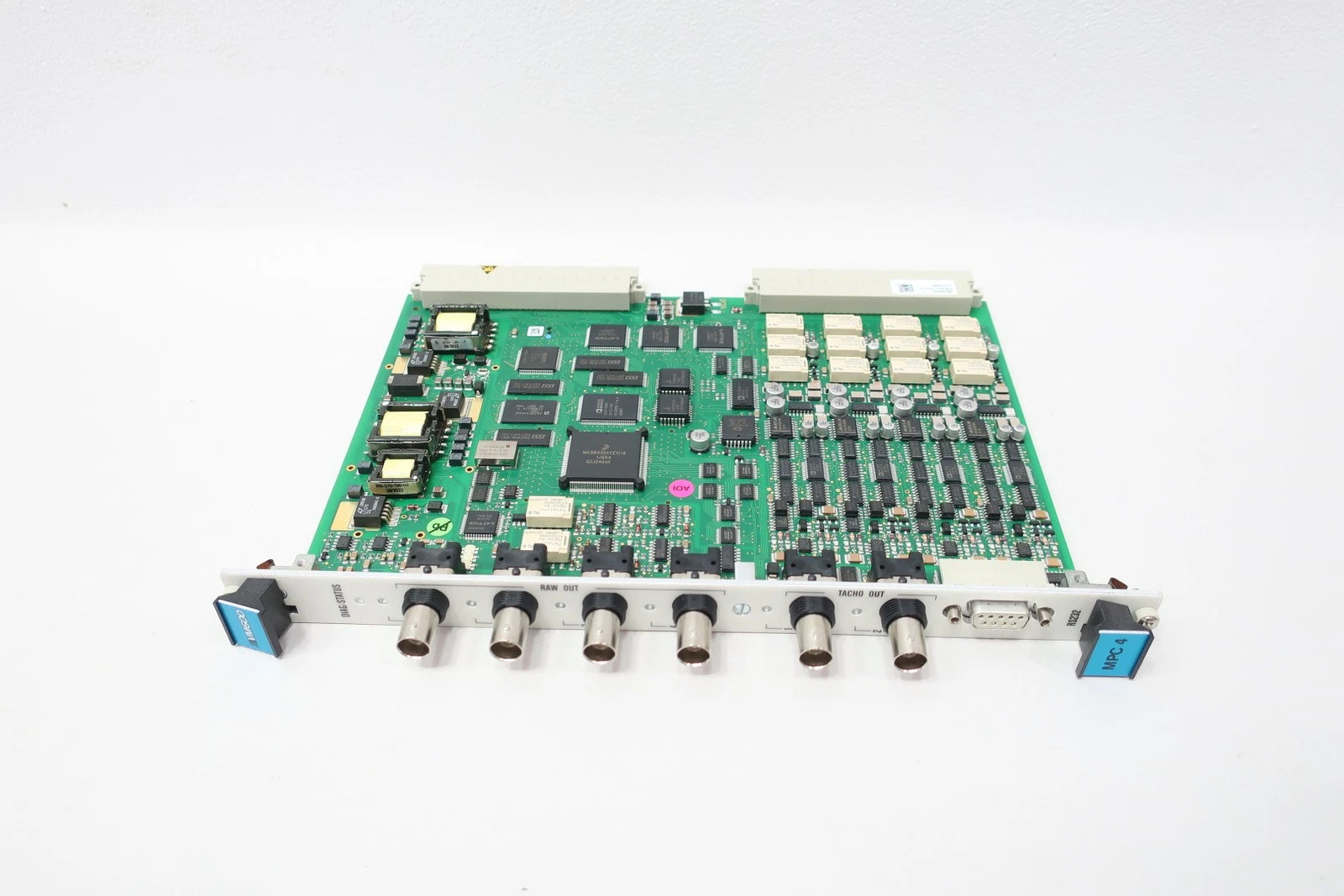

Vibro Meter 200-510-078-115 Mechanical Protection Card

Vibro Meter 200-510-078-115

The Mechanical Protection Card (MPC4) Model 200-510-078-115, part of Vibro-Meter’s VM600 series, is specifically designed for online monitoring and protection of critical rotating machinery. As the core module of the VM600 Mechanical Protection System (MPS), it real-time collects, processes, and reports dynamic signals such as vibration, speed, and displacement, enabling continuous equipment condition assessment and fault early warning.

