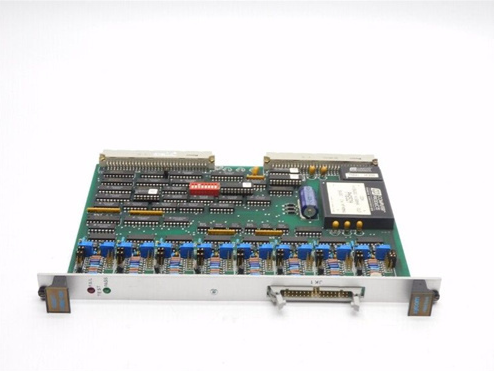

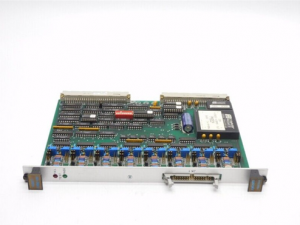

XYCOM 3410T Embedded Control Module

XYCOM 3410T

The XYCOM 3410T is an industrial operator interface/embedded controller belonging to the XYCOM Automation 3400 series. It is mainly used for on-site monitoring, process control, and human-machine interaction. It can be used independently as a local HMI or work with upper-level systems such as PLC and DCS to realize functions including data acquisition, parameter setting, and fault diagnosis.

1. Main Technical Specifications

| Parameter | Specification |

|---|---|

| Display Screen | 14-inch TFT LCD, resolution 1024 × 768, resistive touch |

| Processor | Intel Core i5, with a main frequency of 1.7 GHz |

| Memory/Storage | 4 GB DDR3, 64 GB SSD |

| Operating System | Windows 10 IoT Enterprise |

| Communication Interface | 2 × Gigabit Ethernet, 4 × USB 2.0, 1 × USB 3.0, 2 × RS-232, 1 × RS-485 |

| Operating Temperature | –10 ℃ ~ +50 ℃ |

| Protection Level | IP65 |

| Dimension/Weight | 365 × 295 × 60 mm, approximately 5.5 kg |

| Installation Method | Panel-mounted (can be directly mounted on the front panel of equipment) |

2. Product Features

- High Reliability: With IP65 protection and an industrial-grade temperature range, it can adapt to harsh on-site environments.

- Strong Expandability: Equipped with multiple Ethernet, USB, and serial interfaces, it facilitates rapid integration with on-site equipment and upper-level systems.

- User-friendly Interaction: The 14-inch large screen combined with resistive touch ensures clear display and smooth operation.

- Localized Control: Built-in Windows 10 IoT allows it to run local control programs, reducing reliance on upper-level computers.

- Diagnosis and Maintenance: It provides fault logs and real-time diagnostic information to help on-site maintenance personnel quickly locate problems.

3. Structure and Composition

- Display Module: Consists of a 14-inch TFT LCD and a touch layer.

- Main Control Board: A computing platform composed of an Intel Core i5 processor, memory, and SSD.

- Communication Module: Includes Ethernet, USB, and RS-232/RS-485 interface cards.

- Power Supply and Heat Dissipation System: Comprises an industrial-grade power module and cooling fans (or passive heat sinks).

- Shell: Made of metal or high-strength plastic, complying with the IP65 protection standard.

- Installation Bracket: A panel-mounted fixed bracket that is compatible with standard cabinets or on-site panels.

4. Typical Application Fields

| Industry | Application Scenario |

|---|---|

| Production Line Monitoring | Displays machine status and alarm information in real time, allowing operators to adjust parameters on-site. |

| Process Control | Links with PLC/DCS to provide local HMI functions and realize closed-loop control. |

| Equipment Maintenance | Shows diagnostic logs and operation curves to help maintenance personnel quickly locate faults. |

| Embedded Control | With a small size and rich interfaces, it can be directly embedded into equipment with limited space. |

| Energy, Chemical, and Manufacturing Industries | Suitable for on-site control systems that require high reliability and human-machine interaction. |

5. Installation and Maintenance Points

Pre-installation Inspection

- Confirm that the installation location is flat and the fixing screw holes are aligned.

- Check whether the power voltage and grounding meet the specifications.

Fixing Method

- Use the panel brackets provided with the product or standard 3-hole/4-hole mounting holes for screw fixing.

- Ensure the sealed surface of the shell faces outward to meet the IP65 protection requirement.

Wiring

- Connect interfaces such as power supply, Ethernet, USB, and serial ports according to the wiring diagram.

- For RS-232/RS-485, pay attention to the signal polarity and the configuration of terminal resistors.

Debugging

- After power-on, enter the system self-test to confirm that functions such as display, touch, and network are normal.

- Use the built-in diagnostic tool to check the hardware status, temperature, and power supply condition.

Daily Maintenance

- Regularly inspect the sealing rubber strip of the shell to prevent dust and water mist from entering.

- Use a soft, fiber-free cloth to clean the display screen; avoid using strong acid or alkali cleaning agents.

- Check the dust accumulation on internal cooling fans or heat sinks every six months and clean them if necessary.

- Regularly export operation records through system logs to evaluate the health status of the equipment.

————————————————————————————————————-

If you would like to learn more about our products and services, please feel free to contact us at any time!

- Sales Manager : Jinny

- Email : sales5@xrjdcs.com

- Whatsapp/Mobile:+86 15359273791

Global renowned brand cooperation

ABB 丨 GE 丨Allen Bradley 丨 Honeywell 丨 Emerson 丨 Bently Nevada 丨 Westinghouse

Triconex 丨 Foxboro 丨 ICS Triplex 丨 Hima 丨 Schneider 丨 Yokogawa 丨 Woodward

—————————————————————————————

Your Reliable Partner for Customized Automation Solutions

Why Partnering with Us Adds Value to Your Business

- Superior Quality Assurance: Every product and solution undergoes strict quality checks to meet industry-leading standards, minimizing operational risks for your business.

- On-Time Delivery Commitment: We prioritize efficient supply chain management to ensure your orders are delivered promptly, avoiding delays in your production or project timelines.

- Extensive Range of Branded Components: We stock and supply a wide selection of parts from well-known, reputable brands, guaranteeing compatibility and durability.

- Expert Team & Advanced Testing Facilities: Our team of seasoned professionals, combined with state-of-the-art testing equipment, ensures every solution is fully validated before deployment.

- Ample Inventory Reserves: We maintain large inventory levels to meet your urgent needs, reducing lead times and keeping your operations running smoothly.

- 100% Genuine New Products: We strictly provide original, brand-new items—no refurbished or counterfeit products—ensuring the highest quality and long-term performance.