Welcome to our websites!

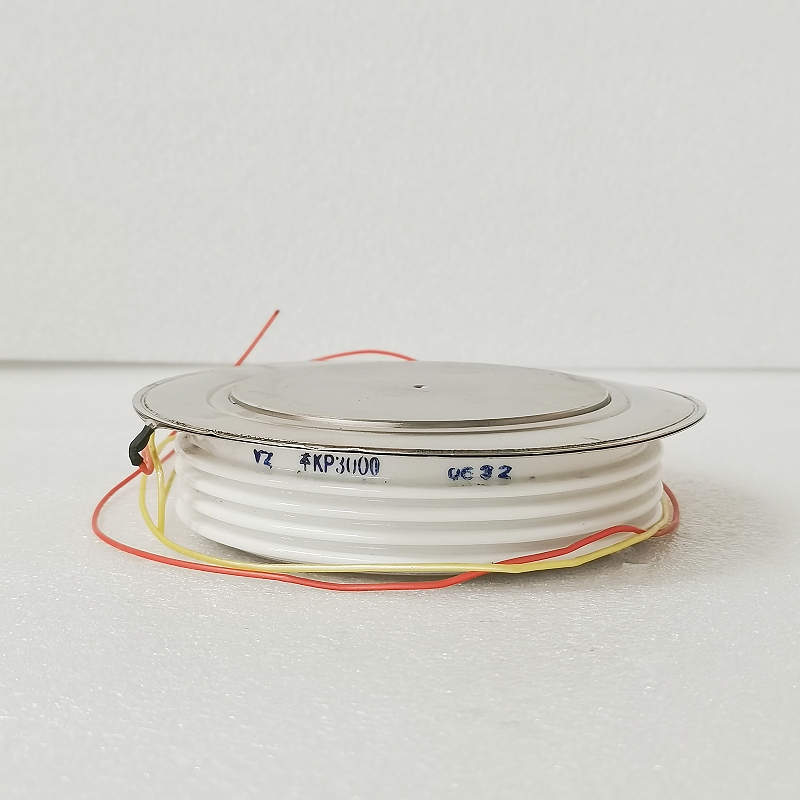

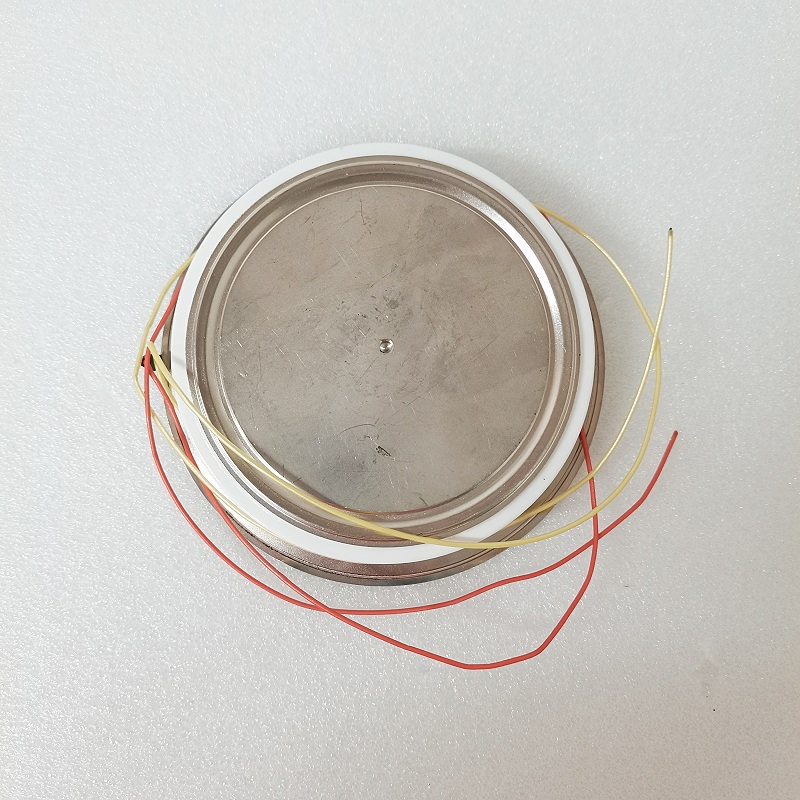

ABB KP3000 modular keyboard

ABB KP3000

I. Overview

ABB KP3000 is a high-performance modular keyboard designed specifically for industrial control systems, providing a user-friendly interface. It aims to offer operators a robust, durable, and ergonomic way to interact with automation systems, enabling precise control and monitoring of industrial processes. In addition, ABB KP3000 is also a high-performance power control component, widely used in power electronics, industrial automation, and energy management systems.

