Welcome to our websites!

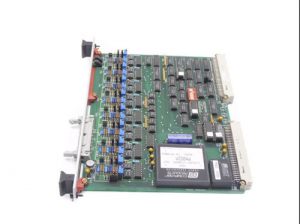

XYCOM 9450-27B2118010 Computer System

XYCOM 9450-27B2118010

1. Product Overview

The XYCOM 9450-27B2118010 is part of the XYCOM 9450 series of industrial PC/AT computer systems. It integrates a PC motherboard, a flat-panel display, a keyboard/button panel, and multiple I/O interfaces into an “all-in-one” operation station.

The system uses industrial-grade components, featuring shock resistance, vibration resistance, and a wide operating temperature range. It can operate reliably in environments ranging from 0 °C to 55 °C, with some models capable of functioning between -20 °C and 70 °C.

2. Main Technical Specifications

| Parameter | Description |

|---|---|

| Processor | Intel Pentium III (or compatible processor with a clock speed of 1 GHz or higher), supporting 32-bit operating systems |

| Memory | DDR SDRAM, with a standard configuration of 256 MB and expandability up to 1 GB |

| Storage | Equipped with a 3.5-inch IDE hard drive bay, supporting capacities of 40 GB or more; SSD is also available as an optional accessory |

| Display | 15.0-inch flat-panel LCD with a resolution of 1024 × 768; the front panel has an NEMA 4/4X/12 protection rating |

| Input Devices | Integrated keyboard/button panel (6–12 keys optional), supporting external USB keyboards/mice |

| I/O Interfaces | 4 × RS-232, 2 × RS-485, 2 × USB 2.0, 1 × VGA, 1 × parallel port, 1 × serial port, 1 × Ethernet (10/100 Mbps) |

| Power Supply | 24 V DC input, power consumption ≤ 30 W, with overvoltage and overcurrent protection |

| Environmental Specifications | Operating temperature: 0 °C–55 °C (optional -20 °C–70 °C); relative humidity: 5%–95% (non-condensing); shock resistance: 15 g; vibration resistance: 10 Hz–2 kHz |

| Dimensions/Weight | Approximately 380 mm × 280 mm × 120 mm; weight: approximately 7 kg |

| Certifications | CE, UL, CSA, and ISO 9001 quality management system certification |

3. Product Features

- All-in-One Design: The PC motherboard, display, and keyboard/button panel are housed in a single chassis, eliminating the need for external cables and enabling quick installation and commissioning.

- Industrial-Grade Reliability: The front panel has an NEMA 4/4X/12 protection rating for dust and water resistance. Internal components use high-temperature soldering and reinforced wiring for shock and vibration resistance.

- Open Architecture: Supports standard PC/AT BIOS and operating systems such as Windows XP, Windows 7 Embedded, and Linux, ensuring compatibility with common industrial automation software.

- Rich I/O Interfaces: Multiple serial ports, Ethernet, and USB interfaces meet the on-site connection needs of various sensors and actuators.

- Optional Modular Expansion: Additional I/O cards, communication modules (e.g., CAN, Profibus), or dedicated control cards can be selected based on on-site requirements.

- Easy Maintenance: Both the front and rear panels can be quickly removed, and internal components use snap-in installation for convenient on-site replacement or upgrading.

4. Structure and Composition

- Chassis: Die-cast metal housing with built-in cooling fans and heat sinks.

- Motherboard: Integrates CPU, northbridge/southbridge chips, memory slots, hard drive interfaces, and I/O control chips.

- Display Module: 15-inch LCD with LED backlighting; touch function is optional.

- Operation Panel: Integrates a keyboard/buttons, with reserved positions for LED indicators on the panel.

- Power Supply Module: 24 V DC input, with internal rectification, voltage stabilization, and filtering circuits.

- Cooling System: Combined fan and heat sink setup to ensure thermal management in high-temperature environments.

5. Typical Application Areas

| Industry | Specific Scenarios | Value Proposition |

|---|---|---|

| Injection Molding | Machine control panels, process monitoring | Provides real-time display of temperature, pressure, and displacement, along with human-machine interaction operations. |

| Packaging Machinery | Automatic packaging line control stations | Connects to PLCs and sensors via multiple serial ports to achieve high-speed data collection and control. |

| Textile Machinery | Textile machine monitoring systems | Offers vibration resistance, dust resistance, and water resistance to adapt to dusty workshop environments. |

| Metal Processing | CNC machine tool operation interfaces | High reliability ensures long-term continuous operation. |

| Energy and Power | Power distribution cabinet monitoring, on-site instruments | Compatible with industrial protocols such as Modbus and Profibus. |

| Logistics Automation | AGV (Automated Guided Vehicle) control units | Compact size and low power consumption make it suitable for mobile platforms. |

6. Installation and Maintenance Guidelines

Pre-Installation Inspection

- Verify that the power supply voltage is correct and the grounding is in good condition.

