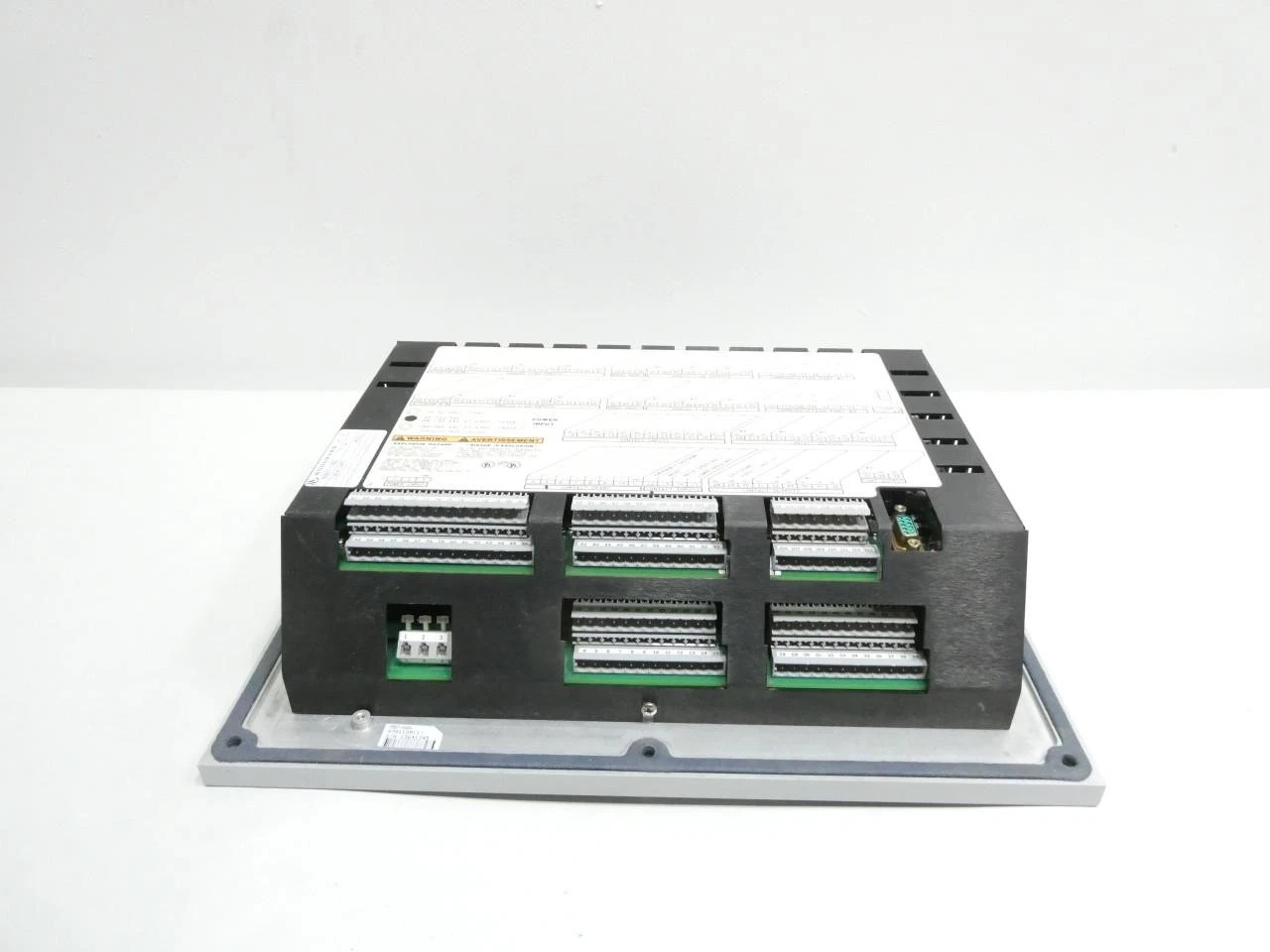

Woodward 9907-166 505 Processor Control Unit

Woodward 9907-166 505

The Woodward 9907-166 is a digital microprocessor control unit belonging to the Woodward 505/505E series. It is specifically designed for steam turbines, including those used in marine propulsion, power stations, and small industrial installations. Equipped with a 32-bit microprocessor, it supports on-site programming and multiple control modes (such as speed, power, and pressure). Additionally, it features a redundant design and self-diagnostic functions to ensure high reliability.