II. Parameters

The parameters of ABB KP3000 vary depending on specific models and application scenarios, but typically include the following:

Display type: KP3000 is usually equipped with a high-resolution color display, providing clear visual effects and an intuitive interface.

Keyboard configuration: The keyboard features a modular design, which can be customized and expanded according to specific application requirements.

Connectivity: KP3000 offers multiple connection options, such as wired or wireless interfaces, ensuring seamless integration with industrial control systems.

Voltage: The rated voltage of the thyristor in KP3000 is 3000V, and the rated current is 3000A.

Trigger current: 15~50mA.

Trigger voltage: 3~5V.

Turn-off time: 25 μS.

Input voltage: 24V DC.

Output voltage: 0 ~ 10V DC.

Communication interface: RS485.

Operating temperature range: -10℃~ 60℃.

Overall dimensions: 100mm × 80mm × 30mm.

Product net width: 120mm.

Product net depth/length: 135mm.

Product net height: 60mm.

Product net weight: 0.44kg.

Keyboard configuration: The keyboard features a modular design, which can be customized and expanded according to specific application requirements.

Connectivity: KP3000 offers multiple connection options, such as wired or wireless interfaces, ensuring seamless integration with industrial control systems.

Voltage: The rated voltage of the thyristor in KP3000 is 3000V, and the rated current is 3000A.

Trigger current: 15~50mA.

Trigger voltage: 3~5V.

Turn-off time: 25 μS.

Input voltage: 24V DC.

Output voltage: 0 ~ 10V DC.

Communication interface: RS485.

Operating temperature range: -10℃~ 60℃.

Overall dimensions: 100mm × 80mm × 30mm.

Product net width: 120mm.

Product net depth/length: 135mm.

Product net height: 60mm.

Product net weight: 0.44kg.

III. Product Features

Ease of use: KP3000 is designed intuitively with a user-friendly interface, and the clear display allows operators to control industrial processes quickly and easily.

Customizability: The modular design allows customization of keyboard layouts and functions to meet specific application needs.

Durability: The keyboard is designed to withstand harsh industrial environments, ensuring reliable operation under challenging conditions.

Integration capability: KP3000 seamlessly integrates with various industrial control systems, ensuring compatibility and efficient operation.

High performance: ABB KP3000 modules typically feature high reliability and performance, capable of stable operation in harsh industrial environments.

Easy integration: The module design is easy to integrate into existing automation and control systems, simplifying the installation and commissioning process.

Flexibility: By configuring different parameters and settings, the module can adapt to different application requirements and control strategies.

Safety: The module usually has multiple protection and safety features to ensure the safety and stability of operation.

DC power supply: Suitable for application scenarios requiring DC power supply, with good stability and low ripple, improving system reliability and stability.

Modular design: The KP3000 series can adopt a modular design, facilitating users to expand and upgrade according to actual needs, improving system flexibility, and reducing maintenance and upgrade costs.

Rich functionality: The operating unit may have multiple functions, such as overload protection, short-circuit protection, and undervoltage protection, to ensure the safe operation of electrical equipment and systems.

Easy integration: ABB KP3000 125V DC Operating Unit may have standard interfaces and communication protocols, making it easy to integrate and communicate with other equipment and systems.

Customizability: The modular design allows customization of keyboard layouts and functions to meet specific application needs.

Durability: The keyboard is designed to withstand harsh industrial environments, ensuring reliable operation under challenging conditions.

Integration capability: KP3000 seamlessly integrates with various industrial control systems, ensuring compatibility and efficient operation.