- Check that all connectors (I/O, display, keyboard) are securely fastened.

Mounting Method

- Secure the chassis to the rack or panel using bolts or industrial clips to ensure shock resistance.

- Align the front panel protective cover with the NEMA 4/4X/12 sealing groove.

Wiring and Connection

- Use shielded cables to connect high-speed communication ports such as RS-485 and CAN to avoid electromagnetic interference.

- All power cables should use connectors that comply with the IEC 60320 standard.

Initial Power-On and Self-Test

- After power-on, the system will automatically perform a POST (Power-On Self-Test). A green indicator light indicates normal hardware operation.

- Check the status of memory, hard drive, and I/O through the BIOS or pre-installed system tools.

Daily Maintenance

- Clean the internal dust of the chassis every 6 months and check the speed of the cooling fans.

- Regularly inspect the anti-corrosion condition of the interfaces and replace rust-proof gaskets if necessary.

- Use officially provided firmware packages for software upgrades to avoid compatibility issues caused by unauthorized versions.

Troubleshooting

- No Display: Check the backlight power supply and LCD connection cables; confirm whether the graphics card driver is loaded.

- Communication Abnormalities: Replace RS-232/RS-485 cables and check if the terminal resistors are properly matched.

- System Restarts: Check the power supply voltage stabilization and confirm if there is overload or short circuit.

————————————————————————————————————-

If you would like to learn more about our products and services, please feel free to contact us at any time!

- Sales Manager : Jinny

- Email : sales5@xrjdcs.com

- Whatsapp/Mobile:+86 15359273791

Global renowned brand cooperation

ABB 丨 GE 丨Allen Bradley 丨 Honeywell 丨 Emerson 丨 Bently Nevada 丨 Westinghouse

Triconex 丨 Foxboro 丨 ICS Triplex 丨 Hima 丨 Schneider 丨 Yokogawa 丨 Woodward

—————————————————————————————

Our Company: Product Range & Service Pledges

As a professional supplier, our company focuses on providing 100% original imported spare parts for four key industrial systems—DCS, PLC, industrial robots, and large – scale servo systems. These parts are sourced from leading global brands, including FOXBORO, EMERSON, TRICONEX, XYCOM, BENTLY, ROCKWELL, ABB, GE, Aen – Brady, YOKOGAWA, HONEYWELL, RELIANCE, SCHNEIDER, MODICON, Westinghouse, WOODWARD, Motorola, Rexroth, and SEW. Additionally, we specialize in procuring hard – to – find, out – of – production accessories to meet customers’ urgent or specialized needs.

Our Service Pledges to Customers

- Pledge 1: We are committed to delivering products with consistent quality and exceptional after – sales support. While upholding strict quality standards, we strive to offer competitive and reasonable pricing to maximize customer value.

- Pledge 2: All products are sourced or procured in compliance with national or industry standards, ensuring they meet the required performance criteria. When used correctly, our products will have a service life comparable to or exceeding that of other similar products on the market. We also provide professional guidance to help customers select the most suitable product types and specifications based on their specific requirements.

- Pledge 3: (Note: The original content for Pledge 3 was not provided. To ensure the completeness of our service commitments, we recommend supplementing details such as technical consultation, customization support, or post – purchase training here.)

- Pledge 4: We prioritize on – time delivery. Under normal circumstances, customers can expect to receive their orders within 6 working days. For special cases (e.g., urgent orders, custom parts), we will work with customers to negotiate a flexible delivery timeline that aligns with their needs.

- Pledge 5: Since all products are manufactured by original overseas factories, after – sales service is provided directly by these manufacturers. The standard warranty period typically ranges from 6 months to 1 year, with specific terms subject to the original manufacturer’s policies. If a product experiences quality issues, and both parties confirm the problem stems from the manufacturer’s defects, we will facilitate the return of the product to the original factory for repair or arrange alternative solutions (e.g., replacement) as needed.

About Our Company

Our company boasts strong technical capabilities, a comprehensive range of equipment, and advanced testing methods—all of which ensure our products are reliable and high – performing. Guided by the principle of “putting customers first,” we maintain strict delivery schedules, offer fair pricing, deliver top – quality products, and provide thorough after – sales service. Over the years, this commitment has enabled us to build long – term, trustworthy partnerships with numerous new and existing customers. Our products stand out for their reliable performance and unique advantages, earning us the trust and preference of clients across various industries.

Write your message here and send it to us