Main Technical Specifications

- Power Supply: AC 88-132 VAC or DC 90-150 VDC

- Operating Temperature: -25 °C to 65 °C (without enclosure); maximum 55 °C when equipped with an NEMA 4X protective enclosure

- Dimensions/Weight: Approximately 14 in × 11 in × 4 in (about 9.1 lb)

- Signal Interface: 4-20 mA, 0-10 V, digital I/O; optional RS-232/RS-485 Modbus communication

- Control Functions: PID, proportional, fuzzy control, load sharing, closed-loop control for speed/power/pressure; supports on-site programming and parameter adjustment

- Protection Rating: IP56 (IEC 60529) or NEMA 4X protective enclosure

- Environmental Adaptability: Suitable for harsh industrial environments, with dust-proof, moisture-proof, and corrosion-resistant properties

Product Features

- High-Performance Control: Offers multi-mode control and various regulation strategies, providing fast and accurate speed and load adjustment.

- Strong Reliability: Features redundant hardware design, fault self-diagnosis, and alarm functions, making it suitable for critical industrial systems.

- Flexible Configuration: Supports a variety of sensors/actuators, and on-site programming allows customization according to user needs.

- Easy Installation and Maintenance: Enables DIN rail or NEMA 4X enclosure installation, with a modular I/O design for convenient wiring, replacement, and on-site debugging.

- Open Architecture: Compatible with multiple industrial networks (Modbus, RS-232/422), facilitating integration with DCS and SCADA systems.

Structure and Composition

- Main Control Board: Includes a 32-bit microprocessor, memory, and communication interfaces.

- Power Supply Module: Provides voltage stabilization and filtering, supporting dual AC/DC power input.

- I/O Module: Consists of analog inputs (current/voltage), digital inputs/outputs, and relay outputs.

- Enclosure: Optional IEC IP56 or NEMA 4X protective enclosure to adapt to different environments.

- Keyboard/Display: A 30-key multi-function keyboard combined with a two-line, 24-character display for on-site operation and parameter checking.

Typical Application Fields

- Power Plant Steam Turbines: Closed-loop control of speed, power, and pressure.

- Marine Propulsion Systems: Speed and load adjustment for marine steam turbines or gas turbines.

- Industrial Steam-Driven Equipment: Steam turbines used in industries such as chemical engineering, petroleum, and papermaking.

- Small Expanders or Micro-Power Generation Devices: Suitable for distributed energy systems or experimental platforms.

Installation Key Points

- Location Selection: Ensure good ventilation and avoid high-temperature, highly corrosive environments; select an NEMA 4X enclosure if protection is required.

- Power Wiring: Connect according to the power supply specifications (AC or DC), using cables that comply with the IEC 60320 standard.

- I/O Wiring: Adopt standard terminal blocks or DIN rail terminals to ensure proper shielding and grounding of signal wires.

- Keyboard/Display Installation: Fix it on the operation panel for easy on-site debugging.

- Communication Interface: Select RS-232, RS-485, or Ethernet modules based on the on-site network, and configure the corresponding protocol (Modbus).

Maintenance Recommendations

- Regular Inspection: Check the power supply, wiring, and terminal tightness every 6-12 months; verify the tight seal of the protective enclosure.

- Firmware Upgrade: Use the 505View/OpView software officially provided by Woodward to update the firmware, maintaining the latest functions and security patches.

- Self-Diagnostic Logs: Utilize the built-in fault self-diagnostic function to export logs regularly and analyze potential abnormalities.

- Spare Parts Management: Keep critical components such as power supply modules, I/O cards, and keyboards/displays in stock to minimize maintenance downtime.

————————————————————————————————————-

If you would like to learn more about our products and services, please feel free to contact us at any time!

- Sales Manager : Jinny

- Email : sales5@xrjdcs.com

- Whatsapp/Mobile:+86 15359273791

Global renowned brand cooperation

ABB 丨 GE 丨Allen Bradley 丨 Honeywell 丨 Emerson 丨 Bently Nevada 丨 Westinghouse

Triconex 丨 Foxboro 丨 ICS Triplex 丨 Hima 丨 Schneider 丨 Yokogawa 丨 Woodward

—————————————————————————————

Our Company’s Advantageous Services

- Boasting years of expertise in the industrial control sector, we maintain an extensive stock of related products.

- As a leader in the industry, we deliver competitive pricing alongside reliable product quality guarantees.

- We offer a diverse selection of models and products, covering various rare items as well as discontinued industrial components.

- For any product quality issues arising within 15 days of purchase, we provide free replacement services.

Core Products