High performance: ABB KP3000 modules typically feature high reliability and performance, capable of stable operation in harsh industrial environments.

Easy integration: The module design is easy to integrate into existing automation and control systems, simplifying the installation and commissioning process.

Flexibility: By configuring different parameters and settings, the module can adapt to different application requirements and control strategies.

Safety: The module usually has multiple protection and safety features to ensure the safety and stability of operation.

DC power supply: Suitable for application scenarios requiring DC power supply, with good stability and low ripple, improving system reliability and stability.

Modular design: The KP3000 series can adopt a modular design, facilitating users to expand and upgrade according to actual needs, improving system flexibility, and reducing maintenance and upgrade costs.

Rich functionality: The operating unit may have multiple functions, such as overload protection, short-circuit protection, and undervoltage protection, to ensure the safe operation of electrical equipment and systems.

Easy integration: ABB KP3000 125V DC Operating Unit may have standard interfaces and communication protocols, making it easy to integrate and communicate with other equipment and systems.

IV. Structure and Composition

The structure and composition of ABB KP3000 include:

Rack: The basic chassis for installing all modules, with no address switches or backplane polarization comb settings. Modules can be installed in any position, supporting panel or panel mounting.

Power Supply: With a universal design, it can operate within a wide range of international power supply voltages, providing power for local controller modules or rack interface modules, and supporting up to 12 I/O modules.

Local Controller Module (LCM): The core part that runs real-time control programs defined offline on PC-based programming stations, controlling all I/O, PID control, communication, operation interface, and time sequence events.

Rack Interface Module (RIM): Expands the number of I/O, allows the installation of additional racks, and processes messages from I/O modules under the control of the local controller.

I/O Modules: Provide interfaces with the factory, with various modules available for direct sensor interfaces, sensor and actuator connections, and digital I/O for alarms, switches, and interlocks.

Communications Modules: Increase the number of serial ports and support various communication protocols, including PLCs and remote instruments. High-speed network modules are under development to achieve fast real-time data exchange between multiple PC3000 systems or with supervisory production control computers.

Operator Panels: Provide a runtime interface, allowing monitoring and display of important process parameters and supporting operator data input. They range from 2-line 40-character displays to PC-based supervisory systems.

Power Supply: With a universal design, it can operate within a wide range of international power supply voltages, providing power for local controller modules or rack interface modules, and supporting up to 12 I/O modules.

Local Controller Module (LCM): The core part that runs real-time control programs defined offline on PC-based programming stations, controlling all I/O, PID control, communication, operation interface, and time sequence events.

Rack Interface Module (RIM): Expands the number of I/O, allows the installation of additional racks, and processes messages from I/O modules under the control of the local controller.

I/O Modules: Provide interfaces with the factory, with various modules available for direct sensor interfaces, sensor and actuator connections, and digital I/O for alarms, switches, and interlocks.

Communications Modules: Increase the number of serial ports and support various communication protocols, including PLCs and remote instruments. High-speed network modules are under development to achieve fast real-time data exchange between multiple PC3000 systems or with supervisory production control computers.

Operator Panels: Provide a runtime interface, allowing monitoring and display of important process parameters and supporting operator data input. They range from 2-line 40-character displays to PC-based supervisory systems.

V. Application Fields

ABB KP3000 is widely used in the following fields:

Process automation: Widely applied in process automation systems that require monitoring and control of complex industrial processes.

Manufacturing industry: In industries such as automotive, food processing, and chemical engineering, it provides operators with a robust and ergonomic means of controlling production lines.

Energy management: Used in energy management systems, allowing operators to monitor and control energy generation, distribution, and consumption.

Infrastructure management: Suitable for infrastructure management systems such as water and wastewater treatment plants, transportation systems, and building automation.

Industrial automation: Used in motor drive and control to improve production efficiency and product quality.

Energy management: Applied in power management and optimization to achieve energy conservation and emission reduction.

Renewable energy: Used in inverters of solar and wind energy systems to improve energy conversion efficiency.

Electric vehicles: Utilized in battery management systems of electric vehicles to enhance battery performance and lifespan.