Key Technical Specifications

- Model/Part Number: 200-510-078-115 (MPC4)

- Channel Configuration: 4 dynamic signal channels + 2 speed channels, all independently programmable

- Signal Types: Multiple sensor inputs including acceleration, velocity, and displacement (proximity probe)

- Processor: DSP-based high-speed digital signal processor with programmable broadband/narrowband filters

- Measurement Range: Covers a wide vibration frequency band from low to high frequencies, meeting monitoring needs of different machinery

- Dimensions/Weight: Approximately 26 × 16 × 5 cm, weight about 0.56 kg

- Operating Environment: Waterproof and dustproof housing, suitable for harsh industrial field conditions

Product Features

- Continuous Online Protection: The card remains online at all times, monitoring in real-time and triggering protective actions immediately when abnormalities occur.

- High-Precision DSP Sampling: Adopts advanced digital signal processing technology to ensure accuracy and real-time performance of measurement data.

- Flexible Multi-Channel Configuration: 4 dynamic channels and 2 speed channels can be freely programmed according to on-site requirements, compatible with multiple sensors.

- Programmable Filtering: Supports custom settings of broadband and narrowband filters to adapt to different spectral characteristics.

- Synchronous Amplitude-Phase Monitoring: Acquires both amplitude and phase information simultaneously in order tracking mode, providing a more comprehensive mechanical condition profile.

- Modular Structure: Plug-and-play compatibility with other VM600 system modules (CPU, backplane, communication card) for easy system expansion.

Structure and Composition

- MPC4 Mechanical Protection Card (core processing unit)

- Backplane/Rack (ABE04x/ABE056): Provides power supply, backplane communication, and mechanical support.

- CPU/Communication Module (CPUx): Responsible for system configuration, data aggregation, and interface with SCADA/DCS.

- Front-End Sensors: Accelerometers, velocity meters, proximity probes, pressure sensors, etc., selected based on on-site needs.

- VibroSight Software: Used for parameter setting, real-time monitoring, historical data analysis, and report generation.

Typical Application Fields

- Steam turbines and gas turbines in power plants

- Pumps, compressors, and fans in petrochemical industry

- Aero-engines and rail transit traction motors

- Critical bearings and gearboxes of mining and heavy machinery

- Any high-speed rotating equipment requiring continuous vibration monitoring and mechanical protection

Installation and Maintenance Guidelines

- Installation Location: The card should be installed in the rack backplane to ensure good heat dissipation and avoid strong magnetic field interference.

- Power Supply and Grounding: Use power supplies complying with IEC 60320 standard and ensure proper grounding to prevent electromagnetic noise.

- Sensor Arrangement: Select appropriate sensors based on equipment vibration characteristics, with stable fixing methods that do not affect measurement direction.

- Software Configuration: Perform channel mapping, threshold setting, and alarm logic programming via VibroSight. On-site calibration is recommended before initial commissioning.

- Regular Inspection: Check the connection status of the card and backplane, operation of cooling fans, and tightness of sensors every 6-12 months.

- Firmware Upgrade: The manufacturer regularly releases DSP firmware and software updates. Upgrade during maintenance windows to obtain the latest features and security patches.

If you would like to learn more about our products and services, please feel free to contact us at any time!

- Sales Manager : Jinny

- Email : sales5@xrjdcs.com

- Whatsapp/Mobile:+86 15359273791

Global renowned brand cooperation

ABB 丨 GE 丨Allen Bradley 丨 Honeywell 丨 Emerson 丨 Bently Nevada 丨 Westinghouse

Triconex 丨 Foxboro 丨 ICS Triplex 丨 Hima 丨 Schneider 丨 Yokogawa 丨 Woodward

—————————————————————————————

What Sets Us Apart

- Authenticity Guaranteed: We exclusively supply 100% original imported products, with strict quality checks to ensure compliance with original manufacturer standards, eliminating the risk of counterfeits.

- Obsolete Parts Specialists: We excel in sourcing hard-to-find, discontinued industrial components—solving critical replacement challenges for clients with legacy equipment.

- Swift & Reliable Delivery: Leveraging our optimized logistics network, we ensure fast shipment and accurate lead time estimates, minimizing operational downtime for our customers.

- Direct Sourcing & Strong Inventory: As a direct source supplier, we cut out unnecessary middlemen. Our in-stock inventory exceeds 100 million RMB, enabling immediate fulfillment of most orders.

Frequently Asked Questions (FAQs)

Q: Is there a warranty for the products you sell?

Q: Do you offer technical support for the components you supply?

Q: Do you maintain your own inventory, or do you only act as a trading intermediary?

Q: Are the products you offer new and original, or are they refurbished?