports multi-channel I/O combinations, enabling direct digital/analog signal interaction with Woodward main controllers (e.g., 5501-467, 5466-316) or on-site PLCs.

Key Technical Parameters

| Parameter | Specification |

|---|---|

| Input Voltage | 24 VDC |

| Output Current | 5 A (standard) / 10 A (high-power version) |

| Output Channel | Single relay interface |

| Operating Temperature | –40 ℃ ~ +85 ℃ |

| Protection Class | IP65 (dustproof and waterproof) |

| Dimensions | Approximately 70 mm × 35 mm × 25 mm (compact type) |

| Weight | Approximately 60 g |

| Communication Interface | RS-485 (Modbus/TCP) or fieldbus |

| Power Supply Method | Direct connection to 24 VDC power supply of the main control cabinet |

Structure and Composition

- Housing: Made of metal or high-strength plastic, complying with IP65 protection standards.

- Relay Unit: Adopts electromagnetic relays with silver alloy contact materials to ensure high reliability and low contact resistance.

- Power Module: Equipped with an internal voltage stabilization circuit, converting external 24 VDC to the voltage required by the relay coil.

- Signal Interface: Comes with terminal blocks or DIN-rail interfaces for easy on-site wiring.

- Communication Board: RS-485/Modbus interface board, supporting remote monitoring and parameter downloading.

- Heat Sink: Provides passive heat dissipation during high-power operation to ensure long-term stable performance.

Typical Application Fields

- Gas Turbine/Steam Turbine Speed Regulation: Cooperates with Woodward main control systems to achieve precise closed-loop control of speed and fuel flow.

- Generator Sets: Used for generator speed protection, load distribution, and automatic start-stop.

- Marine Engines: Provides reliable speed control in marine and offshore operations.

- Industrial Automation: Works with PLCs to realize speed/power linkage control of large machinery.

- Renewable Energy Systems: Power regulation and protection for wind power and photovoltaic inverters.

Installation Points

- Fixing Method: Adopt DIN-rail installation, ensuring the module is placed horizontally for easy later maintenance.

- Power Wiring: Use cables conforming to IEC 60320 standards, ensuring correct power polarity to avoid reverse connection.

- Signal Wiring: Use shielded wires or twisted pairs for relay output terminals to prevent electromagnetic interference.

- Grounding: The housing must be reliably grounded to meet safety specifications.

- Heat Dissipation: Install in a well-ventilated cabinet, and add auxiliary heat sinks if necessary.

Maintenance and Troubleshooting

Maintenance Items

| Maintenance Item | Recommended Cycle | Key Check Points |

|---|---|---|

| Visual Inspection | Monthly | Integrity of the housing, tightness of wiring, and dust accumulation on the heat sink |

| Electrical Testing | Every 6 months | Relay coil resistance, contact resistance, and whether the power supply voltage is within the rated range |

| Communication Verification | Quarterly | RS-485 signal integrity, Modbus address conflicts, and parameter backup |

| Function Verification | Annually | Conduct a complete closed-loop speed regulation test through the main controller to confirm response time and threshold settings |

Common Faults and Solutions

- Relay Failure to Operate: Check the coil voltage and whether the relay contacts are stuck; replace the relay unit if necessary.

- Communication Failure: Confirm the RS-485 terminal resistance, check for damage to the bus cable, and reconfigure communication parameters.

- Overheating Alarm: Check if the heat sink is blocked, confirm whether the ambient temperature exceeds the rated upper limit, and add a fan if necessary.

————————————————————————————————————-

If you would like to learn more about our products and services, please feel free to contact us at any time!

- Sales Manager : Jinny

- Email : sales5@xrjdcs.com

- Whatsapp/Mobile:+86 15359273791

Global renowned brand cooperation

ABB 丨 GE 丨Allen Bradley 丨 Honeywell 丨 Emerson 丨 Bently Nevada 丨 Westinghouse

Triconex 丨 Foxboro 丨 ICS Triplex 丨 Hima 丨 Schneider 丨 Yokogawa 丨 Woodward

—————————————————————————————

Our Company’s Advantageous Services

- Boasting years of expertise in the industrial control sector, we maintain an extensive stock of related products.

- As a leader in the industry, we deliver competitive pricing alongside reliable product quality guarantees.

- We offer a diverse selection of models and products, covering various rare items as well as discontinued industrial components.

- For any product quality issues arising within 15 days of purchase, we provide free replacement services.

Our product range – which includes modules, cards, drivers, controllers, servo motors, embedded cards, wires, cables, power modules, and control modules – is well-suited for industries such as iron and steel production, hydropower, nuclear power, power generation, glass manufacturing, tire plants, rubber processing, thermal power generation, papermaking, shipping, and navigation.

Core Products

Our main offerings include PLCs, DCS systems, CPU modules, communication modules, input/output modules (AI/AO/DI/DO), power modules, thyristor modules, terminal modules, PXI modules, servo drives, servo motors, industrial displays, industrial keyboards, controllers, encoders, regulators, sensors, I/O boards, counting boards, fiber optic interface boards, acquisition cards, gas turbine cards, FIM cards, and other automation spare parts.

Write your message here and send it to us