Power systems: In power systems, it is used for protecting and controlling power equipment such as transformers, circuit breakers, and switches.

Transportation: In the transportation field, it is used to control traffic signals, rail transit systems, etc.

Metallurgy, chemical industry, petroleum, and natural gas: In these fields, it is used in industrial automation and control systems.

Manufacturing industry: In industries such as automotive, food processing, and chemical engineering, it provides operators with a robust and ergonomic means of controlling production lines.

Energy management: Used in energy management systems, allowing operators to monitor and control energy generation, distribution, and consumption.

Infrastructure management: Suitable for infrastructure management systems such as water and wastewater treatment plants, transportation systems, and building automation.

Industrial automation: Used in motor drive and control to improve production efficiency and product quality.

Energy management: Applied in power management and optimization to achieve energy conservation and emission reduction.

Renewable energy: Used in inverters of solar and wind energy systems to improve energy conversion efficiency.

Electric vehicles: Utilized in battery management systems of electric vehicles to enhance battery performance and lifespan.

Power systems: In power systems, it is used for protecting and controlling power equipment such as transformers, circuit breakers, and switches.

Transportation: In the transportation field, it is used to control traffic signals, rail transit systems, etc.

Metallurgy, chemical industry, petroleum, and natural gas: In these fields, it is used in industrial automation and control systems.

VI. Installation and Maintenance

Installation: The installation of ABB KP3000 needs to comply with strict safety specifications, including checking power voltage and connections, installing overcurrent protection devices, protecting terminals, installing safety devices, avoiding operations inside the product, disconnecting the power supply in case of abnormalities, prohibiting misuse, improper repair, natural disasters, harmful gases, abnormal voltage, or use of power supplies other than specified, etc.

Wiring: Installation and wiring need to follow detailed technical specifications, including tightening torque, installation of waterproof seals, and panel cutting and installation methods.

Maintenance: The maintenance of ABB KP3000 includes regular inspection and cleaning to ensure the normal operation of the equipment. It is recommended to clean labels with isopropyl alcohol and external surfaces with mild soapy water.

Warranty: The warranty period of ABB KP3000 is one year from the date of purchase. If a fault occurs under normal use conditions, free repair will be provided (limited to Japan). However, faults caused by misuse, improper repair, natural disasters, harmful gases, abnormal voltage, or use of power supplies other than specified will be repaired for a fee.

Wiring: Installation and wiring need to follow detailed technical specifications, including tightening torque, installation of waterproof seals, and panel cutting and installation methods.

Maintenance: The maintenance of ABB KP3000 includes regular inspection and cleaning to ensure the normal operation of the equipment. It is recommended to clean labels with isopropyl alcohol and external surfaces with mild soapy water.

Warranty: The warranty period of ABB KP3000 is one year from the date of purchase. If a fault occurs under normal use conditions, free repair will be provided (limited to Japan). However, faults caused by misuse, improper repair, natural disasters, harmful gases, abnormal voltage, or use of power supplies other than specified will be repaired for a fee.

———————————————————————————————————————————

If you would like to learn more about our products and services, please feel free to contact us at any time!

- Sales Manager : Jinny

- Email : sales5@xrjdcs.com

- Whatsapp/Mobile:+86 15359273791

Global renowned brand cooperation

ABB 丨 GE 丨Allen Bradley 丨 Honeywell 丨 Emerson 丨 Bently Nevada 丨 Westinghouse

Triconex 丨 Foxboro 丨 ICS Triplex 丨 Hima 丨 Schneider 丨 Yokogawa 丨 Woodward

—————————————————————————————

Choose us, and you will enjoy the following advantages:

- One-stop procurement: We offer a wide range of industrial control products to meet all your purchasing needs.

- Professional solutions: Our technical team will tailor the optimal solutions for you.

- Considerate services: We will provide pre-sales, in-sales and after-sales services throughout the entire process.

Additional strengths:

- Over 20 years of industry experience

- Authorized agent for many well-known brands

- A rich product line covering multiple industries

- A professional technical team providing all-round services

- A sound after-sales service system to protect customers’ rights and interests

We sincerely welcome you to call or send an E-mail for consultation.

Write your message here and send it to us